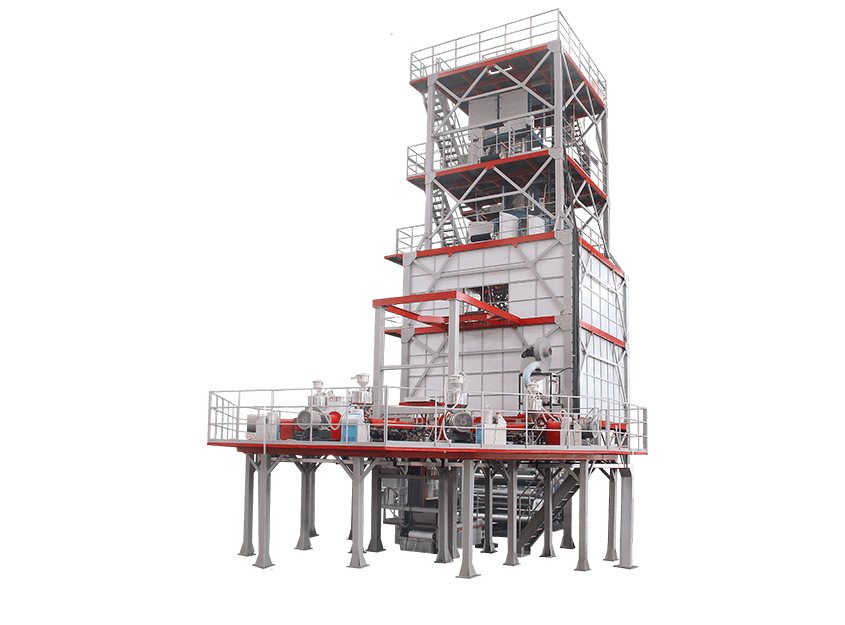

The Jinming ClassicX series blown film line is a mid-to-high-end model that has been optimized from existing machine products, offering customization and high productivity. Based on standard configurations, it can be customized according to the actual production processing needs and process conditions of customers, meeting high-quality production requirements such as film uniformity control, film transparency, film stiffness and toughness, and film output.

Component Introduction

Jinming's counterflow air ring, developed over many years, is an efficient cooling air ring with adjustable multiple air outlets. It controls the outlet temperature at various points through uniformly distributed heating units in the air ducts, effectively regulating the thickness uniformity across the bubble width. Together with the online automatic film thickness measurement system, it forms a closed-loop control system for automatic film thickness control. This significantly improves the quality of film products while enhancing cooling efficiency by up to 30% to 50%. Additionally, this air ring technology changes the traditional method of inflating the bubble immediately after exiting the die. By adjusting the height to pre-cool the bubble before inflation, it allows the polymer material to stretch and set in a semi-viscous state, achieving lower crystallinity, thereby improving film transparency and mechanical properties. It also supports higher blow-up ratios.

Equipped with a satellite flexographic printing press, the printing material can complete multi-color printing in one pass on the impression cylinder, improving print registration accuracy. The short distance between printing stations saves time for color adjustment and reduces material waste during adjustment. An automatic ink circulation system with stirring is used to avoid color differences and improve printing speed.

Equipped with a double-sided internal embossing device for films and a side insertion mechanism for M-shaped edges, the insert board is made of wood and can be manually adjusted from multiple angles to control the insertion depth.

Technical Specifications

| Model | M3B-900Q-C | M5B-900Q-C |

| Layers | 3 | 5 |

| Maximum Product Width | 750mm | 750mm |

| Conventional Product Thickness | 0.03-0.20mm | 0.03-0.20mm |

| Suitable Raw Materials | LDPE, LLDPE, mLLDPE, HDPE, POE, etc. |

LDPE, LLDPE, mLLDPE, HDPE, POE, etc. |

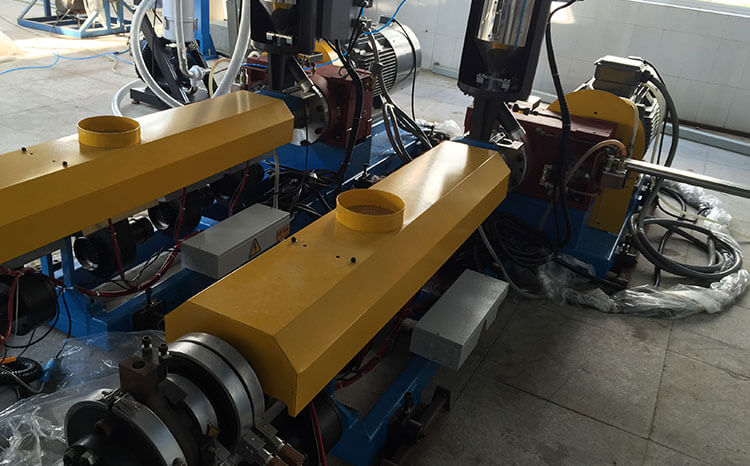

| Screw Diameter | Φ60/80/60mm | Φ60/70/80/70/60mm |

| Maximum Extrusion Rate | 560kg/H | 970kg/H |

| Total Installed Power | 350kw | 600kw |

| Highest Traction Speed | 60m/min | 60m/min |

| Dimensions (L×W×H) | 15×8×17m | 15×10×17m |

In addition to the above models, M3B-1300Q-C and M5B-1300Q-C models are also available.

Application Fields

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others