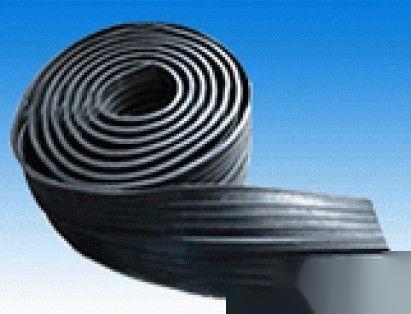

Embedded Rubber Waterstop is one of the main types of Rubber Waterstop, usually also known as embedded Rubber Waterstop or internal embedded Rubber Waterstop, is a type of waterstop that installs the rubber waterstop in concrete deformation joints, expansion joints and other concrete internal settings, with the ability to adapt to concrete expansion and contraction deformations based on the elasticity and structural form of the waterstop material.

Performance Features:

Embedded Rubber Waterstop utilizes the high elasticity and compression deformation characteristics of rubber itself to produce elastic deformation under various loads, effectively securing sealing, preventing water leakage, seepage, and providing damping and buffering effects for building structures.

In many engineering and architectural designs, there are certain requirements for expansion and contraction between civil engineering and geotechnical structures, as well as waterproofing and seismic problems. Therefore, the use and installation of rubber waterstops are effective means to solve the above problems.

Application Range:

Embedded Rubber Waterstop is mainly used in concrete casting during construction joints and deformation joints, becoming an integral part of concrete structures such as foundation engineering, underground facilities, tunnels, culverts, water conveyance aqueducts, and dams, ensuring the service life of construction projects.

Technical Standards:

Embedded Rubber Waterstop is produced in accordance with the national standard GB18173.2-2000 "Polymer Waterproof Material Waterstop". Therefore, we can produce various shapes and sizes of Rubber Waterstop according to customer requirements. In addition, we also have cross-shaped, T-shaped, slope-shaped, and inner and outer corner-shaped products for different engineering projects and locations, which can meet any design requirements.

Construction Method:

Before tying the steel bars, the expansion joint positioning line should be popped out on the cushion layer or lower concrete layer to determine the position of the expansion joint; after the steel bar tying is completed, place the waterstop, fix the two ends of the embedded rubber waterstop with positioning steel bars and flat steel, tighten the two ends of the waterstop with flat steel and weld them to the structural steel bars or positioning steel bars; fix the flat steel with bolts at certain intervals to ensure that the hollow circular ring of the waterstop coincides with the center of the expansion joint, and the two ends of the waterstop should be slightly raised with a 15° to 30° horizontal angle to the hollow circular ring in the middle, making it easier to expel internal air when pouring concrete; for vertically set waterstops, concrete cushion blocks should be tied at certain intervals on the fixed steel bars to keep their interface parts flat; to ensure the center elevation of the horizontal rubber waterstop, control lines should be popped out on the formwork, and steel bars with waterstop rings should be spot-welded at the bottom plate steel bars for elevation checking; generally, the verticality of the vertical rubber waterstop is controlled by hanging a plumb line from the position of the bottom control line.

Before pouring concrete, the Embedded Rubber Waterstop and debris inside the joint should be cleaned, and the waterstop surface should be dried before pouring to ensure a tight bond between the waterstop and concrete; during pouring, horizontal expansion joint construction should be carried out first to ensure concentration of personnel, during pouring and compacting horizontal expansion joint (bottom plate) concrete, there must be someone responsible for tamping and venting near the waterstop, the pouring layer should be slightly higher than the waterstop to facilitate one-time compaction, then use a round wooden stick to tamp each point on the waterstop to expel bubbles underneath; for vertical expansion joints of pool walls, concrete should be poured and compacted on both sides simultaneously in layers, and attention should be paid to adjusting the aggregate gradation to ensure concrete strength and density.