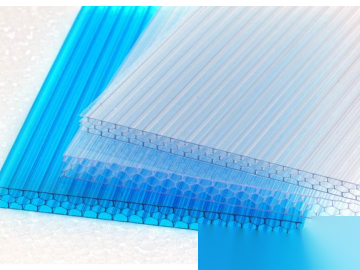

HANGMEI Polycarbonate Sheet how is the quality? HANGMEI polycarbonate sheets are made from imported Bayer materials from Germany, featuring flame retardancy, with a natural temperature resistance of 630 degrees Celsius. The combustion performance of PC sheets has been tested to meet the flame retardant B1 grade according to fire-resistant building material quality supervision and testing. In addition to its flame retardancy, the polycarbonate sheet also exhibits excellent chemical corrosion resistance. At room temperature, it can withstand corrosion from organic acids, inorganic acids, weak acids, vegetable oils, and neutral salt solutions, among others. Moreover, the polycarbonate sheet offers exceptional heat and cold resistance, adapting well to severe weather changes, whether high temperatures or cold. Additionally, the sheet has a high light transmittance, which varies with the color of the sheet. The impact resistance of the polycarbonate sheet is also outstanding, being eighty times that of ordinary glass. A prominent feature of the polycarbonate sheet is its safety; it does not shatter or break like glass, making it very safe and convenient to use.

In recent years, domestic manufacturers have produced many inferior polycarbonate sheets using recycled materials to lower costs and cater to low-end customer requests. This has resulted in many inferior sheets flooding the market, making it difficult for customers to distinguish between genuine and fake polycarbonate sheets. Based on pricing, the price discrepancy for polycarbonate sheets of the same standard from different brands indicates that there are differences in product quality.

HANGMEI company introduces some methods to identify whether the polycarbonate sheet is made from virgin materials.

Firstly, check the transparency; the light transmittance of quality polycarbonate sheets is around 94%. The lower the transparency, the more recycled material has been added, and inferior sheets often have a cloudy appearance.

Secondly, examine the flatness of the sheet; a flat sheet indicates thicker top and bottom walls, meaning more material is used and it's less likely to deform. On the other hand, better manufacturing techniques are reflected in the flatness. If there are waves present, it indicates that the technology is still immature or that the walls are thinner compared to each other.

Additionally, check the thickness of the top and bottom walls; the thicker they are, the more material is used, leading to a higher density and consequently higher costs, indicating better product quality.

Finally, you can peel back the protective film to inspect the sheet. A sheet free of impurities and particles is made from virgin materials, whereas sheets with impurities indicate the addition of recycled materials. The more recycled material added, the more visible the impurities, and the worse the quality of the sheet. Bending a polycarbonate sample that breaks easily indicates poor quality, suggesting it is not pure PC material but rather contains recycled materials.

Of course, with CHRONIC, you need not worry about the issue of recycled materials being mixed into the polycarbonate sheets.

We promise:

1. Quality Assurance

The polycarbonate sheets produced by HANGMEI not only have excellent quality but also come at very competitive prices. We have been producing and processing polycarbonate sheets for many years and have a professional production technology team. We guarantee the quality of our products!

2. After-sales Service

We have a comprehensive after-sales service system that we have always valued. If you have any questions or issues after purchasing or ordering our products, please promptly contact our customer service staff or technical engineers, and we will assist you in resolving them in a timely manner.

3. Logistics and Transportation

Polycarbonate sheets are lightweight and easy to transport. However, due to regional restrictions and other issues, please contact us after purchasing our products, and we will arrange convenient and fast logistics for you. For more detailed information about our products, visit our official website:

| http://www.hmsmygb.com |