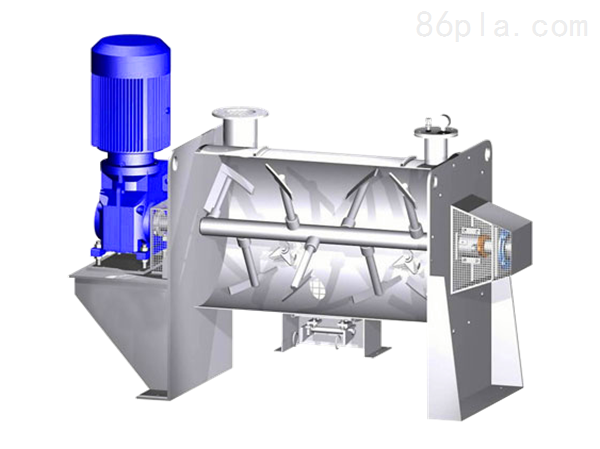

Brief Description: The low-speed mixer for production can be designed with a jacket structure, allowing hot oil to pass through and heat the material, causing additives to melt or drying the material.

Introduction to Low-Speed Mixer for Production:

This machine is also known as a cold mixer and comes in both horizontal and vertical designs. It has several main uses:

1. It can perform simple mixing of materials;

2. It can be designed with a jacket structure that allows water to pass through, cooling the material after hot mixing to reduce degradation;

3. It can be designed with a jacket structure that allows hot oil to pass through, heating the material to melt additives or dry it.

Installation:

1. The mixer and control box are installed separately on a concrete foundation and secured with anchor bolts.

2. The mixer is heated using resistance heating elements that transfer heat evenly to the pot via high-flashpoint mechanical oil inside the heating jacket. Power cables are connected via underground conduit.

3. Cooling is achieved using water, which passes through the outer jacket and cooling rings to ensure even cooling.

Precautions for Using the Low-Speed Mixer for Production:

1. Before starting the machine, read the user manual carefully to understand the basic operating requirements.

2. Mix materials up to 40% capacity, approximately 5 kilograms more.

3. Use a worm gear reducer, add lubricating oil before use, clean and change the oil after each use to prevent contaminants from entering the gearbox, and do not operate without oil.

4. Ensure the material submerges the agitator shaft, cover the hopper lid after adding material, and start the machine to avoid splashing.

5. Start the main motor and run it empty for a short while. Before running, check all connections for tightness, close the main power switch, and perform an empty run test. If there are no abnormalities, proceed to manually load and mix materials for production.

6. During operation, the material in the mixing chamber undergoes repeated movements under the rotation of the S-shaped agitator shaft. After several repetitions, different materials will be thoroughly mixed.

7. After use, clean any residual material from all parts of the mixer.

8. If the machine will not be used for a long time, wipe it down completely, apply rust preventive oil to the surfaces, and cover the entire mixer with a tarp. If used frequently, change the oil in the reducer every three months.

Finished Product Manufacturers

Finished Product Manufacturers

Finished Product Distributors

Finished Product Manufacturers

Finished Product Manufacturers