1. Product Performance

1. The plastic storage tank is formed using rotational molding technology. The softening point of the plastic used is 108℃, and the fracturing point is -70℃, so it can generally be used to store liquids at temperatures from -40℃ to 70℃. If the temperature of the liquid stored exceeds 70℃, a metal reinforcement sleeve should be installed to prevent the tank from softening and deforming. If the tank is used for chemical reactions or dilution, corresponding tests should be done in advance to determine the reaction temperature.

2. Accessories are configured according to the purpose provided by the customer, including PP, PVC, and ABS joints. Options for flanges include PP, PVC, and PE. When storing acidic or alkaline substances, it is necessary to use PVC, PP, or PE accessories and acid-alkali resistant gaskets. For storing organic substances (especially organic solvents), non-soluble rubber gaskets should be used.

3. The company uses imported food-grade PE plastic raw materials for production, with rich production experience in rotational molding products and strict quality control by professional engineering technicians. The containers and various unique and special product shapes produced by the company are aesthetically pleasing, smooth inside and out, non-toxic, odorless, acid-alkali resistant, high-temperature resistant, and freeze-resistant. They are widely used in various industries such as secondary water supply in high-rise buildings, water storage, water treatment, environmental protection, electronics, chemical engineering, pharmaceuticals, food, brewing, vegetable pickling and freezing, greenhouse horticulture irrigation, aquaculture, textile printing and dyeing, and more.

4. The plastic anti-corrosion storage tank refers to the series of seamless plastic (polyethylene) storage and transportation equipment, which is one of the three major series of storage tanks. This series of products is modified with a unique formula to enhance the polyethylene (PE), which has the advantages of no welded seams, no leakage, non-toxicity, lightweight, aging resistance, impact resistance, corrosion resistance, long service life, and compliance with hygiene standards.

5. Other products include: PE food round barrels, food square barrels, biogas tank barrels, turnover boxes, and other plastic container products. The product comes with 2 joints of size 50 and below, and free joint installation. Products can be customized according to customer requirements for openings and processing. Logistics can be arranged for other provinces and cities. The company uses imported food-grade PE plastic raw materials for production, and the rich production experience in rotational molding and strict quality control by professional engineering technicians ensure that products strictly adhere to the quality standards of the People's Republic of China.

2. Installation and Use Instructions

1. The foundation for installing the storage tank must be level and able to withstand the corresponding pressure. If using a steel structure, the gaps should not be too large, and wooden or iron plates should be laid on top.

2. When storing chemical materials in the tank, there should be good drainage ditches and dilution devices around the site.

3. Since the bottom of the tank inevitably protrudes inward during molding, forming a dome shape, the foundation should be made to resemble the dome shape of the bottom (it is recommended to use sand to create a dome shape corresponding to the bottom of the tank on a level foundation).

4. When installing large-scale storage tanks, safety should be a priority; cranes should be used whenever possible. If unsure of the method, please contact us.

5. The plastic joints are tightened at the factory, but they may loosen during transportation and handling. Therefore, before use, the sealing performance of the joints should be checked, and liquid should be added to observe for leaks at the joint. For tanks storing chemical liquids, a water leak test should be conducted first to prevent significant losses.

6. The pipes connected to the joints or flanges at the bottom of the tank must be vertical to the tank wall, and flexible connections should be used whenever possible to avoid damage to the joint and leakage caused by uneven expansion of the tank wall when filled with liquid, which may severely damage the joint and tank body.

7. When the liquid inlet is high above the bottom of the tank, it should bend toward the tank wall to allow the incoming liquid to flow down along the wall, reducing impact on the bottom.

8. For large capacity storage tanks (above 20 cubic meters), metal reinforcement sleeves may be used to limit the expansion deformation of the tank body at the joints, thereby preventing cracking at the holes.

9. When installing heavier auxiliary equipment such as mixers on top of the tank, or when personnel need to work on the tank top that cannot support their weight, please build a separate structure or ladder, and pay attention to safety during operation.

10. When the liquid level cannot be controlled, an overflow port should be installed to prevent liquid from overflowing from the manhole, causing unnecessary harm.

11. When the inflow and outflow rates are large, appropriate vent pipes should be installed.

12. When changing the liquid being stored, please contact our company again.

3. Main Products

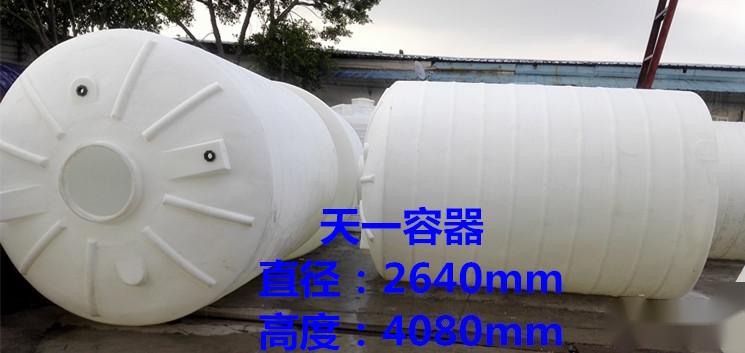

NanNing Tianyi's main products include: PE storage tanks, plastic storage tanks, chemical storage tanks, anti-corrosion storage tanks, plastic water towers, cone-bottom barrels, plastic round barrels, plastic square boxes, dosing boxes, floating boxes, crash barrels, acid washing tank processing, steel-lined plastic products, plastic containers, plastic special-shaped parts welding, transport tank welding, fiberglass waste gas treatment equipment, and large fiberglass containers, and also undertake processing of various special-shaped parts.

3. Company Product Photos