Activated alumina desiccant is a porous material with adsorption properties and catalytic activity, characterized by high dispersion and a large specific surface area. It is suitable for drying various gases and liquids and is used as an adsorbent, drying agent, catalyst, and carrier in many reaction processes in petroleum, fertilizers, and chemical industries. This product is made from high-purity alumina through scientific formulation and catalytic refinement. It has high compressive strength, long service life, and can be reused multiple times through regeneration methods.

The principle of defluorination is that fluoride ions are adsorbed on the surface of the adsorbent to form insoluble fluorides, while the SO42– on the adsorbent can exchange for other anions such as F- and HCO3ˉ in water. The adsorbent can be placed in a filter bed with a thickness generally ranging from 700 to 1000 mm and a particle size of 0.5 to 2.5 mm, with a filtration rate of 1.5 to 2.5 m/n. The supporting layer is made of gravel, with a thickness of 400 to 700 mm, and the pH of the raw water is adjusted to 5.5 to 6.5 using acid.

Using small particle activated alumina, which has a large specific surface area, can enhance the defluorination effect and reduce water production costs. When the defluorination capacity of the activated alumina adsorbent does not meet the standard, an aluminum solution of 1% to 2% can be prepared and passed through the filter column at a flow rate of 0.6 m/n for 6 to 8 minutes to regenerate it, allowing for repeated use. This method has a strong defluorination capacity and is an excellent technology for removing fluoride and other inorganic ions.

Typically, activated alumina is produced by calcining hydrated alumina at 400℃ to 600℃ or by burning general alumina with alkaline metal ions at 400℃ to 500℃ to form white granular porous adsorbent.

//// Adsorption Function of Activated Alumina Desiccant

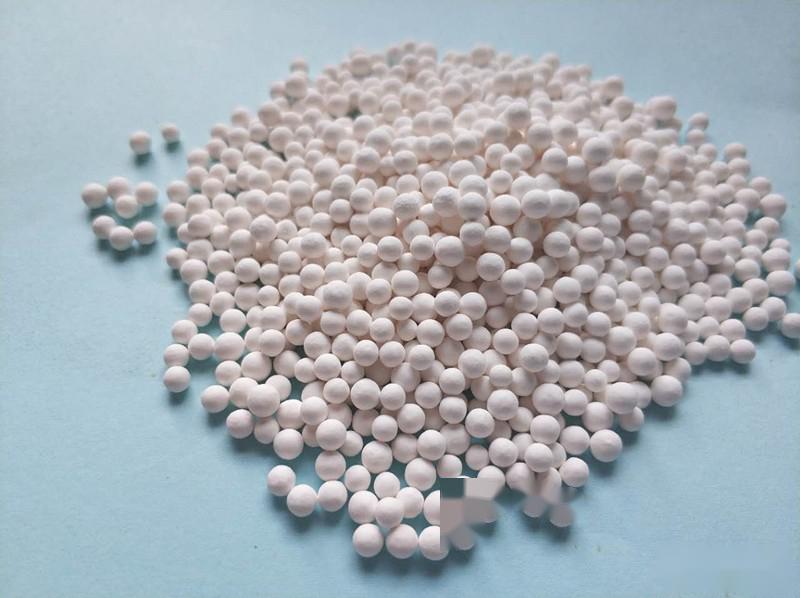

Activated alumina desiccant is a multi-microporous spherical substance with strong adsorption capabilities, a large specific surface area, high compressive hardness, long service life, and can be reused through regeneration methods. This product is a white, spherical porous substance that is non-toxic, odorless, does not powder, and is insoluble in water. It is widely used in industries such as petrochemical, chemical, textile, and metallurgy for instrument air drying, and in pressure swing adsorption air separation devices, with a dew point adsorption capability of over -41 degrees. It can also be used for deep drying of liquid and gas phases in steel, petroleum cracking gas, ethylene, and propylene.

Activated alumina, also known as reactive alumina, has the English name Activated Alumina or Reactive alumina; activated alumin(i)um oxide. When used as a catalyst, alumina is commonly referred to as "activated alumina." It is a porous, highly dispersed solid material with a large surface area. Its microporous surface possesses the characteristics required for catalytic activity, such as adsorption properties, surface activity, and excellent thermal stability, making it widely used as a catalyst and catalyst carrier in chemical reactions. Spherical activated alumina for pressure oil adsorption is a white, spherical porous particle with uniform granule size, smooth surface, high mechanical strength, and strong moisture absorption. It retains its original form without swelling or cracking after absorbing water, is non-toxic, odorless, and insoluble in water. Activated alumina is an efficient drying agent for deep drying of trace water and is particularly suitable for non-thermal regeneration devices.

//// Main Factors Affecting the Adsorption Performance of Activated Alumina:

1. Particle Size: The smaller the particle size, the higher the adsorption capacity; however, smaller particles also have lower strength, which affects their service life.

2. pH of Raw Water: When the pH is greater than 5, a lower pH will result in a higher adsorption capacity of activated alumina. 3. Initial Fluoride Concentration of Raw Water: The higher the initial fluoride concentration, the larger the adsorption capacity.

3. Alkalinity of Raw Water: A high concentration of bicarbonate in raw water will reduce the adsorption capacity.

4. Chloride and Anion Interference. 5. Influence of Arsenic: Activated alumina has an adsorption effect on arsenic in water. The accumulation of arsenic on activated alumina reduces the adsorption capacity for fluoride ions and makes it difficult to elute arsenic ions during regeneration.