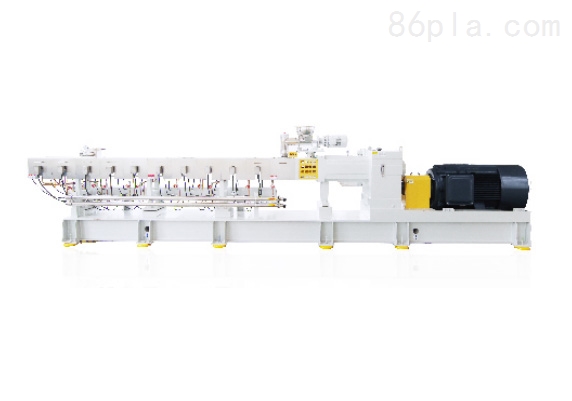

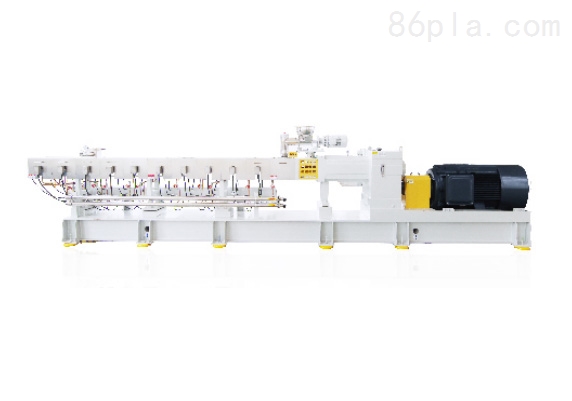

Brief Description:A twin-screw industrial extruder consists of several parts including the drive unit, feeding device, barrel, and screws. The functions of these components are similar to those in a single-screw extruder, as shown in Figure 1. The difference between a twin-screw extruder and a single-screw extruder lies in the fact that the twin-screw extruder has two parallel screws placed within a barrel with an "∞" shaped cross-section.

Features: Equipped with the corresponding screw and auxiliary equipment, it can directly extrude various thermoplastics, especially rigid polyvinyl chloride powder, into pipes, sheets, films, and profiles, and can also complete the modification of various plastics and the granulation process of powders. It uses a DC motor, thyristor infinite speed control, and is equipped with overload protection and fault alarm, screw core oil circulation constant temperature, barrel oil cooling, and is fitted with a vacuum exhaust pipe device and a quantitative feeding device.

Composition

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others