Technical Features

Special dual-cylinder clamping device design, fast mold opening and closing, short idle cycle time, high efficiency. Dual proportional hydraulic system, precise control, 25% energy saving compared to vane pump drive. Horizontal injection molding design, reliable plasticizing, simple operation. Single crossbeam locking mold system, easy mold installation.

Optional Features

Servo drive, 25%-45% energy saving. One-stop program in mold labeling solutions, saving labor and workshop costs, perfect adhesion, elegant appearance.

Application Areas

Machinery Accessories

Processing Principle

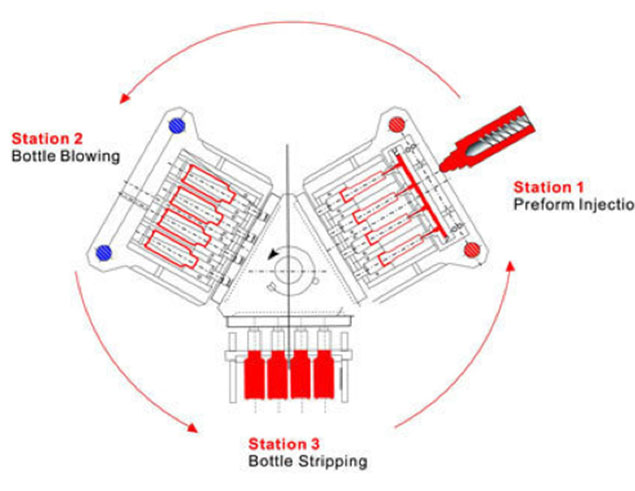

The injection blow molding machine is a specially designed machine with a rotating three-station indexer. After injection, the preform is sent to the blow station, then stripped for further processing such as washing or conveyor filling. Suitable for materials like PE, PP, PS, SAN, EVA, COC, PEEK, TPU, PETG, PET, with bottle capacities ranging from 1ml to 1000ml. The bottles have perfect neck finishes, strict body thickness and weight control, suitable for high-quality packaging in pharmaceuticals, cosmetics, home goods, and food packaging industries.

Main Technical Parameters

| Injection Unit | Unit | MSZ60S | |

| Screw Diameter | mm | 50 | 55 |

| Screw L/D Ratio | L/D | 23:01 | 23:01 |

| Maximum Injection Volume (HDPE) | g | 298 | 360 |

| Screw Speed | rpm | 10-235 | |

| Barrel Heating Power | KW | 10.8 | |

| Clamping System | |||

| Injection Clamping Force | KN | 750 | |

| Blow Clamping Force | KN | 89 | |

| Maximum Platen Size | mm | 740×390 | |

| Minimum Mold Thickness | mm | 280 | |

| Mold Heating Power | KW | 6 | |

| Ejection System | |||

| Ejection Stroke | mm | 200 | |

| Idle Cycle Time | sec | 3.5 | |

| Drive System | |||

| Drive Motor | KW | 30 | |

| System Pressure | Mpa | 15 | |

| Product Size Range | |||

| Product Volume | ml | 5-800 | |

| Product Height | mm | ≤200 | |

| Product Diameter | mm | ≤100 | |

| Other | |||

| Compressed Air Pressure | Mpa | 1 | |

| Compressed Air Flow Rate | M³/min | ≥0.8 | |

| Cooling Water Flow Rate | M³/h | 5 | |

| Rated Total Power (including mold heating) | KW | 46.8 | |

| Equipment Dimensions | M | 4.3×1.69×2.45 | |

| Net Weight of Equipment | ton | 8.6 | |

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app