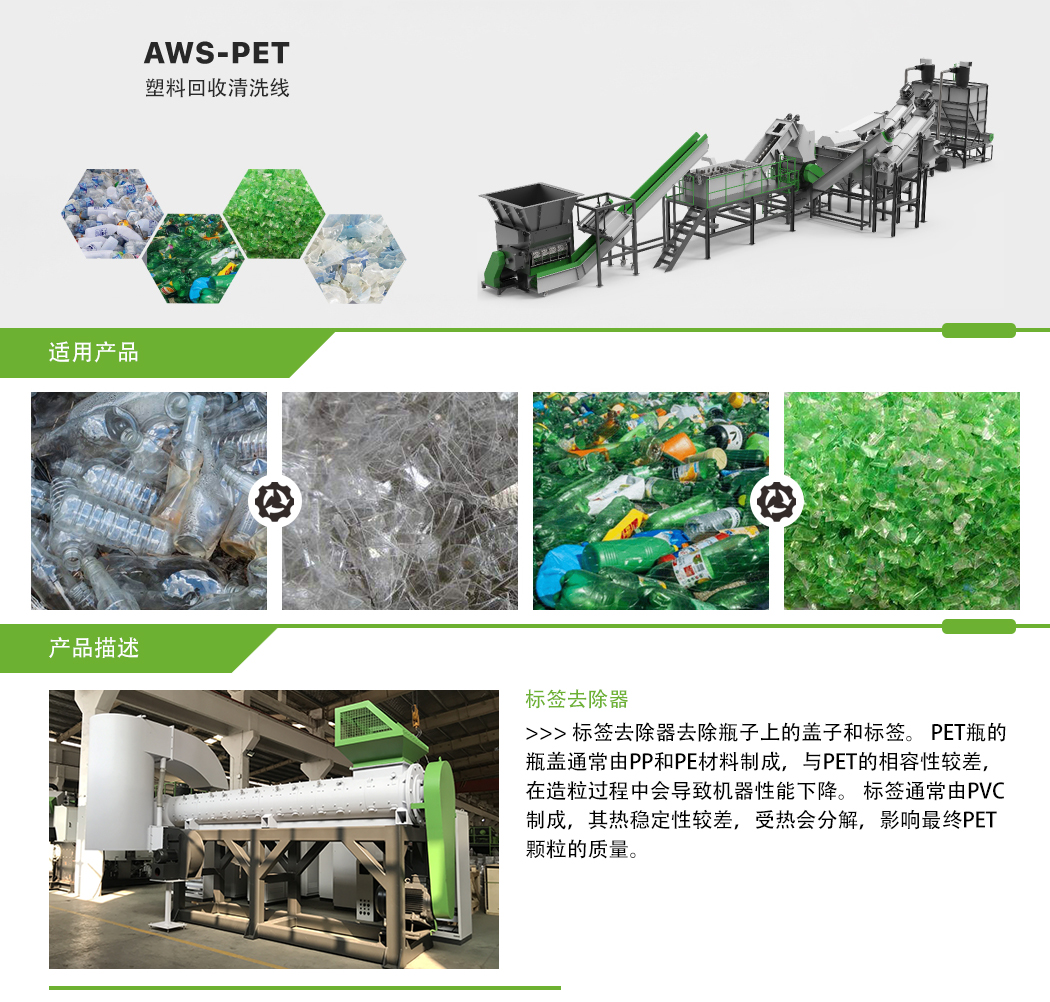

AWS-PET Plastic Recycling Washing Line

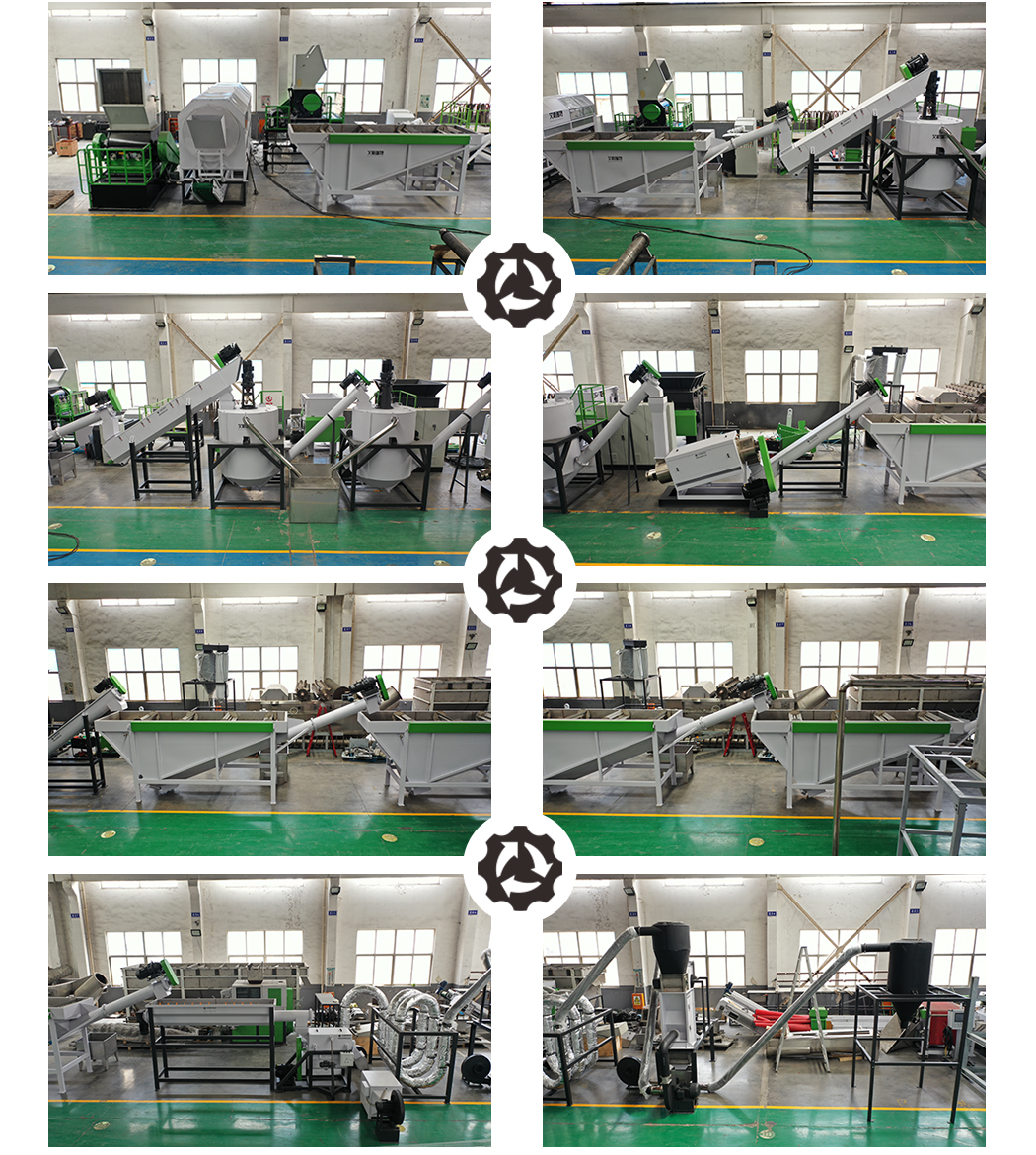

[Product Description]

As is well known, the recycling of PET bottles is one of the most critical aspects of plastic recycling today. ACERETECH has been dedicated to researching PET recycling for many years.

