ACERETECH ATE Series Co-Rotating Twin-Screw Extruder for Plastic Recycling and Compounding

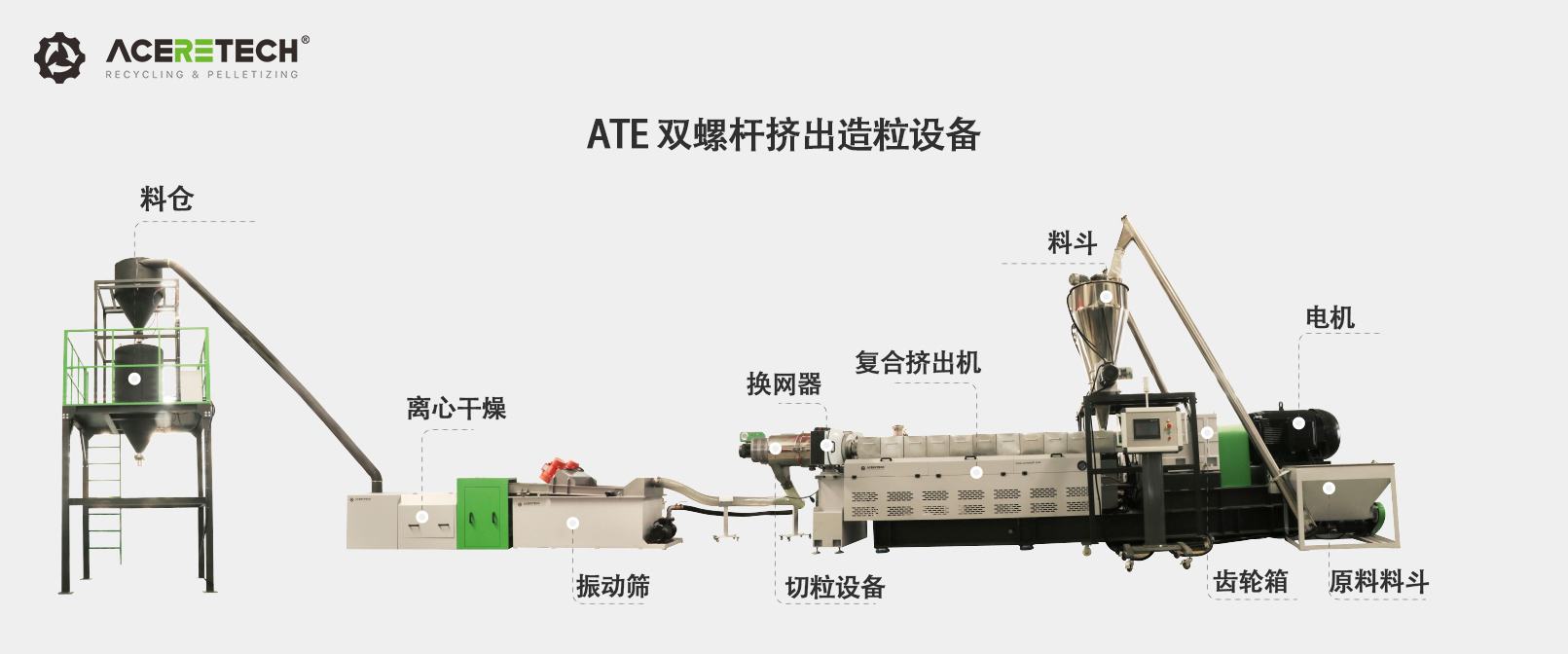

The ACERETECH ATE series co-rotating twin-screw extruder is a professional and reliable system, consisting of a motor drive, torque distribution gearbox, processing section, temperature control unit, die head section, and downstream pelletizing system.

The ATE twin-screw extruder adopts a modular design principle with standardized manufacturing of components, ensuring stable and reliable performance.

Thanks to the modular design, the ATE extruder can provide highly customizable solutions based on customer process requirements and specific needs. Depending on the output torque level, the ATE series extruders are available in basic and efficiency models.

A variety of cutting systems can be combined with the ATE twin-screw extruder, such as strand pelletizing, hot face cutting, and underwater pelletizing.

【Typical Applications】

1. Fiber Reinforcement: Glass fiber, carbon fiber reinforced PP, PA, PBT, ABS, AS, PC, POM, PPS, PET, PPO, PSF, LCP, etc.

2. Polymer Blends: PC+ABS, PA+ABS, CPE+ABS, PP+EPDM, PA+SBS blends, etc.

3. Filler Incorporation: CaCO3, Talc, TiO2, carbon black filled PE, PP, EVA, etc.

4. Cable Compounds: LDPE, HDPE, LLDPE, MDPE cable sheathing and insulation compounds; radiation cross-linked compounds, optical fiber protection compounds, heat shrinkable polymer compounds.

