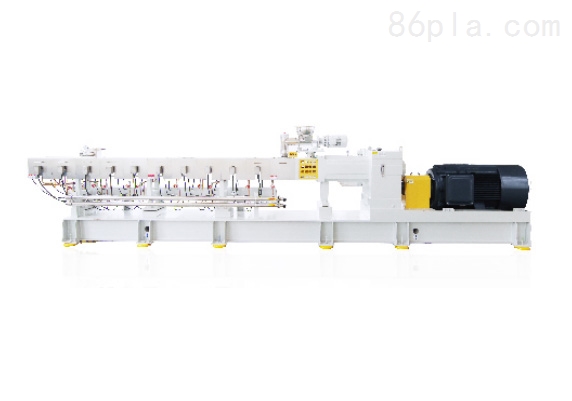

Brief Description: The black masterbatch pelletizing machine is primarily used for processing waste plastic films, woven bags, convenience bags, basins, buckets, beverage bottles, furniture, daily household items, etc. It is suitable for the majority of common waste plastics and is widely used in the waste plastic regeneration industry. This machine is versatile, popular among users, and is a preferred choice for plastic recycling.

The black masterbatch pelletizing machine is primarily used for processing waste plastic films, woven bags, convenience bags, basins, buckets, beverage bottles, furniture, daily household items, etc. It is suitable for the majority of common waste plastics and is widely used in the waste plastic regeneration industry. This machine is versatile, popular among users, and is a preferred choice for plastic recycling.

Before starting the machine, inspect all mechanical and electrical components to ensure that no connection bolts are loose; check if the lubrication points are properly lubricated, if the transmission device is functioning normally and safely, if the protective devices are intact, and if the electrical instruments are sensitive. Ensure that the motor carbon brushes maintain good contact.

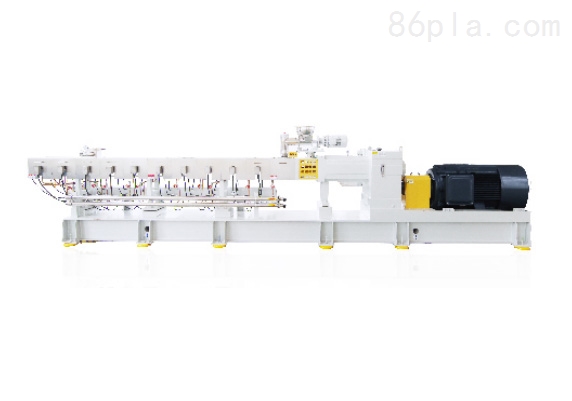

Next, let's introduce the basic principles of screw element arrangement for the black masterbatch pelletizing machine:

1. In the meshing area, the speed of the screws is opposite. One screw pulls material into the meshing gap, while the other pushes it out. This results in the material transferring from one screw to another in an "∞" shape. Due to the small gap in the meshing area and the opposite direction of thread and groove speeds, there is a high shear rate, providing excellent self-cleaning action by scraping off any adhered material. This ensures a short residence time for the material, making this equipment ideal for compounding and pelletizing.

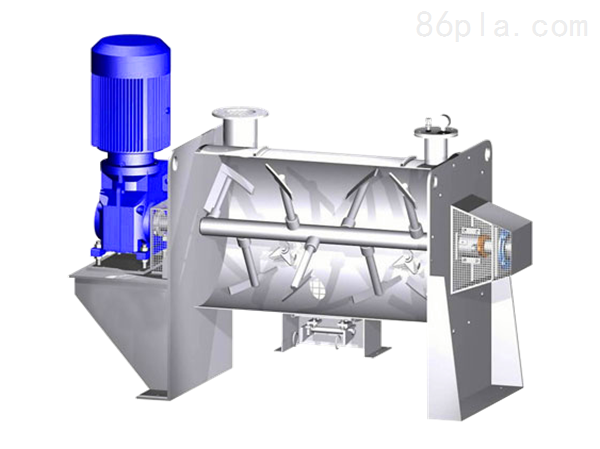

2. Melting Section: Gear discs and kneading discs can accelerate the melting and mixing of materials. Generally, forward conveying elements are used to separate mixing elements to avoid significant temperature gradients in the melting zone.

3. Mixing Section: For distribution mixing, narrow plates with smaller misalignment angles are used. For dispersion mixing, wide plates with larger misalignment angles, left-handed conveying kneading discs, or multi-tooth gear discs are used.

4. Degassing Section: Before the degassing port, reverse-threaded elements are typically set up to block the melt, ensuring the screw grooves are filled. For extruders used for devolatilization drying, multiple degassing ports can be set up using alternating reverse kneading discs and reverse-threaded elements. In the middle of the degassing section, large-pitch conveying elements with deep grooves are usually placed.

5. Melt Conveying Section: Gear disc elements can improve the homogenization quality of the melt, while small-pitch threaded elements can enhance positive conveying capacity.

When performing waste plastic recycling, the black masterbatch pelletizing machine is essential. Do you know how to repair mold damage during production? Let's take a look:

1. For molds used for a long time, the sizing bushing or die lip may wear out over time, increasing the inner diameter. In such cases, replace the sizing bushing with a newly manufactured one. If the die lip is severely worn, the working surface finish will be damaged and should be reground and rechromed.

2. If rust pits appear on the surface of the mold parts, grind them flat and then rechromed after polishing.

3. For large molds with deep pits on the working surface, use welding to fill the deficient areas, followed by grinding and polishing.

4. Minor scratches or burrs on mold parts can be removed using fine oilstone or fine sandpaper.