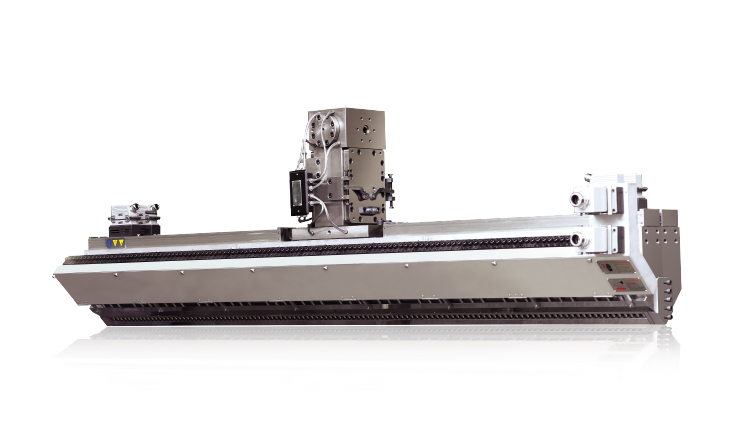

The DYSSJ series shredders benefit from the ingenious combination of a robust pusher and heavy-duty directional bearings, ensuring safe and reliable operation. All DYSSJ models come with a standard push plate, making it easier to crush large solid objects or pallets, wood, etc. The DYSSJ series can be customized with different hopper designs as required. The standard hopper is suitable for bulk feeding using forklifts and manual feeding of large pieces. Hoppers designed for bulk feeding optimize production because the pusher continuously feeds the material to be shredded into the rotor, improving crushing efficiency. The fully automated shredding process prevents overfeeding issues.

Model | Rotor Dia. (mm) | Drive Power (kw) | Rotor Blade (pcs.) | Fixed Blade (pcs.) | Crushing Chamber Size Max (mm) |

|---|---|---|---|---|---|

| DYSSJ-850 | Φ435 | 37 | 60 | 3×2 | 700×730 |

| DYSSJ-1500 | Φ505 | 37 | 102 | 5×2 | 800×1290 |

Note: Informations listed above are for reference only, the production line can be designed by customer’s requirements. Note: The information listed above is for reference only and can be customized according to customer requirements. | |||||

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others