Nanjing Xintuo Intelligent Equipment Co., Ltd.

JiangsuProvince

Main products

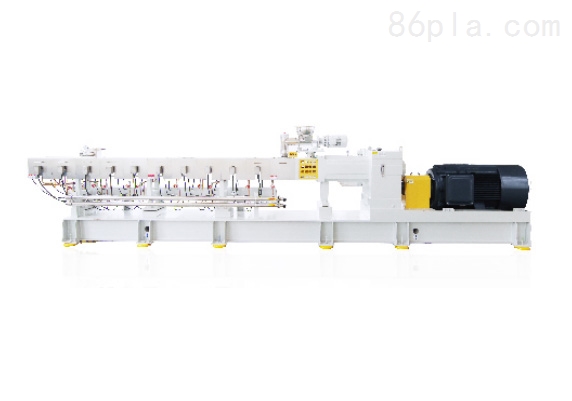

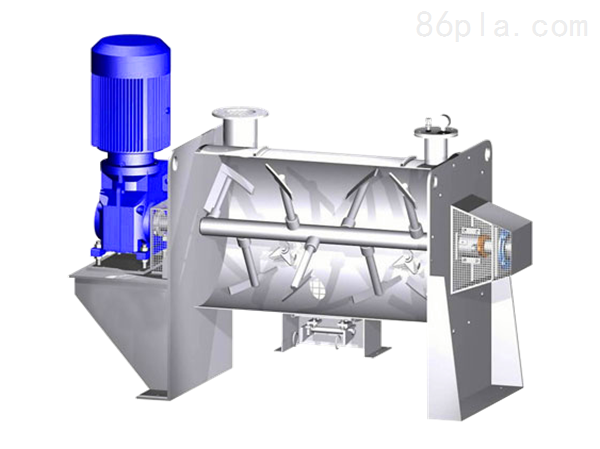

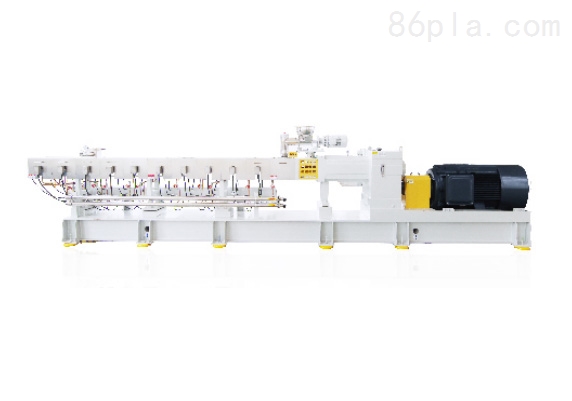

Screw extruder, plastic auxiliary systems

About Us

Nanjing Xintuo Intelligent Equipment Co., Ltd. was established on May 29, 2020, with Zhou Xianting as the legal representative. The registered capital is 10 million RMB, and the unified social credit code is 91320113MA21LF2H92. The company is located in the Baima Town Industrial Concentration Zone, Lishui District, Nanjing City. It belongs to the other manufacturing industry. Its business scope includes: Permitted projects: import and export of goods; import and export of technology (projects that require approval by relevant departments can only be carried out after obtaining such approval, specific business items are subject to the approval results). General projects: sales of intelligent material handling equipment; research and development of machinery and equipment; general equipment manufacturing (excluding special equipment manufacturing); specialized equipment manufacturing (excluding licensed specialized equipment manufacturing); sales of metal products; wholesale of electronic components; sales of instruments and meters; sales of artificial intelligence hardware; processing and sales of mechanical parts and components; general component manufacturing; sales of plastic products; production and sales of Class I medical devices; sales of Class II medical devices; sales of health supplies and disposable medical supplies; sales of special labor protective equipment; technical services, technical development, technical consultation, technical exchange, technology transfer, and technology promotion (except for projects that require approval, activities can be conducted independently according to the business license). The current operating status of Nanjing Xintuo Intelligent Equipment Co., Ltd. is active (in operation, open, registered).