Jiangsu Victor Machinery Co., Ltd.

China JiangsuProvince

Main products

Extrusion Molding, Precision Molds, Injection Blow Molds, PTFE Extrusion Production Line, Injection Blow Molding Machine, PTFE Base Tape Production Line, Plastic Extrusion Sheet Production Line

About Us

Sure, here is the translation of the provided information:

---

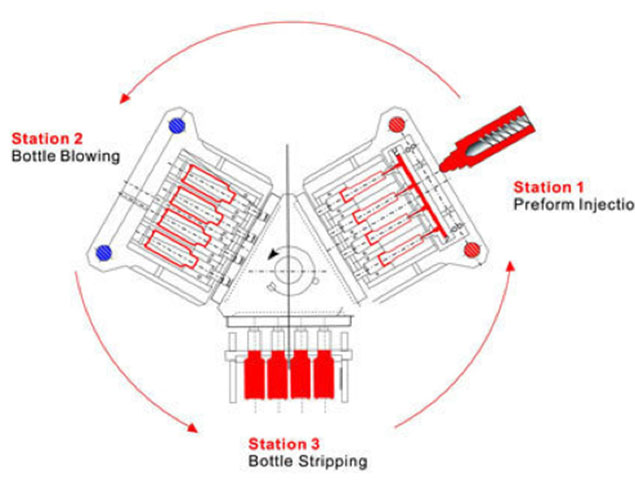

Jiangsu Weida Plastic Machinery Co., Ltd. (formerly known as Zhangjiagang Rubber and Plastic Machinery Factory) is one of the main companies under Jiangsu Weida Machinery Group Co., Ltd. It is a technology enterprise in Jiangsu Province and a designated production enterprise for plastic machinery by the Ministry of Light Industry, also a key backbone enterprise under the Jiangsu Provincial Light Industry Department. The company has been certified to ISO9000 quality management system. As the main member enterprise of the industrial enterprise association of Zhangjiagang City and one of the main initiators of the Zhangjiagang Plastic Machinery Association, it has made positive contributions to promoting the long-term and healthy development of the plastic industry in Zhangjiagang. The company mainly produces plastic machinery equipment and has won honors such as provincial excellence and national excellence. Among them, the injection-blowing hollow forming machine is one of the key technical development projects during the "Eighth Five-Year Plan" period and has won the Third Prize of National Science and Technology Progress Award; the PET film production line was the earliest in China to adopt the extrusion calendering method to produce transparent PET films, and has obtained three national patents. The company has successively developed and produced the injection-blowing hollow forming machine, the vertical injection-blowing hollow forming machine. The company always considers technological innovation as the basic decision for its development, especially focusing on the development of new products. To date, the company has formed a wide range of product series. This company provides complete sets of equipment and can undertake "turnkey" projects. Jiangsu Weida Plastic Machinery Co., Ltd. is located in Tangqiao Town, Zhangjiagang City, and is a member unit of the China Light Industrial Machinery Industry Association, a second-level qualified metrology unit, a provincial high-tech enterprise, and a medium-sized enterprise. The company (originally Zhangjiagang Rubber and Plastic Machinery Factory) was founded in 1958 and has gone through forty years of hard entrepreneurship, developing into a provincial enterprise group that spans regions, industries, and levels, integrating science, engineering, trade, and manufacturing. Currently, the company has over 600 employees, with fixed total assets of 60 million yuan, and the entire factory area covers an area of 70,000 square meters. At present, the company owns more than 250 main processing equipment, including large and medium-sized equipment such as a three-axis machining center imported from the United States and a laser cutting machine imported from Switzerland. Mr. Yijingdong, the general manager and legal representative of Jiangsu Weida Plastic Machinery Co., Ltd., sincerely welcomes partners from home and abroad to negotiate business and build glorious achievements together, creating a bright future! Attached are the main companies under Jiangsu Weida Machinery Group Co., Ltd.: Jiangsu Weida Plastic Machinery Co., Ltd., Jiangsu Weida Precision Mold (merged with Huafeng Precision Mold, still part of Jiangsu Weida Mold), Jiangsu Weida International Trade Department, Fenggang Knit Machinery Co., Ltd., Zhangjiagang Construction Machinery Co., Ltd., Zhangjiagang Liyuan Machinery Co., Ltd., Jiangsu Weida Precision Engineering Co., Ltd., Hualong Electric, and Luo Shi Technology Co., Ltd.

---

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code