5. Special Compounds: PPR pipe materials, PE cross-linked pipe materials, tobacco filter compounds, etc.

6. High Concentration Color Masterbatches: PE, ABS, PS, EVA, PET, PP, etc., with high concentration pigments and other processing aids.

7. Flame Retardant Masterbatches: PP, PA, ABS, EVA, PBT flame retardant masterbatches, etc.

8. Functional Masterbatches: Anti-static, antibacterial, or other functional masterbatches.

9. Biodegradable Polymer Compounds: High concentration starch and other processing aids blended with PP, PE, PS, etc.

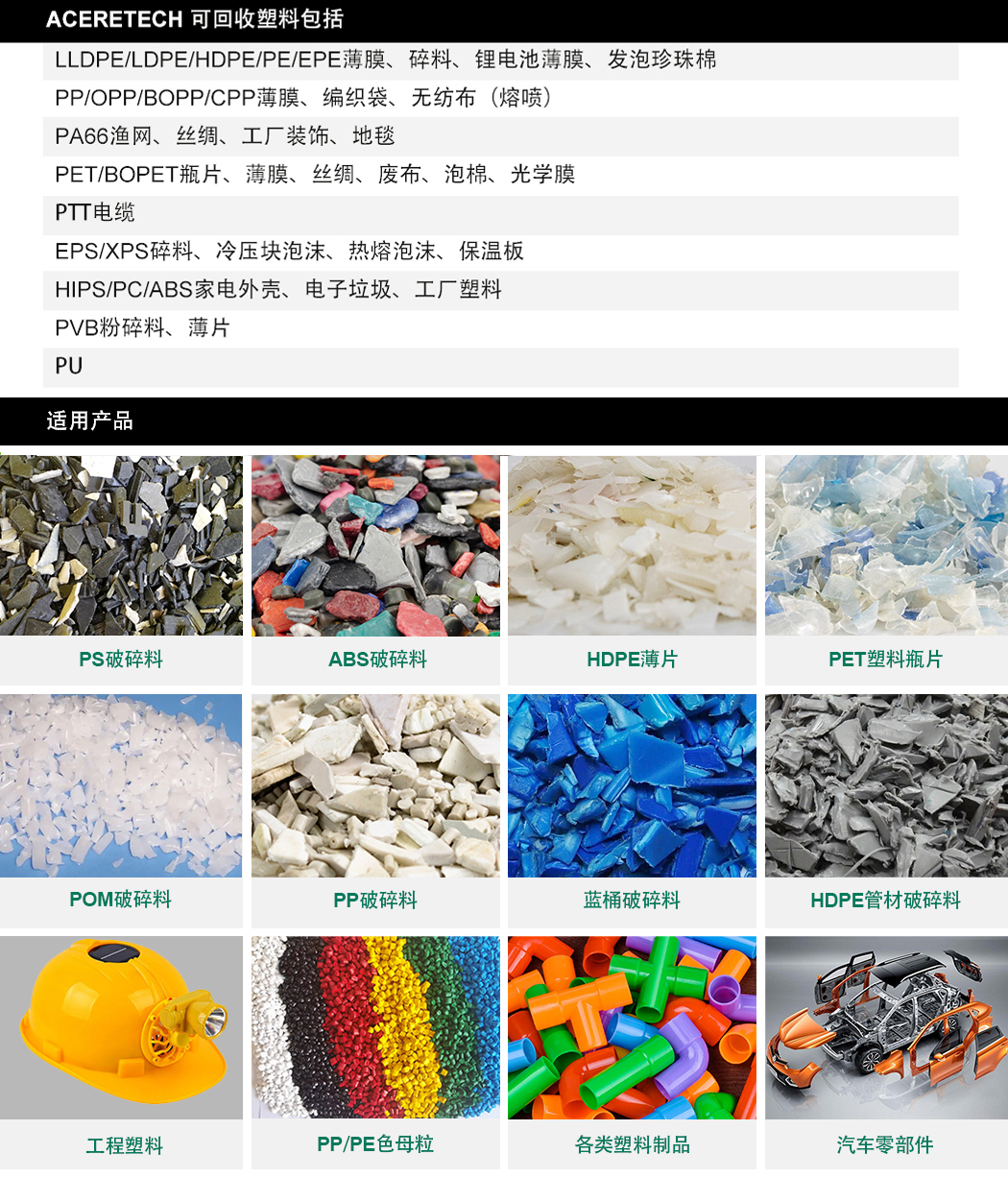

【Applicable Products】

【Manufacturing Process】

【Final Pellets】

【ATE Twin-Screw Extruder Specifications】

| Model | Screw Diameter (mm) | L/D Ratio | Max. Screw Speed (rpm) | Motor Power (kW) | Torque per Shaft (Nm) | Specific Torque T/A3 | Throughput Rate (kg/h) |

