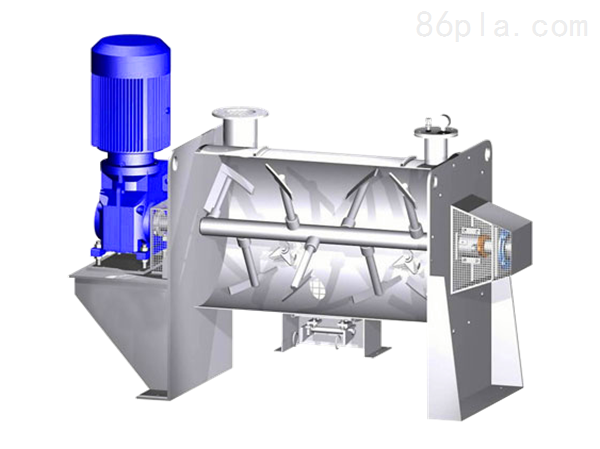

Brief description:The horizontal mixer consists of a U-shaped housing, helical ribbon agitator blades, and transmission components; the helical ribbon blades have a double-layered internal and external structure, with the outer layer spiraling to gather material from both sides towards the center, and the inner layer spiraling to convey material from the center to both sides, creating a convection mixing effect.

Horizontal mixerIntroduction:

It is composed of a U-shaped shell, helical ribbon agitator blades, and transmission components; the helical ribbon blades have a double-layered internal and external structure, with the outer layer spiraling to gather material from both sides towards the center, and the inner layer spiraling to convey the material from the center to both sides, forming a convection mixing.

The raw materials can be pre-mixed to a certain degree before being added to the twin-screw extruder. The main purpose is to ensure uniform mixing of the raw materials and to achieve certain process objectives, such as pre-plasticizing the resin, pre-absorbing additives, pre-wetting difficult-to-disperse powders, and partially dehydrating moisture-containing raw materials. Xintuo Machinery provides various mixing equipment and mixing solutions to meet the pre-mixing requirements of different material systems.

Performance Characteristics:

Compared to other mixers, it has the advantages of shorter mixing time, wider adaptability without damaging the mixed materials, and ease of cleaning. It does not compress or grind the materials, and it also shows good adaptability for mixing coarse and fine materials. Without damaging the state of the mixture, it generates a complex motion of lateral cross-flow, blending, and diffusion within the machine, achieving optimal mixing results in a short period.

Usage:

Widely used in various industries such as chemicals, battery materials, coatings, dyes, pesticides, pharmaceuticals, food, feed, additives, refractory materials, new materials, electronic plastics, ceramics, fertilizers, metallurgy, mining, dry mortar, and special building materials for the mixing of powders with solids and powders with liquids. The mixing efficiency is twice that of a conical mixer.

Horizontal mixerUse and Maintenance:

1. During operation, no hard foreign objects larger than 5mm should enter the machine; otherwise, the machine should be stopped to remove them. If any abnormal sounds such as metal clashing or friction are detected during operation, the machine should be stopped immediately for inspection and troubleshooting.

2. When mixing solids and liquids, start the operation first, then spray the liquid. After the liquid spraying is complete, continue to mix for 3-5 minutes.

3. The general mixing time for materials is about 5 to 8 minutes. The mixing time for special materials needs to be determined through user testing.

4. The particle size of the mixed material is 20 to 1400 mesh; the amount of liquid sprayed can be determined based on the adsorption properties of the material and the user's production process requirements.

5. During use, the lubricating oil for the reducer and bearings should be replaced regularly. The lubricant grade for the reducer should be selected according to the requirements in the reducer manual. The main shaft bearing should be lubricated with a composite lithium-based grease.

6. The shaft end seal uses a packing seal. The sealing material is generally oil-impregnated asbestos. If a small amount of leakage is detected during use, the gland bolts should be tightened.

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others