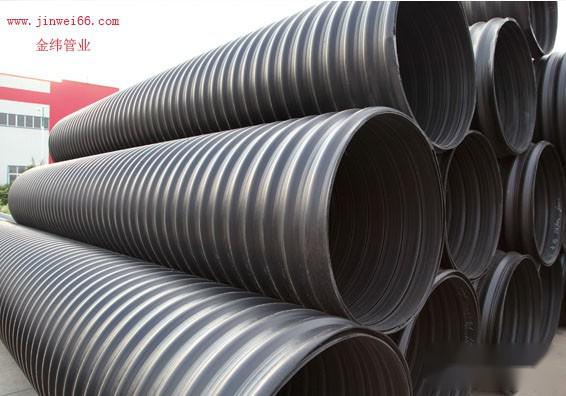

HDPE steel belt reinforced spiral corrugated pipes combine the corrosion resistance of plastic and the toughness of steel, making their advantages obvious:

●Avoids the problem of cracking at the lap joints of single-layer structures

●High ring stiffness, with various specifications achievingSN8 and above

●Saves material costs, significantly reducing costs compared to all-plastic buried drainage pipes of the same diameter and ring stiffness

●Combination of steel and plastic: Uses unique bonding materials, with each layer securely and reliably bonded in a molten state

●Easy to construct, with excellent performance: Compared to traditional drainage pipes, it offers reliable sealing, long service life, flexibility, seismic resistance, lightweight, and convenient and fast construction

| No. | Item | Requirement | |

| 1 | Ring Stiffness (KN/㎡) | SN8 | ≥8 |

| SN10 | ≥10 | ||

| SN12.5 | ≥12.5 | ||

| SN16 | ≥8 | ||

| 2 | Impact Performance (TIR) | ≤10% |

|

| 3 | Ring Flexibility | Sample is smooth, no reverse bending, no cracking |

|

| 4 | Oven Test | No delamination or cracking at the weld of the drainage pipe |

|

| 5 | Creep Ratio | ≤2% |

|

| 6 | Tensile Strength of the Weld | Nominal Size/mmNominal Diameter | Minimum Tensile Force the Pipe Can Withstand (N) |

| 300≤DN/ID≤500 | 600 | ||

| 600≤DN/ID≤800 | 840 | ||

| 900≤DN/ID≤1200 | 1020 | ||

| 1300≤DN/ID≤2000 | 1460 | ||

| DN/ID≤2000 | 1600 | ||

| 7 | Ring Flexibility | Sample is smooth, no reverse bending, no cracking | |

| 8 | Oven Test | No delamination or cracking at the weld of the drainage pipe | |

| 9 | Creep Rate |

≤2% |

|