The price marked online is a reference price, and the specific price will be adjusted and customized according to the material processing requirements and quantity of the physical product.

1. PC Board Cutting

Our company has introduced advanced PC board cutting equipment, ensuring precise and stable cutting dimensions with minimal error. We provide various cutting services for PC solid sheets, PC frosted sheets, PC particle boards, and PC sheets according to customer requirements. The standard specifications for PC boards are 1000mm*2000mm and 1220mm*2440mm, and we can also produce or cut to size as per customer requests.

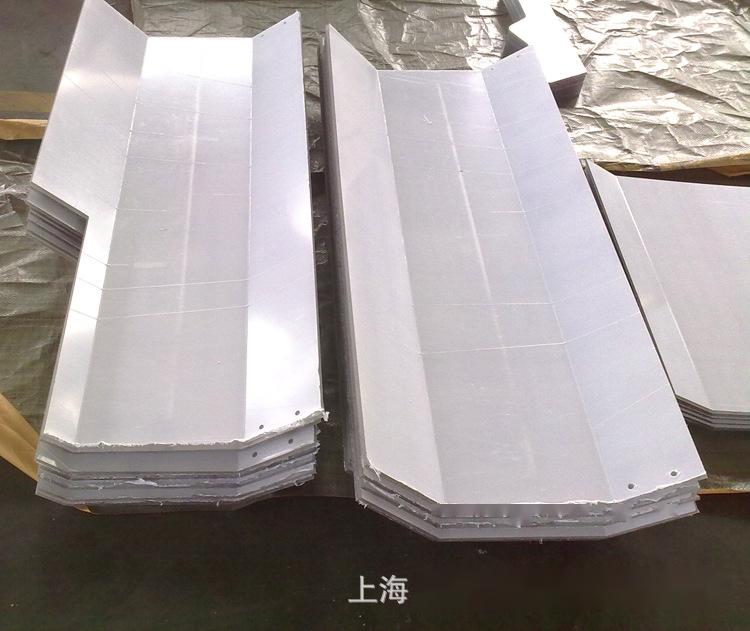

2. Bending of PC Sheets and Boards

The impact resistance of the polycarbonate board can reach 3kg/cm, and the impact strength of PC solid sheets is 250-300 times that of ordinary glass, 20-30 times that of acrylic sheets, and twice that of tempered glass, making it nearly break-resistant. A 3kg hammer dropped from two meters does not leave any cracks, earning it the reputation of "shatterproof glass" and "resounding steel." The impact resistance of PC boards allows for cold bending at room temperature, as well as hot bending. Our company has large bending machines and ovens to perform cold and hot bending forming processes for PC boards within 2.5 meters. The polycarbonate boards can be cold bent on-site according to design drawings to create arched or semi-circular roofs and windows. The minimum bending radius is 100 times the thickness of the board.

3. PC Board Engraving

Using imported PC sheets as the base material, we engrave according to customer-provided drawings or samples. Our company has introduced large CNC engraving machines, with precision controlled within 0.07mm, capable of engraving and cutting various shapes on boards within the size of 1300mm*2500mm, including various flat square holes, round holes, and multi-angle holes, meeting the various processing technical requirements for panels, shells, and windows.

4. PC Board Bonding

Using PC-specific adhesive for bonding PC sheets, ensuring strong, aesthetically pleasing, and glue mark-free results, suitable for making various enclosures, mechanical components, and crafts.

5. PC Board Forming

The physical properties of PC boards, such as impact resistance, heat resistance, cold resistance, and weather resistance, make them widely applicable in automotive parts manufacturing, medical devices, aerospace, electronics, electronic lighting, and other fields. Our company uses imported polycarbonate sheets, with precise mold production, providing processing of PC products in various fields, hot bending forming, maintaining specific dimensions and shapes with an accuracy of over 98%, and timely supply in full compatibility with equipment.

Processing Products

PC electromechanical equipment panels, windows, and enclosures

Our company specializes in the processing of protective enclosures for PC mechanical equipment. We can carry out precise cutting, drilling, bending, hot pressing, and shaping processing of PC sheets according to the technical requirements of customer-specified panels or protective enclosures' CAD drawings or samples, ensuring accuracy of over 98%, full compatibility with equipment, and timely supply.

Applications: Suitable for protective enclosures, panels, windows, and other mechanical shells of electromechanical or mechanical equipment, plastic components, public telephone booths, parking lots, advertising soundproof walls, light boxes, building facades, etc.

Colors: Transparent, Blue, Green, Milky White, Black, Tea Color, Frosted, etc.

Appearance: Various colors, low crystal points, high light transmittance, high smoothness, and good flatness.

Our products are widely used in: landscaping, recreational places for unique decorations and resting areas; interior and exterior decoration of commercial buildings, curtain walls of modern urban buildings; transparent containers in aviation, motorcycle windshields, aircraft, trains, ships, cars, speedboats, submarines, and glass shields for police and military; telephone booths, advertising billboards, light box advertisements, exhibition arrangements; panels for instruments, meters, high and low voltage switch cabinets, and military industry; indoor decorative materials such as walls, ceilings, and screens; soundproof barriers on highways and urban elevated roads; agricultural greenhouses and breeding sheds; greenhouse pavilions, roofs of modern ecological restaurants; bicycle sheds, balcony sunshade and rain shelters, and rooftop resting pavilions within all units or communities; lighting roofs in office buildings, department stores, hotels, villas, schools, hospitals, sports venues, entertainment centers, and public facilities.

The company has a strong customer base nationwide, a high-quality professional team, and a complete sales network, providing products and services for various sheet engineering projects. With modern logistics concepts, we widely serve various industries both domestically and internationally. We will continue to provide sincere service to our customers with excellent quality, outstanding business philosophy, and perfect after-sales service, keeping pace with the times for mutual benefit and harmony!

Pinyi adheres to the corporate tenet of being customer-oriented, winning by reputation, ensuring high quality, and providing excellent service, and aims to win the market through quality and promote development through innovation, providing a complete system of PC sheets for our customers.