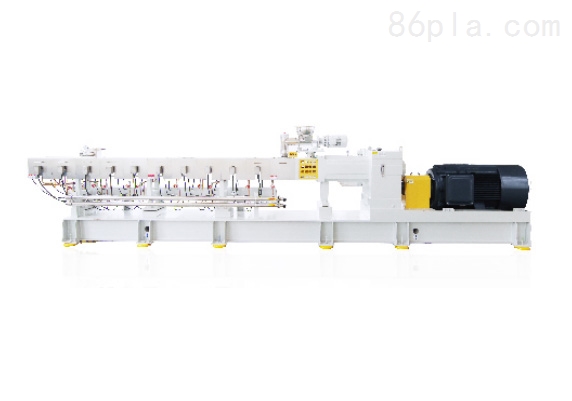

Introduction to Degradable Material Modified Industrial Pelletizing Machine:

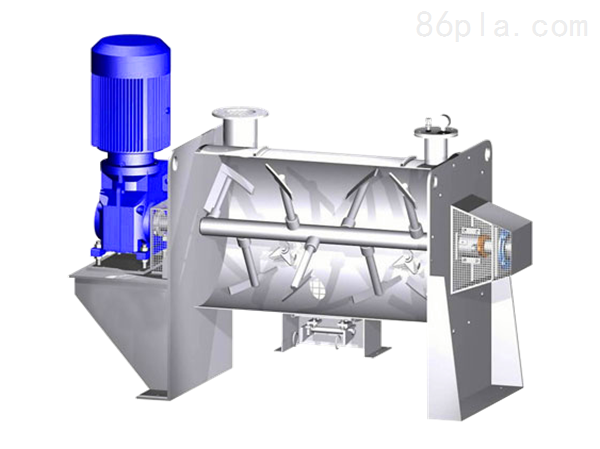

The internal structure of the machine largely depends on its design principles. In other words, technical factors influence its internal structure. The internal structure forms the basis for external appearance, meaning that the external form is a manifestation of the internal structure. This relationship is particularly evident in the design of box-type components.

Apart from the internal structure, there is an inclusive relationship between the internal structure and the external form. Sometimes, the external form itself is a structural design. Since the main work of industrial design focuses on the exterior parts of equipment, the structural and styling design of these exterior parts are closely integrated.

In the degradable material modified pelletizing machine, changes in screw speed are achieved by adjusting the motor speed. Typically, the drive motor runs at approximately 1750 rpm, which is too fast for an extruder screw. If it were to run at such high speeds, excessive frictional heat would be generated, and due to the short residence time of plastic, a uniform and well-mixed melt cannot be prepared. Typical reduction ratios range from 10:1 to 20:1, with the first stage using either gears or pulleys, while the second stage uses gears with the screw positioned at the center of the large gear. For some slower machines, there may be three reduction stages, with maximum speeds as low as 30 rpm or lower (ratio up to 60:1). On the other hand, some long twin-screw mixers can operate at speeds up to 600 rpm or faster, requiring a very low reduction ratio and more intensive cooling.

Precautions:

1. Always pay attention to the temperature changes of the machine body. When touching the strips with clean hands does not stick, immediately increase the temperature until the strips stick normally.

2. If the reducer bearing area feels hot or accompanied by noise, it should be inspected and lubricated promptly.

3. If the bearings at both ends of the main unit's bearing chamber feel hot or produce noise, stop the machine for inspection and add grease. Under normal working conditions, grease should be added every 5-6 days.

4. Pay attention to the operating patterns of the machine; for example, if the machine temperature is too high or low, or the rotational speed is too fast or slow, take appropriate action as needed.

5. If the machine operates unstably, check whether the coupling gap is too tight and adjust it accordingly.

Maintenance of Degradable Material Modified Industrial Pelletizing Machine:

1. Regularly clean oil stains and dust on the motor of the pelletizing machine. If the operating environment is harsh and dusty, it is recommended to clean the motor every few days to ensure smooth operation.

2. Inspect the transmission part couplings for any damage or hard injuries. Damaged couplings can cause many hazards, so they should be replaced promptly to prevent accidents.

3. Check the positions of screws in fixed parts for any loosening. If loose, stop the machine and tighten them immediately to avoid accidents.

4. After a period of use, the bearings of the pelletizing machine should be cleaned and lubricating grease and mechanical oil should be replaced. The frequency of cleaning and replacement should depend on the operating time of the motor, generally replacing the lubricating grease and mechanical oil after about six months of operation.

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others