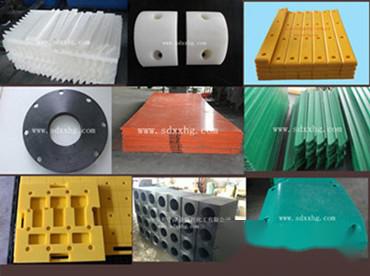

CNC Machining Ultra High Molecular Weight Polyethylene Special-Shaped Parts Manufacturing Process

Shandong Ningjin Xinxing Chemical Co., Ltd. has 8 large hydraulic presses, 4 new electric cutting machines, 3 thickness machines, 4 CNC engraving machines, 4 large milling machines (6m X 2m), and 2 small drilling and milling machines, 6 bench drills. We possess advanced production and testing equipment in the industry. We can process according to customer drawings and samples. We have a professional production team, an independent technical department, and a laboratory with strict quality control. We strive to achieve excellence. As long as it is special-shaped parts made of ultra high molecular weight polyethylene material, we can process them accurately for you!

The largest Ultra High Molecular Weight Polyethylene Sheet production base, a high molecular polyethylene sheet manufacturer, is striving to become a top 500 company in ultra high molecular weight polyethylene sheet production - Shandong Ningjin Xinxing Chemical Co., Ltd.!

Main products include: Ultra High Molecular Weight Polyethylene Sheet, high molecular polyethylene sheet, high molecular polyethylene wear-resistant liners, high wear-resistant coal bin liners, fender facing panels, UHMW_PE sheets, dock anti-collision panels, coal bin liners, UPE sheets, ultra high molecular weight polyethylene special-shaped parts, polyethylene special-shaped parts, etc.

We can provide full sheets and process various specifications and models of special-shaped parts and components according to drawings and customer requirements! Shandong Xinxing strives for excellence, Your satisfaction is our pursuit!!! We adhere to the concept of customer satisfaction, using continuous improvement as a means to eliminate defective products from reaching customers, which is our eternal pursuit. Let both suppliers and demanders benefit and win together!

Excellent Characteristics of Ultra High Molecular Weight Polyethylene Special-Shaped Parts:

1. Ultra high molecular weight polyethylene sheets have the best wear resistance among plastics, and the larger the molecular weight, the higher the wear resistance and impact resistance of the material;

2. The impact strength of ultra high molecular weight polyethylene sheets is high among existing plastics, and it retains considerable impact strength even at 70°C;

3. Self-lubricating, low friction coefficient, energy-saving, with a wax-like feel.

4. Extremely low water absorption. Therefore, its physical and mechanical properties are not affected by the humidity factors in the working conditions.

5. Ultra high molecular weight polyethylene sheets are chemically stable and can resist corrosion from various corrosive media and organic solvents such as acids, alkalis, and salts within certain temperature and concentration ranges.

6. Ultra high molecular weight polyethylene sheets are odorless, non-toxic, and have no corrosiveness, with physiological recyclability and adaptability.

7. Non-stick property;

8. When the molecular weight of high-density polyethylene exceeds 500,000, the embrittlement temperature drops to 140°C. Ultra high molecular weight polyethylene can even maintain certain mechanical strength at temperatures as low as -269°C under liquid nitrogen.

Wide Range of Applications for Ultra High Molecular Weight Polyethylene Sheets:

1. Linings: coal bin liners, hoppers, chutes, wear-resistant plates, brackets, sliding surfaces, rollers, etc.;

2. Food machinery: guide rails, star wheels, guide gears, rollers, bearing liners, etc.;

3. Papermaking machinery: suction box covers, flow guiding plates, scraper plates, water wings;

4. Chemical industry: sealing filler plates, filling materials, vacuum molds, pump components, bearing liners, gears, sealing joint surfaces;

5. Assembly line machinery: turntables, guide rails, wear-resistant strips, curved guide rails, magnetic bends, chain guide rails, gears;

6. Others: agricultural machinery, ship parts, electroplating industry, extremely low-temperature mechanical components, etc.

7. Large cranes and heavy machinery: placed under the legs of large cranes for support.

8. Used as port fender boards, anti-collision boards, and buffer boards to prevent ships from colliding with the dock.

If you find the above introduction not detailed enough, or if you cannot find the product you want, feel free to call us or visit our factory for guidance and inspection! Phone: 0534-5223277 13173333540 QQ: 2875013107 Xinxing Chemical Zhang Longzhen!