LSP Liquid-State Polycondensation PET Recycling Pelletizing Equipment

【LSP PET IV Increase Solution】

LSP (Liquid State Polycondensation) enhances the quality of recycled PET materials (fibers, bottle flakes, films, low IV polymers), producing high-grade PET fibers, PET packaging straps, PET pellets, PET films, bottle-to-bottle recycling, and fiber-to-fiber recycling. This process improves resource recycling efficiency and product quality.

【Innovative Structure】

The innovative design of the reactor increases the polymerization reaction area, improves the flowability of PET melt, and shortens the reaction time.

【Smart Control】

With our new smart control system, operation and real-time monitoring are more convenient than ever, allowing for predictive maintenance and improved production efficiency.

【High Energy Efficiency】

Variable frequency equipment automatically adjusts operating frequency. A multi-level temperature control system minimizes heating energy consumption, reducing overall system operating costs.

【Excellent IV Improvement Effect of LSP】

Thanks to our excellent homogenization characteristics, the reactor can mix different raw materials into a uniform melt.

【Applicable Products】

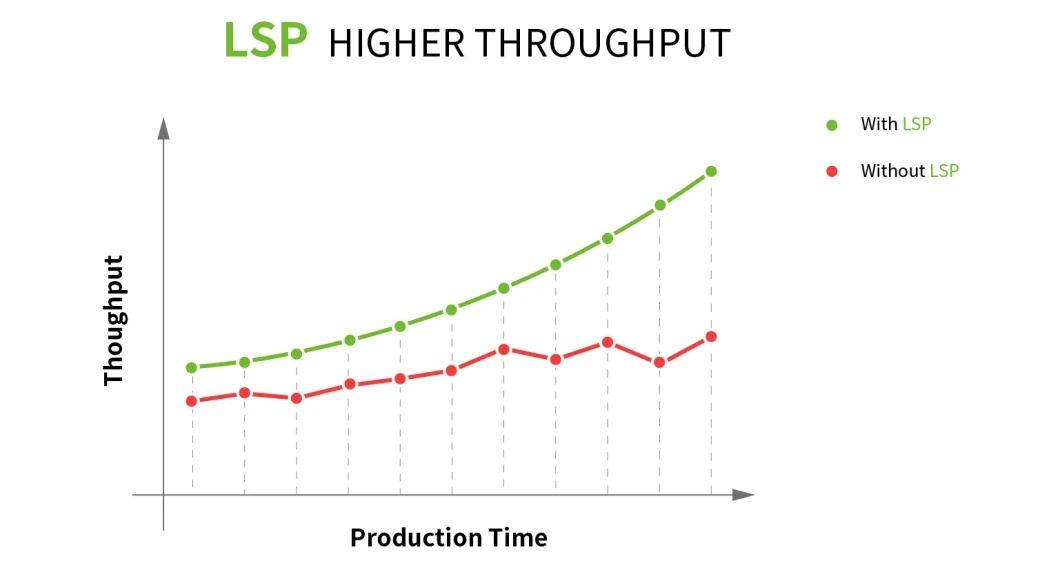

【Higher Throughput Achieved by LSP】

Through the buffer of our reactor, the entire production system becomes more controllable, increasing output and avoiding downtime during filter changes.

