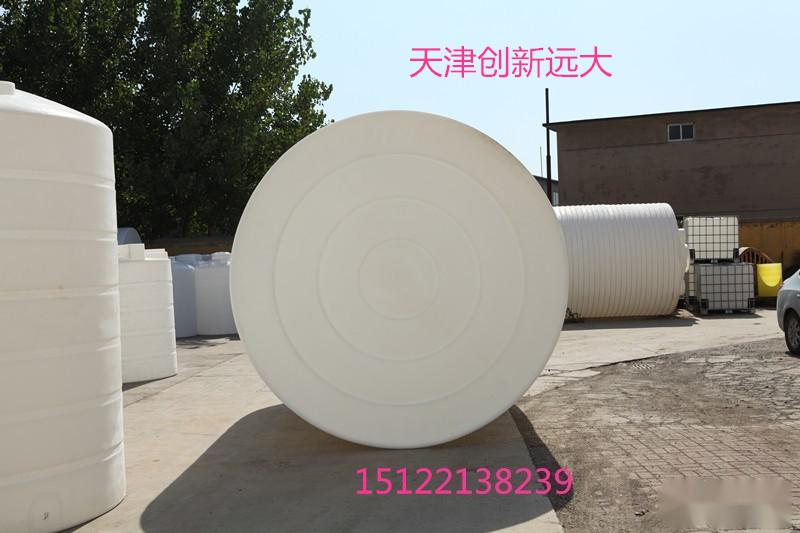

Innovative and Great Plastic Products, Quality Assurance

Material: LLDPE Korean Hyundai Material 644 Low-Density Polyethylene (referred to as PE)

Manufacturing Method: Made using rotational molding technology. It has advantages such as no welding, no leakage, non-toxic, lightweight, anti-aging, impact-resistant, corrosion-resistant, and long service life. The advantages of integral molding, corrosion resistance, and longevity are particularly prominent.

"The principle of survival based on quality and development based on reputation will provide higher corporate services in return for the support and love of friends, and we sincerely welcome your patronage! We look forward to you providing us with product technology and sales information! We hope you will always pay attention to our company and products."

PE All-Plastic Corrosion-Resistant Acid Storage Tank:

1. Due to the excellent performance of linear low-density polyethylene (LLDPE) and the special structure of the rotational molding tank,the service life can last up to 15 years or more.

2. The chemical resistance is very excellent; it can withstand most solutions, except for a few that may cause swelling.

3. The plastic storage tank has anti-corrosion characteristics both inside and outside and can be placed in highly corrosive environments.

4. Rotationally molded anti-corrosion tanks have significant advantages in large specifications, large capacity, and large volume products; despite their large size, they maintain the characteristic of integral molding, which is unattainable by other tank manufacturing processes.

5. Compared with traditional anti-corrosion tanks, they are low-cost with a high performance-to-price ratio.

6. The plastic storage tank features good integral molding, no weld seams, no leakage, strong impact resistance, high tensile strength, good oxidation resistance, and anti-aging properties, meeting sanitary food standards.

7. The softening point of plastic is 108°C, and the fracture point is -70°C, so it can generally be used for

8. When it is uncertain whether a certain substance can be contained, please refer to the "Chemical Performance Table of Polyethylene".

9. The foundation for installing the storage tank must be level and able to withstand the corresponding pressure; if using a steel structure, the gaps must not be too large, and wooden or iron boards should be laid on top.

10. When storing chemical substances, the surrounding area of the storage tank should have a good drainage ditch and dilution device.