Features and Applications of Thermal Insulation Sleeves

Weather-resistant, pollution-resistant, and prolongs equipment lifespan

The service life in natural environments can reach decades, maximizing the protection of pipes, cables, and equipment in these settings, greatly extending their lifespan.

Ozone resistance, voltage resistance, arc resistance, and corona resistance

Due to the surface being coated with silicone, which has a main chain of -Si-O-, the bonds are not easily decomposed by ultraviolet light and ozone. The high-temperature protective sleeves possess excellent electrical insulation properties, with dielectric loss, voltage resistance, arc resistance, corona resistance, volume resistivity, and surface resistivity all ranking among the best in insulating materials, and their electrical performance is minimally affected by temperature and frequency. Therefore, they are stable electrical insulating materials widely used in the electronics and electrical industries.

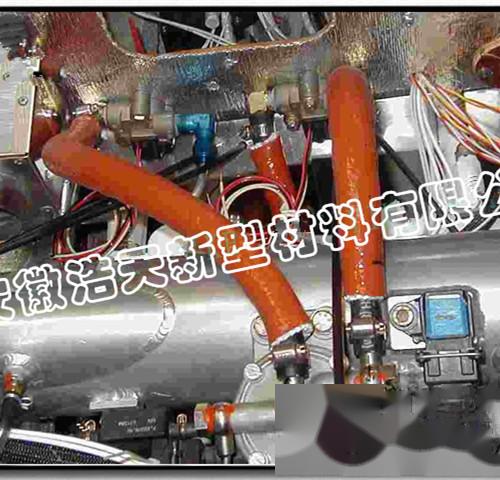

Excellent high-temperature resistance

The high-temperature protective sleeves can withstand continuous exposure to temperatures of 260℃ without damage, and can endure temperatures up to 1090℃ for 15 to 20 minutes, and can withstand 15 to 30 seconds at 1650℃. Its unique flame-retardant properties not only effectively prevent personnel from suffering burns from high-temperature pipelines but also significantly reduce the cost of thermal energy loss.

Unique chemical stability

High-temperature protective sleeves exhibit strong chemical stability, showing no reaction with oils, water, acids, and bases. They can be used long-term at temperatures below 260℃ without aging, and because they are coated with silicone on the surface, they are not easily decomposed by ultraviolet light and ozone.

Splash-proof, multi-layer protection

In the smelting industry, the medium temperature inside electric furnaces is extremely high, easily leading to high-temperature splashes (similarly in the welding industry). Once cooled and solidified, these can form slag on pipes or cables, causing the rubber outer layer of the pipes or cables to harden and eventually become brittle and crack. This can damage unprotected equipment and cables. The high-temperature sleeves, coated with multiple layers of silicone, provide multi-layer safety protection, with a high-temperature resistance of up to 1300 degrees Celsius, effectively blocking splashes of molten iron, molten copper, molten aluminum, and other high-temperature molten materials, preventing damage to surrounding cables and equipment.

Safe and environmentally friendly

Alkali-free glass fiber has high tensile strength, does not wrinkle or break, is resistant to vulcanization, is smoke-free, halogen-free, and non-toxic, is pure oxygen non-flammable, and has good insulation properties. After being cured with silicone, its safety and environmental protection performance is further enhanced, effectively protecting the health of workers and reducing the incidence of occupational diseases. Unlike products made from asbestos, which pose significant hazards to human health and the environment.