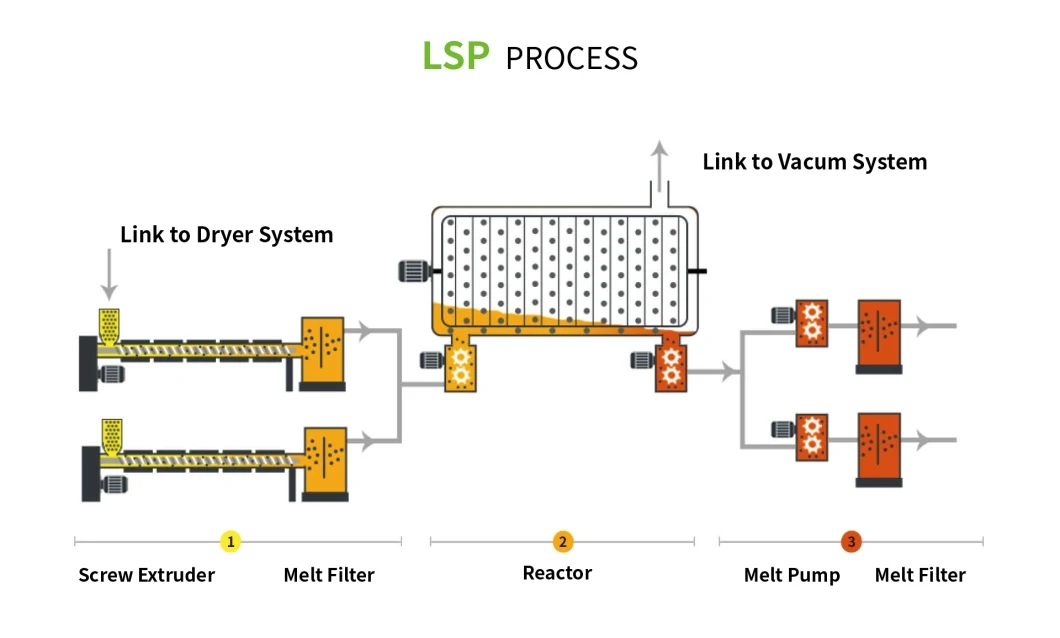

【LSP Working Principle】

LSP is a very effective alternative to solid-state polymerization (SSP) because it does not require energy to cool the polymer before reheating it. Additionally, the reaction time in the melt phase is much faster than in the solid phase, which contributes to the better economics of the LSPLINE™ system.

【Homogenization】

Due to the complex sources of recycled material, the composition is difficult to guarantee, leading to fluctuations in the melt during production. To stabilize the IV, the reactor operates at a certain speed, ensuring thorough mixing of the internal melt.

【Impurity Removal】

Since PET repolymerization occurs under high vacuum conditions, low molecular weight substances contained in the raw materials and additives will vaporize at high temperatures.

【Chain Growth】

There are still many hydroxyl and carboxyl groups in the raw materials, and the catalytic system remains effective. Under certain temperature and vacuum conditions, polymerization reactions continue to occur, increasing molecular chains and IV.

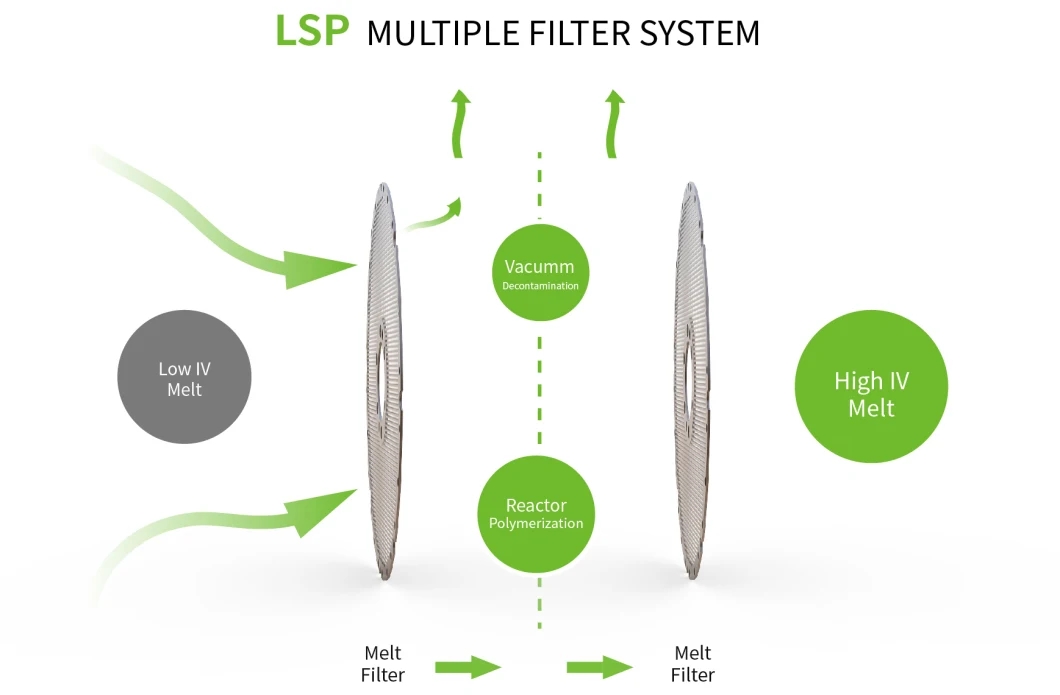

【LSP Multi-Stage Filtration System】

【Post-Extrusion】

The first melt filter after extrusion can remove inorganic impurities, facilitating further reactions.

【During Reaction】

Under high vacuum conditions, oligomers and decomposed gases separate from the melt and are discharged into the vacuum system.

