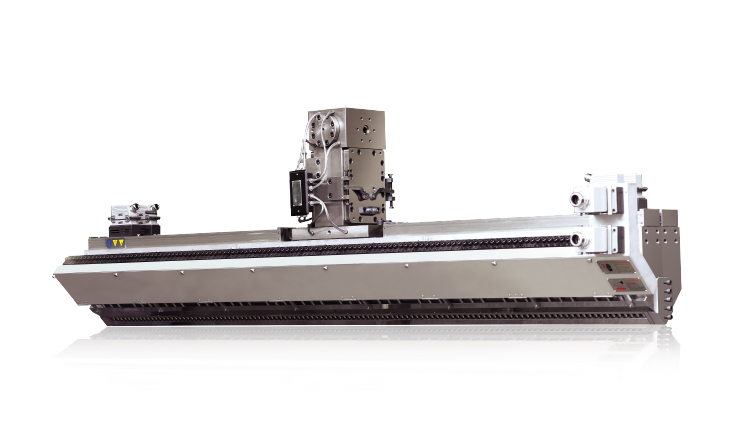

The extrusion die is a critical component in bidirectional stretching equipment, directly determining the shape and thickness uniformity of the cast film. This type of bidirectional stretching cast film die adopts a coat-hanger flow channel design and utilizes professional computational fluid dynamics (CFD) software for flow channel simulation, analysis, and optimization to achieve optimal flow parameters. The die lips feature a push-pull automatic adjustment mechanism, which can automatically fine-tune the lip opening thickness based on thickness data detected by an online thickness gauge and processed by computer programs. This feedback is then applied to special thermal expansion adjustment screws on the die lips, enabling rapid and effective control of product precision. Such dies are suitable for materials like BOPP, BOPS, BOPA, BOPET, BOPI, etc.

The straightness, roughness, and sharpness of the die lips directly impact product quality. Our experiments and validations have shown that localized hardening treatment of the die lips significantly improves die quality. Advantages include higher surface hardness, finer microstructure, superior wear resistance compared to traditional quenching processes, and enhanced straightness and wear resistance after hardening.

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others