| ATE35 | 35.6 | 32-64 | 600 | 18.5 | 115 | 4.2 | 40-80 |

| ATE52 | 51.4 | 32-64 | 600 | 55 | 415 | 5.2 | 150-250 |

| ATE65 | 65.4 | 32-64 | 600 | 90 | 675 | 4.8 | 200-400 |

| ATE75 | 71 | 32-64 | 600 | 132 | 990 | 4.6 | 300-700 |

| ATE95 | 93 | 32-64 | 600 | 315 | 2365 | 5 | 550-1500 |

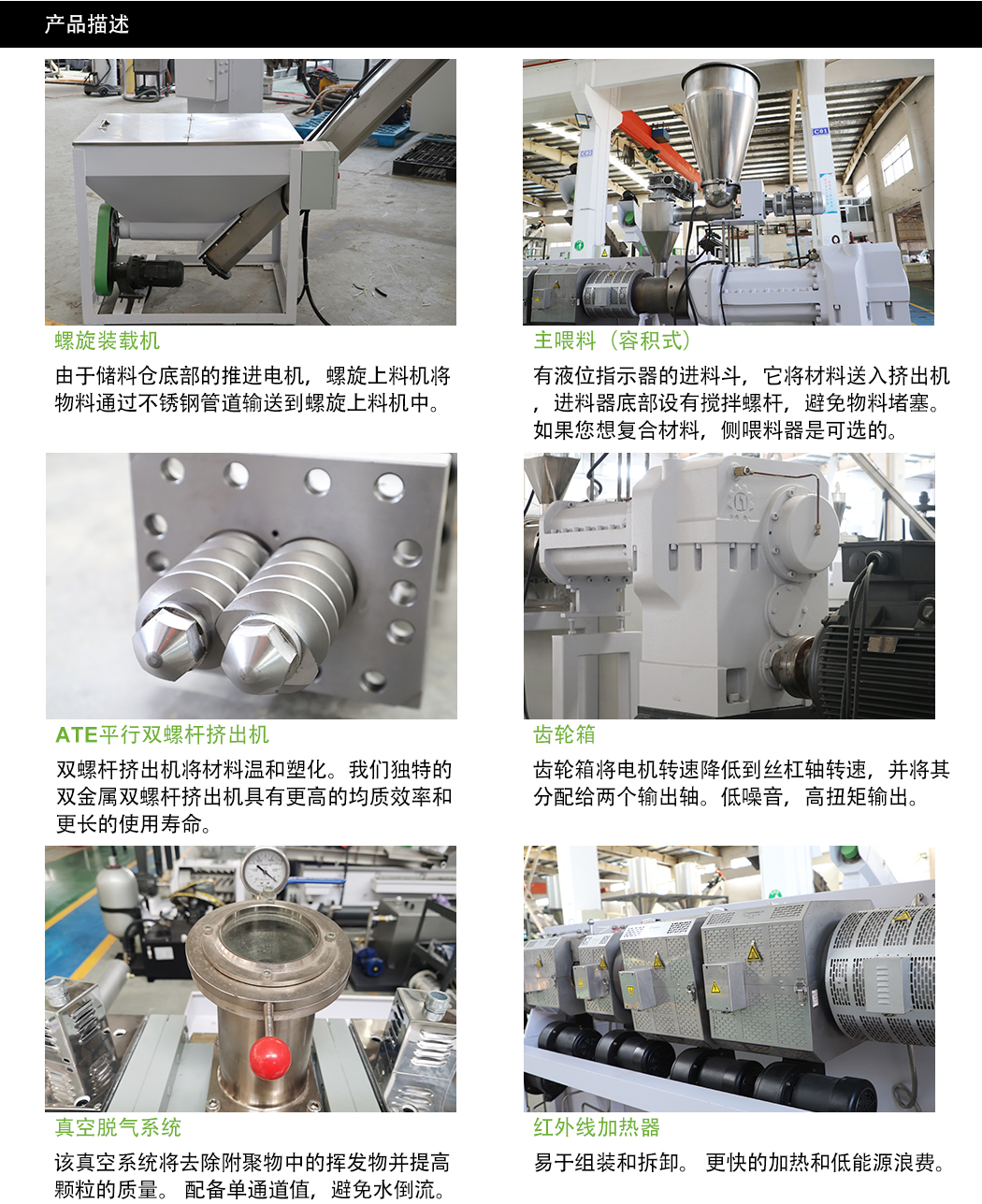

【Product Description】

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app