1. Introduction to PE Water Supply Pipes:

PE water supply pipes are made from special polyethylene raw materials that are extruded into shape using a plastic extruder. They are used in urban water supply networks, irrigation projects, and agricultural sprinkler systems, especially suitable for environments that are acid and alkali resistant and corrosion resistant. Because PE pipes use hot melt and electric fusion connections, they achieve integration between the joints and the pipes, effectively resisting hoop stresses and axial impact stresses generated by pressure. Moreover, PE pipes do not contain heavy metal salt stabilizers, making the material non-toxic, non-scaling, and resistant to bacteria, thus avoiding secondary contamination of drinking water.

2. Production Standards for PE Water Supply Pipes: GB/T13663-2000 (pipes) GB/T13663.2-2005 (fittings). Sanitary Standard: "Health and Safety Performance Evaluation Standard for Drinking Water Supply and Distribution Equipment and Protective Materials" GB/T17219.

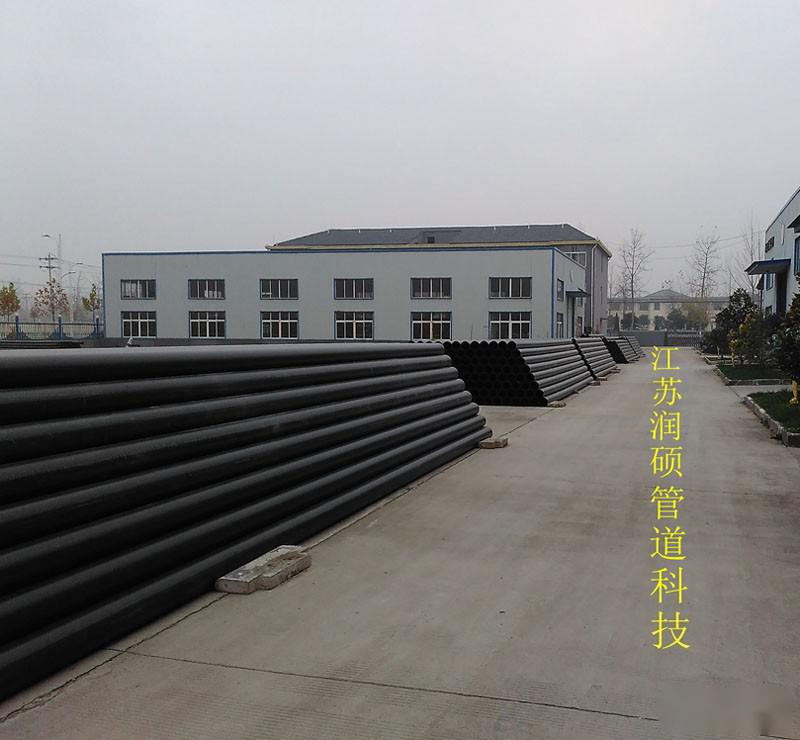

3. Appearance Description and Materials of PE Water Supply Pipes:

Black pipe with blue stripes. Produced using PE80 and PE100 grade raw materials, generally used for pressure water transportation.

4. Application Areas of PE Water Supply Pipes:

● Urban tap water supply network systems;

● Industrial raw material transportation pipeline systems;

● Landscape irrigation supply network systems;

● Systems for the renovation of old networks;

● Sewage discharge pipe systems;

● Sand and slurry transportation systems;

● Agricultural irrigation pipeline systems.

5. Main Advantages of PE Water Supply Pipes:

1. Good sanitary performance: No heavy metal salt stabilizers are added during the processing of PE water supply pipes, making the material non-toxic, without scaling, and resistant to bacteria, effectively solving the issue of secondary contamination in urban drinking water;

2. Long service life: Under standard conditions, PE water supply pipes can be safely used for at least fifty years;

3. Excellent corrosion resistance of polyethylene pipes;

4. Smooth inner walls and non-scaling pipe walls, with ultra-low friction, allowing for a 30% increase in flow rate compared to steel pipes of the same diameter;

5. Excellent wear resistance, with a wear resistance four times that of steel pipes;

6. Good toughness, making it difficult to rupture even under severe deformation, thus providing excellent earthquake resistance;

7. Lightweight, flexible polyethylene pipes with superior construction performance and lower construction costs;

8. Recyclable and reusable polyethylene pipes, with complete combustion releasing no toxins, making them environmentally friendly and sanitary;

9. Polyethylene materials contain no harmful components, do not rust or scale, making them safe and sanitary for drinking water pipes;

10. PE water supply pipes utilize hot melt and electric fusion welding, making them easy to operate, with secure joints and no leaks.

6. Welding Steps for PE Water Supply Pipes: The welding of PE water supply pipes can be divided into several crucial steps. Please pay close attention.

(1) When welding PE water supply pipes, align the axes of the two pipes and first spot weld the ends of the two pipes to fix them.

(2) For welding PE water supply pipes to flanges, insert the water supply pipe into the flange, then spot weld and align with a square ruler before welding. Both sides of the flange should be welded, and the inner side should not protrude beyond the flange sealing surface.

(3) If the wall thickness of the PE water supply pipe is more than 5mm, a bevel should be cut to ensure full penetration welding. Bevel shaping can be achieved by gas welding or using a beveling machine, but slag and oxidized iron must be removed, and the surface must be ground until metal shine is visible.

(4) When cutting steel pipes, the cut surface should be perpendicular to the centerline of the pipe to ensure concentricity after welding.

(5) The flange should be perpendicular to the centerline of the pipe, and the surfaces should be parallel. The flange gasket should not protrude into the pipe, and the bolt specifications connecting the flange should match the flange. The length of the bolt protruding from the nut should not exceed 1/2 of the bolt diameter.

(6) When welding water supply pipes, remove rust, dirt, and grease from the pipe joints.

(7) Flange gaskets should be selected according to drawings and specifications, with rubber gaskets used for cold water systems and asbestos rubber gaskets for hot water systems.