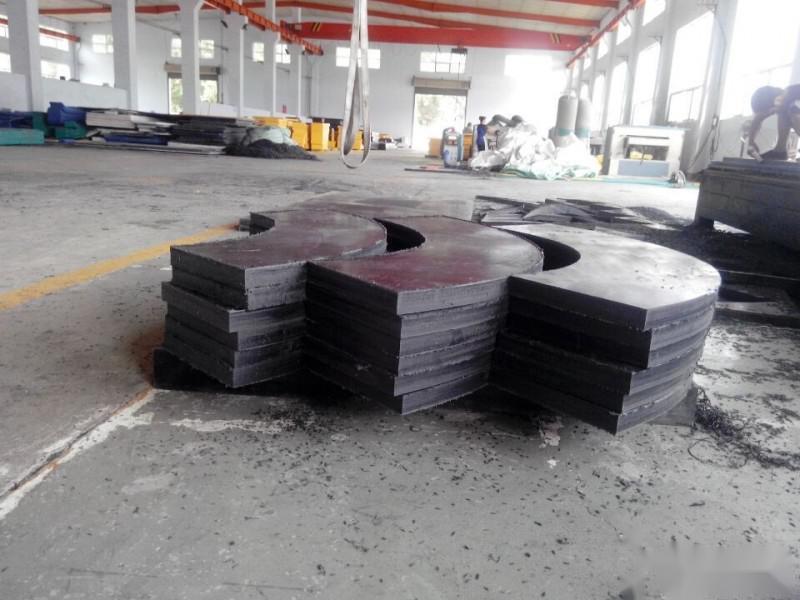

Coal Preparation Plant Arched Screen Wood Made of High Molecular Polyethylene Coal Preparation Plant Arched Screen Wood Made of High Molecular Polyethylene Shandong Ningjin Xinxing Chemical Co., Ltd. specializes in production!!!

Why do large coal preparation plants choose to use ultra-high molecular weight polyethylene boards to produce screen wood? Let Xinxing explain the special properties of ultra-high molecular weight polyethylene:

Why do large coal preparation plants choose to use ultra-high molecular weight polyethylene boards to produce screen wood? Let Xinxing explain the special properties of ultra-high molecular weight polyethylene:

1. The wear resistance of ultra-high molecular weight polyethylene boards is the best among plastics, and the larger the molecular weight, the higher the wear resistance and impact resistance of the material;

4. Extremely low water absorption. Therefore, its physical and mechanical properties are independent of the humidity factors of the working conditions.

Coal Preparation Plant Arched Screen Wood Made of High Molecular Polyethylene Coal Preparation Plant Arched Screen Wood Made of High Molecular Polyethylene

Screen wood is an important component of the safety assurance in coal preparation screen plates, and its performance directly affects work safety. The screen wood made of ultra-high molecular weight polyethylene provides even safer assurance due to its unique properties.

2. The impact strength of ultra-high molecular weight polyethylene boards is one of the highest among existing plastics, and it still maintains considerable impact strength even at 70℃;

3. Self-lubricating, low friction coefficient, energy-saving, and has a wax-like feel.

5. Ultra-high molecular weight polyethylene boards are chemically stable and can resist corrosion from various corrosive media such as acids, bases, salts, and organic solvents within certain temperature and concentration ranges.

6. Ultra-high molecular weight polyethylene boards are odorless, non-toxic, and non-corrosive, with physiological circulation and adaptability.

7. Non-adhesive;

8. When the molecular weight of high-density polyethylene exceeds 500,000, the embrittlement temperature drops to 140℃. Ultra-high molecular weight polyethylene can even be used at temperatures below -269℃ under liquid nitrogen and still retains certain mechanical strength.

With so many special properties, what other practical application areas does ultra-high molecular weight polyethylene have besides being used as sealed screen wood in coal preparation plants?

1. Linings: coal bin liners, material bins, hoppers, wear-resistant plates, brackets, chutes, and other return devices, sliding surfaces, rollers, etc.;

2. Food machinery: guide rails, star wheels, guide gears, rollers, bearing liners, etc.;

3. Papermaking machinery: water absorption tank covers, deflector plates, water scraping plates, water wings;

4. Chemical industry: sealing filling plates, filling materials, vacuum molds, pump components, bearing liners, gears, sealing joints;

5. Conveyor machinery: turntables, guide rails, wear-resistant strips, curved guide rails, magnetic bends, chain guide rails, gears;

6. Others: agricultural machinery, ship parts, electroplating industry, ultra-low temperature machinery components, etc.;

7Large cranes and heavy machinery: placed under the legs of large cranes to support them.

8As port and dock fenders, collision pads, and buffer boards to prevent collisions between ships and docks.

Coal Preparation Plant Arched Screen Wood Made of High Molecular Polyethylene Coal Preparation Plant Arched Screen Wood Made of High Molecular PolyethylenePhone: 0534-5223277 13173333540

Online QQ: 2875013107

Email: xxhgzlz@163.com

Zhang Longzhen from Xinxing Chemical is dedicated to serving you!

Can be processed and produced according to your dimensions.

As long as you provide the drawings, we can process and produce for you.

Color: multiple colors can be processed.

Specifications: custom-made according to customer requirements.

Packaging: waterproof pallets.

Shandong Xinxing sincerely looks forward to cooperating with you!