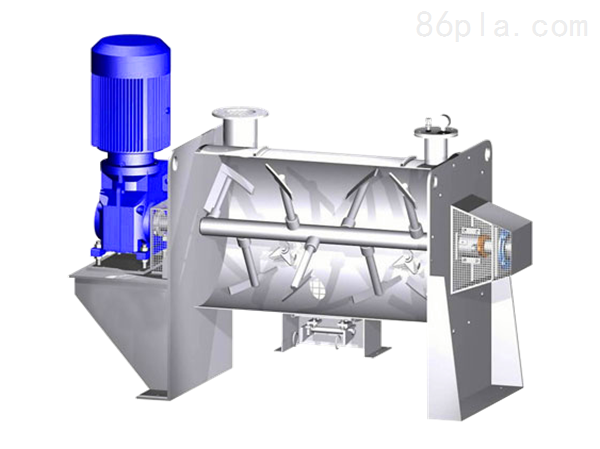

Brief Description: The plastic internal mixer, also known as a kneader, is primarily used for the mastication and compounding of rubber. This machine features a pair of specifically shaped rotors that rotate relative to each other, intermittently processing polymer materials under adjustable temperature and pressure in a sealed environment. It mainly consists of a mixing chamber, rotors, rotor sealing devices, feeding and pressing devices, discharging devices, transmission systems, and a base.

Plastic Internal Mixer Introduction:

Also known as a kneader, it is primarily used for the mastication and compounding of rubber. This machine features a pair of specifically shaped rotors that rotate relative to each other, intermittently processing polymer materials under adjustable temperature and pressure in a sealed environment. It mainly consists of a mixing chamber, rotors, rotor sealing devices, feeding and pressing devices, discharging devices, transmission systems, and a base.

This machine achieves deep pre-mixing of materials, ensuring they reach a mature state, especially beneficial for heat-sensitive and shear-sensitive materials. Effective pre-mixing facilitates better dispersion, reducing the requirements for subsequent mixing processes and minimizing the risk of material degradation.

Principle:

During operation, the two rotors rotate relative to each other, gripping the material fed from the feed opening and pulling it into the gap between the rollers. The material is subjected to compression and shearing by the rotors, then split into two parts upon encountering the sharp edges of the lower top wedge. These parts travel along the gaps between the front and rear chamber walls and the rotors before returning to the roller gap above.

Plastic Internal Mixer Precautions:

1. Regularly check the insulation of all electrical lines and pay attention to the warning signs on the machine.

2. Do not use your hands or metal rods to clear blockages in moving parts or the mixing chamber; instead, use a plastic rod carefully.

3. Be cautious of hot surfaces to avoid burns.

4. If powder leakage or screeching from the seal ring occurs, first evenly loosen the four screws, then retighten them slightly. Add some lubricating oil or engine oil to the rotor gap in the mixing chamber and run the machine unloaded for 3-5 minutes while gently tapping around the edge of the seal ring cover with a hammer. If leakage persists, adjust individual spring tensions. If the seal ring cover is very close to the side plate water channel of the mixing chamber, it indicates that the inner seal ring is worn and needs replacement. Refer to the manual for instructions on replacing the seal ring.

5. Pay special attention to checking gear oil, engine oil, and grease levels and lubrication status daily. Ensure the oil level in the three-in-one oil cup does not fall below half.

6. In case of machine failure, stop the machine immediately. Unauthorized personnel should not perform any actions. Notify and wait for qualified maintenance personnel to inspect and repair the machine.

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others