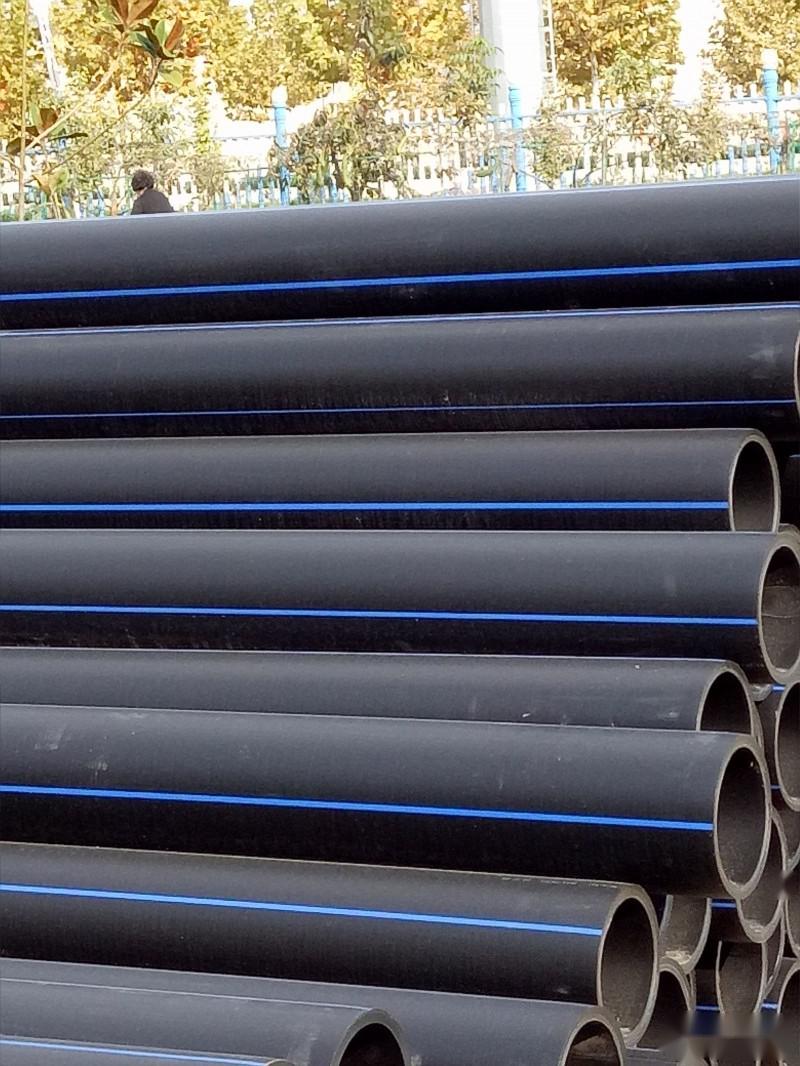

Currently in the Chinese municipal pipe market, plastic pipes are steadily developing, with PE pipes, PP-R pipes, and UPVC pipes all occupying a place, among which the strong development momentum of PE pipes is remarkable. PE pipes have a wide range of applications. The sewage pipe and gas pipe are two major application markets.

PE pipe, the Chinese chemical name for PE is polyethylene, PE material is widely used in the field of water supply and drainage manufacturing due to its high strength, high temperature resistance, corrosion resistance, non-toxicity, wear resistance, etc. Because it does not rust, it is the ideal pipe material to replace ordinary iron water pipes. Therefore, the National Standards Bureau has made a lot of revisions in the new standard GB/T13663-2000, specifying different pressure strengths for PE80 and PE100 corresponding to different levels of water supply pipes, removing the tensile strength performance in the old standard, and adding a fracture elongation rate (greater than 350%), emphasizing basic toughness.

So the question is, both PVC and PE pipes can be used for drainage, which one is better? Today, the editor will lead everyone to see the difference between PVC and PE:

1. The standards of the two are different, the standard for PE water supply pipes is GB/T13663-2000, and the standard for PVC water supply pipes is GB/T10002.1-2006. The requirements for wall thickness and performance indicators for the two are different.

2. PVC has better strength than PE, PE has better toughness (impact resistance) than PVC, and PE can be used at below zero 20 degrees (the internal fluid cannot freeze and remains in a flowing state).

3. PE pipes can be connected by hot melt, with safe, reliable, and high strength connections; PVC pipes are bonded with adhesive or elastic seals, which are convenient and quick.

4. PVC pipe formulations are more complex, with more additives, various additives for drinking water must be safe and non-toxic. PE pipe has fewer additives, generally higher sanitary performance than PVC.

5. PE pipes are more flexible, small-diameter pipes can be coiled, while PVC pipes are harder and cannot be coiled.