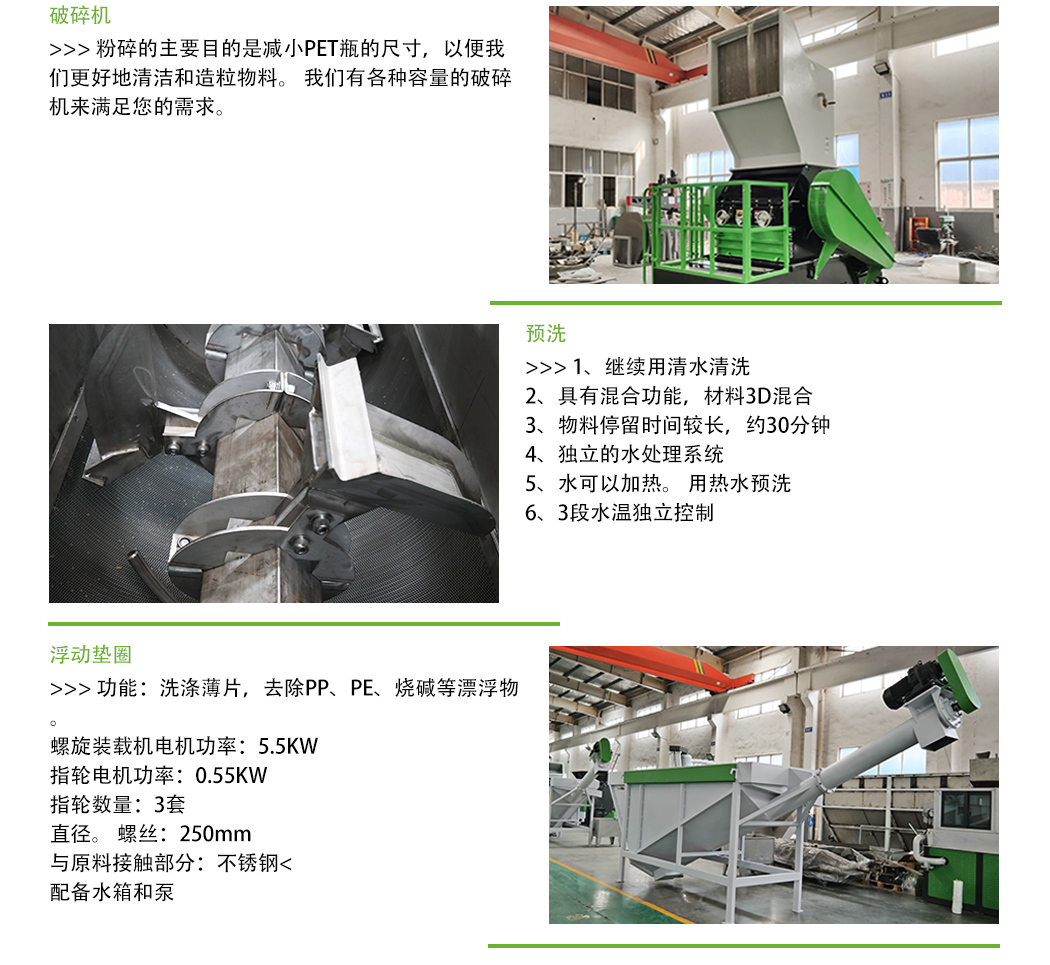

Typically, the process for handling complete PET bottles includes the following steps: sorting → crushing → washing → drying.

PET waste bottles are often very dirty and must undergo rigorous cleaning before granulation to remove contaminants such as oil, dust, and other debris. Additionally, used PET bottles often come with caps, labels, and base supports, which are usually made of PP/PE materials incompatible with PET. Therefore, during the recycling and granulation process of used PET bottles, these components must be sorted separately.

