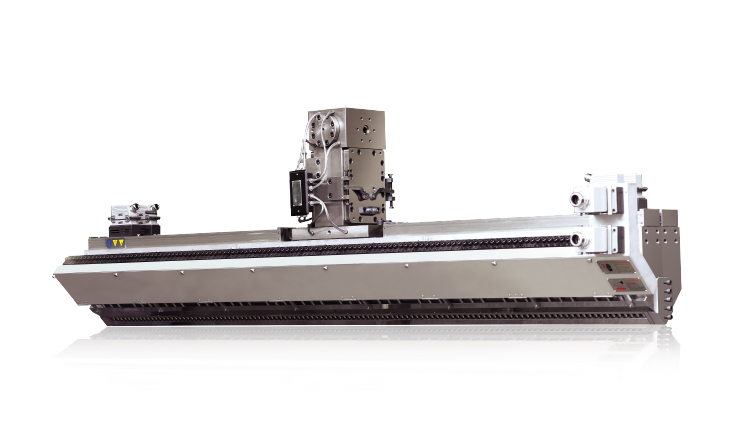

The DYSSG series shredding machine can be used to shred PE, PP, and PVC pipes with a diameter of up to 1600MM. Pipes as long as 3-6M can be directly crushed without the need for segmentation. The machine operates at a slow speed, ensuring smooth operation. Various types of pipes are placed into a horizontal feeding hopper, which automatically closes and uses hydraulic propulsion to push the pipes towards the axis center for crushing. After shredding, the material is transported by a conveyor belt into a crusher for secondary crushing to achieve the desired particle size. The most significant advantage of the DYSSG series shredding system is that it saves a large amount of manual labor and reduces waste from cutting, making it energy-efficient and highly productive. The entire system is controlled by a PLC central control system.

Model | Rotor Dia. (mm) | Drive Power (kw) | Shreddable Pipe Dia. Max. (mm) | Output (kg/h) |

|---|---|---|---|---|

| DYSSG-630 | Φ848 | 2×30 | 630 | 800-1000 |

| DYSSG-800 | Φ1028 | 2×37 | 800 | 1000-1200 |

| DYSSG-1000 | Φ1258 | 2×45 | 1000 | 1200-1500 |

| DYSSG-1200 | Φ1478 | 2×55 | 1200 | 1500-2000 |

| DYSSQ-1600 | Φ1968 | 2×110 | 1600 | 1800-2500 |

Note: Information listed above is for reference only. The production line can be customized according to customer requirements. | ||||

Model | Feed Mouth Size (mm) | Main Motor Power (kw) | Rotor Blade (pcs.) | Fixed Blade (pcs.) | Output (kg/h) | Rotor Dia. (mm) |

|---|---|---|---|---|---|---|

| DYPS-Z 700 | 700×700 | 22 | 6 | 4 | 500 | Φ500 |

| DYPS-Z 800 | 800×800 | 45 | 6 | 4 | 700 | Φ600 |

| DYPS-Z 1000 | 1000×800 | 75 | 10 | 4 | 1000 | Φ700 |

| DYPS-Z 1200 | 1200×1000 | 110 | 14 | 4 | 1500 | Φ800 |

| DYPS-Z 1500 | 1500×1200 | 160 | 18 | 4 | 2000 | Φ1000 |

Note: Information listed above is for reference only. The production line can be customized according to customer requirements. | ||||||

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others