H KY/SKY series two-stage extrusion pelletizing units are mainly used for the modification, compounding, and pelletizing of heat-sensitive materials. They are commonly used for PVC cable compounds and XLPE peroxide cross-linked compounds, as well as soft PVC medical compounds, rigid PVC products, EVA foamed shoe soles, PE low-smoke halogen-free flame-retardant compounds, etc. The pelletizing methods primarily include air-cooled hot cutting and eccentric water mist cutting, and can also be equipped with strand cold cutting and water ring hot cutting.

● The twin-screw processing section is responsible for plasticizing, compounding, and homogenizing;

● An open, non-backpressure melt feed single-screw extruder allows for degassing during operation;

● Material is gently extruded through the die of the single-screw extruder;

● Pelletizing methods are selected based on material properties, including air-cooled cutting, eccentric water mist cutting, strand cutting, or water ring cutting;

● Low power consumption and small footprint;

● Fully automatic raw material compounding and pelletizing process, reducing labor costs;

● Simple operation, excellent safety, and stability.

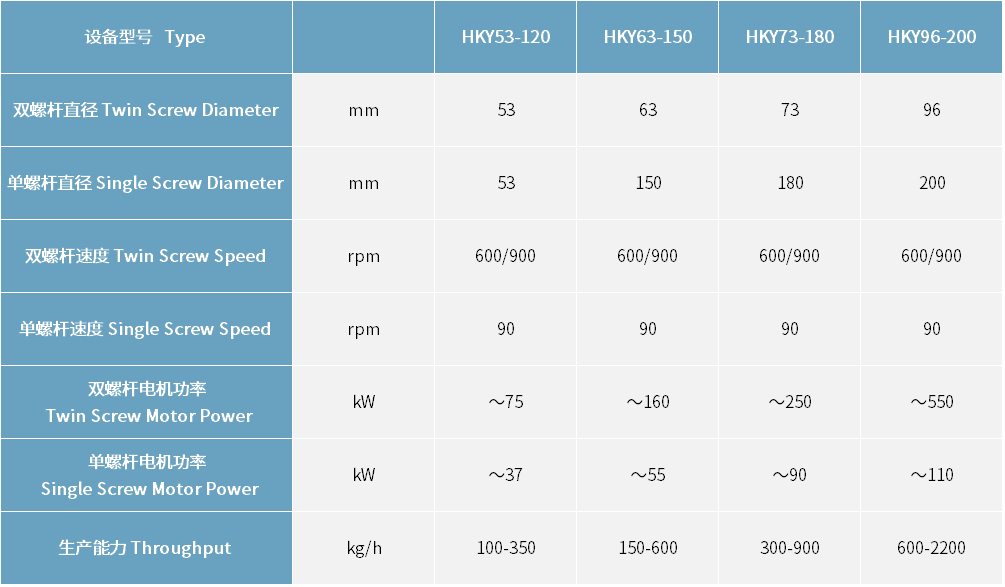

Technical Parameters

HKY Two-Stage Units

Application Fields

XLPE cable compounds, PVC cable compounds, shoe sole materials, transparent plastics, medical materials, low-smoke halogen-free or halogen-free flame-retardant cable compounds, EVA shielding compounds, PE/EVA carbon black masterbatch, etc.

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app