Performance and Advantages

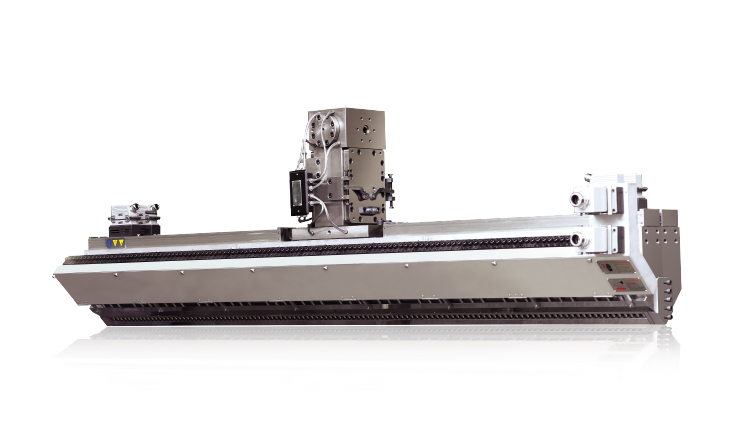

· Suitable for producing various specifications of plastic medical bed headboards, footboards, and guardrails.

· Equipped with a high-output extrusion system and an accumulator-type die head.

· Optional JW-DB single-station hydraulic screen changer system based on raw material conditions.

· Customizable template specifications according to the size of the product.

| Model | Unit | BM100 | BM160 |

| Max Product Volume | L | 100 | 160 |

| Dry Cycle | Pc/h | 360 | 300 |

| Die Head Structure | Accumulating type | ||

| Main Screw Diameter | mm | 100 | 100 |

| Max Plasticizing Capacity (PE) | Kg/h | 240 | 240 |

| Driving Motor Power | Kw | 90 | 90 |

| Accumulating Volume | L | 12.8 | 18 |

| Oil Pump Motor Power (Servo) | KW | 22 | 22 |

| Clamping Force | KN | 600 | 800 |

| Space Between Platen | mm | 500-1300 | 500-1400 |

| Platen Size W*H | mm | 500-1300 | 1120*1200 |

| Max Mold Size | mm | 800*1200 | 900*1450 |

| Heating Power of Die Head | KW | 30 | 30 |

| Machine Dimension L*W*H | m | 5.5*2.5*4.0 | 7*3.5*4 |

| Machine Weight | T | 16 | 20 |

| Total Power | KW | 135 | 172 |

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others