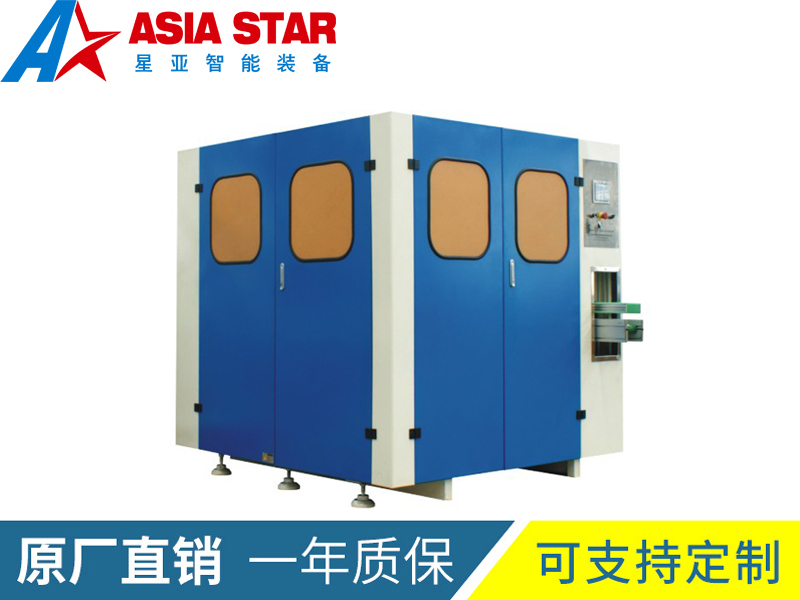

Product Description

This series of pulverizers developed by our factory incorporates foreign technology and is designed for high-density PE, EVA, SBS, ABS, and other plastics that have been successfully tested. Therefore, this equipment is ideal for plastic product manufacturers to reduce costs, save on expenses, and address the accumulation of waste products. It is suitable for PVC, PE, PET recycled materials. It is used for fine grinding of various plastics, especially for processing thermoplastic PVC and PE recycled materials. Practical operations in specialized plastic product factories have proven that adding 20%-30% of the ground powder to processing formulas maintains the chemical and physical properties of new materials without any changes.

Features of the Plastic Pulverizer:

The fully automatic series of plastic pulverizers belongs to the disc-type plastic pulverizer series, characterized by high output and low energy consumption. It is used for grinding polyethylene (PE), polypropylene (PP), polystyrene (PS), ABS, and other materials into powders.

● New disc design with high output, excellent wear resistance, and a lifespan twice that of ordinary discs.

● Uses specially designed bearings to achieve high-speed operation.

● Easy installation and maintenance; simply open the door cover for cleaning, and shut down the exhaust fan for unloading, reducing the labor intensity of operators.

● Equipped with a dust collection system, effectively reducing dust pollution. The grinding process is fully sealed, preventing dust leakage.

● Fully automated, including automatic feeding, discharging, and sorting.

● Simple adjustment of grinding clearance using feeler gauges and adjustment bolts for precise control.

● The main unit cooling system uses a combination of air and water cooling, significantly lowering the working temperature inside the machine. This prevents material discoloration and facilitates the grinding of heat-sensitive plastics such as some PE, EVA, SBS, and ABS.

● Reasonably designed, with a smaller cross-sectional area of the grinding chamber, materials are immediately captured and finely ground upon entry, then quickly removed to avoid overheating and decomposition, resulting in higher output.

Working Principle of the Plastic Pulverizer:

1. The working part of the machine is the blade disc. High-speed particles collide with fixed blades and teeth, partially breaking down the material. The finer particles are extracted by the suction fan, while larger particles continue to collide until they are fully crushed and extracted. This reduces the load on the blade disc, improves grinding efficiency, and ensures uniform cooling of the powder.

2. Low temperature is a major advantage of this machine. According to thermal equivalence: each hour of operation generates 860 kilocalories of heat. The machine uses external exhaust with a wind volume of 50 cubic meters per kilowatt. The temperature difference between the inlet and outlet removes most of the heat, with a small portion cooled by water.

For materials with less stringent grinding requirements, an economical series of plastic pulverizers can be selected. Based on the original design, it omits the functions of powder screening and automatic return of substandard powders. The MFJ-L series, with its reasonable design, provides convenience for grinding powders with less strict requirements.

Product Specifications

Industry Applications