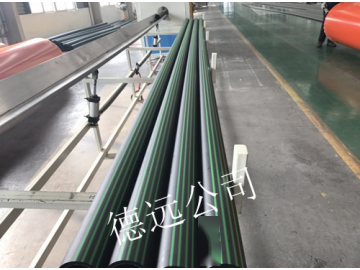

Henan Deyuan Rubber and Plastic Products Co., Ltd. produces leak-proof double-layer fuel pipes for gas stations with a full range of specifications, Φ32 Φ40 Φ63 Φ75 Φ110 Φ125 mm. The manufacturer ships directly, offering competitive prices and excellent after-sales service, with a professional installation team available for on-site guidance if needed.

Fuel pipe joints, fuel pipe fittings, gas station fuel pipes

My company specializes in: leak-proof double-layer fuel pipes for gas stations, fuel pipes, gas station fuel pipes, fuel pipe fittings, mainly including the following:

Double-layer tees Single-layer tees Double-layer welded joints Double-layer terminal welds (detection ports) Double-layer terminal welds Double-layer terminal welds (detection ports) Single-layer welded joints Transition copper joints Double-layer bends Single-layer bends Flanges Conductive plugs Welding machines + tools + pressure testing tools

Introduction to leak-proof double-layer fuel pipes for gas stations:

Traditional single-layer steel underground fuel pipelines require "five oils and four cloths" for reinforced anti-corrosion treatment, with all processes needing to be carried out on-site at the gas station. This not only complicates the process but also requires the construction unit to have good control over craftsmanship details; a slight oversight may lead to unsatisfactory results. In contrast, double-layer composite fuel pipes use new composite materials, with all pipelines, joints, tees, and other components prefabricated in the factory, allowing for direct on-site assembly of finished pipeline components, making the construction process simple and efficient. Additionally, the double-layer pipeline system is equipped with leakage monitoring and alarm devices, enabling the entire core process from the fuel tank to the fuel dispenser at the gas station to be monitored online throughout, ensuring safety and quality management.

Leak-proof double-layer fuel pipe systems utilize new technologies and materials in petrochemical equipment, boasting significant advantages over traditional single-layer steel tanks and single-layer seamless steel pipe fuel lines in terms of physical properties, corrosion resistance, and intelligent monitoring and operation.

Features of leak-proof double-layer fuel pipes:

1. The inner pipe is lined with EVOH resin, ensuring leak-proof performance.

2. The fuel pipes have a testing report issued by the National Chemical Building Materials Testing Center, guaranteeing quality.

3. The inner pipe has an anti-static layer, ensuring safe use of the pipeline.

4. Made from imported HDPE materials, ensuring product quality.

5. Rated operating pressure is 1MPa, rated operating temperature: -40°C to 50°C, meeting usage requirements.

6. Utilizes an efficient and stable electric fusion welding system, making installation convenient and fast, suitable for various complex installation conditions.

Applications of leak-proof double-layer fuel pipes:

Traditional gas stations using metal pipelines are prone to corrosion damage, resulting in gasoline leaks, environmental pollution, and groundwater contamination. With increasing environmental protection requirements, metal pipelines have gradually been replaced by plastic pipelines.

The gas station fuel pipe system features cleaner, safer, sturdier, and faster characteristics, and has been adopted in numerous gas station constructions.

The proportion of polyethylene composite pipes used in gas station fuel pipelines in developed countries like Europe and the United States: 100% in the U.S., nearly 80% in Europe.

Most gas stations in China still use traditional metal pipelines, with about 5000 foreign-funded gas stations using polyethylene composite pipes, showing a significant gap compared to developed countries in Europe and America.

With the increasing domestic environmental protection requirements, Sinopec and PetroChina have begun to widely adopt gas station fuel pipes in new and renovated gas stations.

Leak-proof double-layer fuel pipes for gas stations, Lanzhou double-layer fuel pipes, 75*63 double-layer fuel pipes

Technical parameters of leak-proof double-layer fuel pipes for gas stations:

Characteristics: Gas station double-layer composite pipes are corrosion-resistant, environmentally friendly, anti-permeable, anti-static, impact-resistant, lightweight, easy to connect, and have a long service life.

Model specifications: Double-layer composite pipe—75*63

Single-layer composite pipe—63 75 90 110mm

Application scope: Underground fuel transfer within gas stations

Color: Black

Length: Gas station double-layer composite pipe coils: 50 meters/coil 30 meters/coil

Straight pipes: 6 meters/length

Material: EVOH material

New national standard GB 50156-2012 requirements for leak-proof double-layer fuel pipes for gas stations:

1. When using double-layer non-metallic pipelines, the outer pipe must meet the requirements for oil resistance, corrosion resistance, aging resistance, and system test pressure.

2. The gap between the inner and outer pipes of the underground gas station double-layer fuel pipe system should be open.

3. Leakage detection points should be set at the low points of the underground gas station double-layer fuel pipe system.

4. Leakage detection for underground gas station double-layer fuel pipe systems should preferably use online monitoring systems.

Engineering cases of leak-proof double-layer fuel pipes for gas stations:

1. Gas station fuel pipe renovation project in Gar County, Tibet 2000 meters

2. Gas station renovation project of Dongfang Petroleum Equipment Co., Ltd. in Dingzhou 1000 meters Underground gas station double-layer fuel pipes

3. Gas station renovation project of Jingbiao Petrochemical in Kaifeng 800 meters Underground gas station double-layer fuel pipes

4. Gas station renovation project of Yandong Hongda in Beijing 400 meters

Henan Deyuan Rubber and Plastic Products Co., Ltd. is a high-tech enterprise integrating R&D, production, and sales, specializing in the production of leak-proof double-layer fuel pipes for gas stations, oil well pipes, ultra-high molecular weight polyethylene pipelines, tunnel escape pipelines, steel belt reinforced polyethylene (HDPE) spiral corrugated pipes, HDPE pipes, internally and externally coated composite steel pipes, 3PE anti-corrosion pipes, lined plastic pipelines (steel-lined PO pipes, steel-lined PE pipes, steel-lined fluoropolymer pipelines), lined rubber pipelines and other series of pipes and fittings products of various specifications. The products are mainly used in chemical, electric power, mining, metallurgy, pharmaceuticals, water conservancy, municipal, construction, environmental protection, dredging, coal washing, and other industries.

Surviving by quality, developing by reputation, we sincerely welcome your patronage, and look forward to serving you!