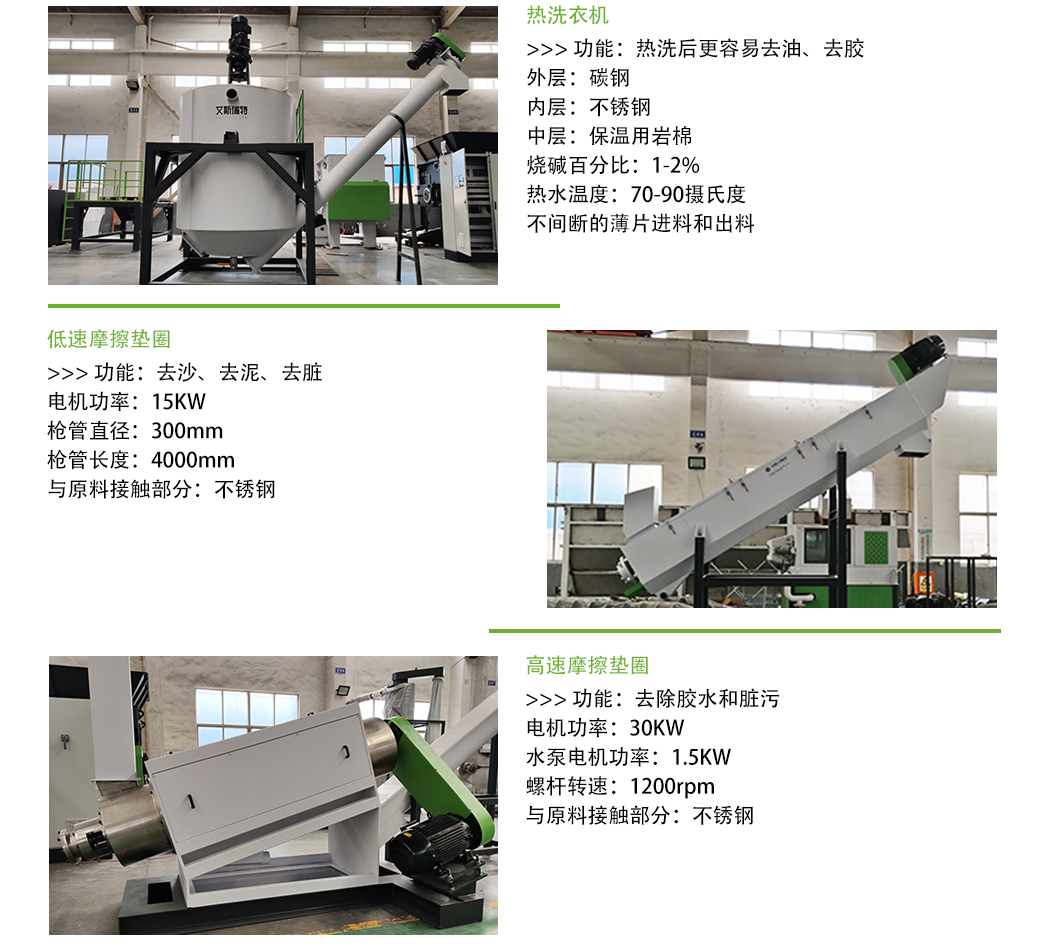

[Product Parameters]

| Device Parameters | |||

| Size | Capacity | Motor Power | Equipment Footprint |

| AWS-PET10 | 1000kg/h | 220KW | 250m² |

| AWS-PET20 | 2000kg/h | 260KW | 350m² |

| AWS-PET30 | 3000kg/h | 380KW | 500m² |

| AWS-PET40 | 4000kg/h | 500KW | 700m² |

| Unit Energy Consumption | |||

| Content | Average energy consumption per ton of bottle | ||

| Electricity | 70-90KW | ||

| Water | 1-1.5T | ||

| Compressed air | 0.5-1m³ | ||

| Steam (optional) | 250-400KG | ||

| Detergent (optional) | 4-8KG | ||

| Bottle Quality Reference | |||

| Description | AA(ppm) | A(ppm) | |

| PVC content | ≤25 | ≤100 | |

| PE/PP/colored bottle/metal/other | ≤75 | ≤100 | |

| Total impurity | ≤100 | ≤200 | |

[Product Details]

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app