【Post-Reaction】

High-viscosity melt passes through the final melt filter to remove inorganic impurities that remain in the melt.

【LSP High-Quality Products】

【High Purity】

After multiple filtrations and homogenization, the recycled polyester melt has higher purity and IV, resulting in more uniform color in the final product.

【High Strength】

Under high-temperature vacuum polymerization reactions, molecular chains and IV continue to increase, resulting in stronger polyester products.

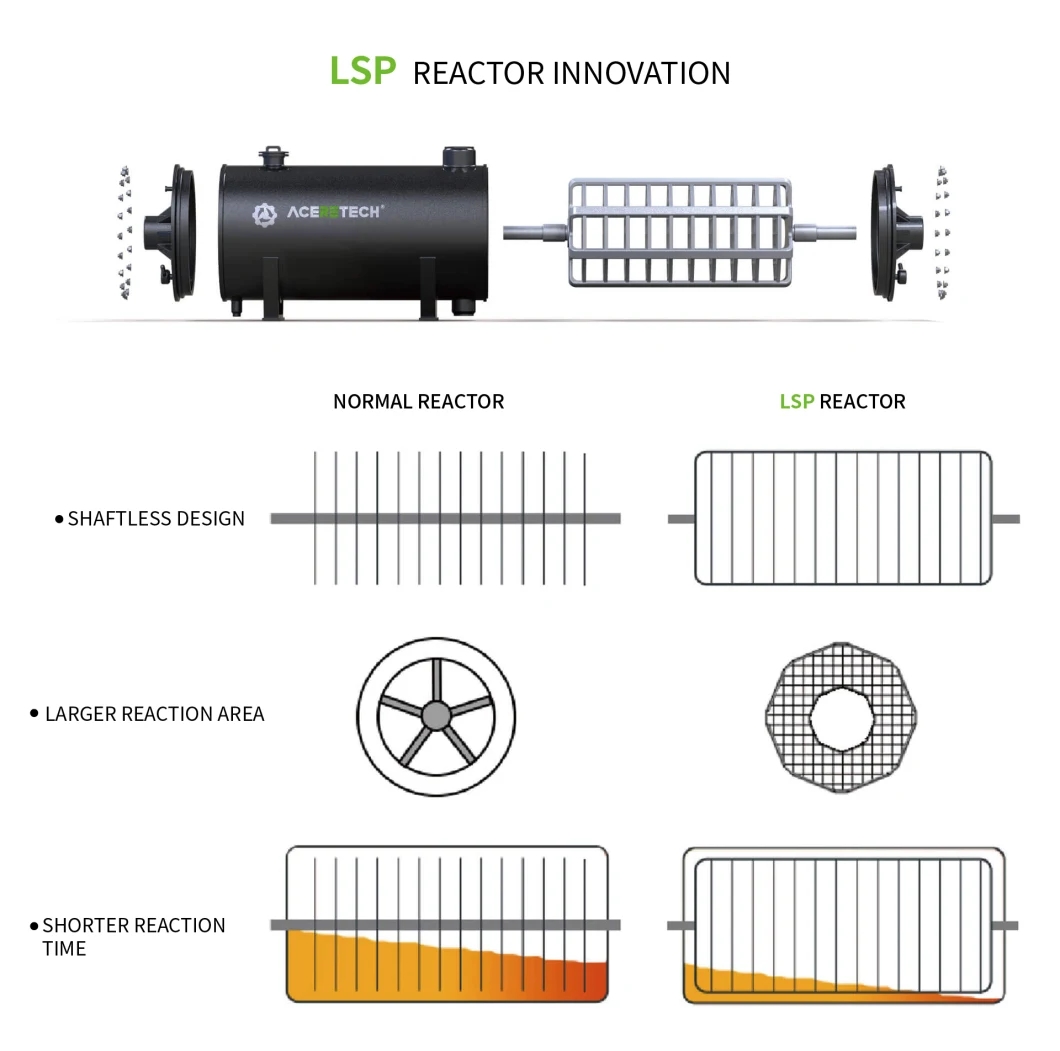

【LSP Reactor Innovation】

【Shaftless Design】

Unique shaftless design allows for smoother melt film reactions and avoids the risk of material accumulation.

【Larger Reaction Area】

A larger reaction area provides better contamination removal efficiency, better IV increase effect, and higher purity post-reaction.

【Shorter Reaction Time】

The innovative mesh design ensures smoother melt flow, more stable level control, extremely low liquid levels, shorter melt reaction times, and better finished product color.

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app