1. This product is manufactured using rotational molding technology, made from imported PE raw materials, resistant to acids and alkalis, corrosion, aging, and capable of withstanding high and low temperatures; from -40 to 80 degrees Celsius. It is widely used in: storage, transportation, and cleaning in food processing; pickling and degreasing in the chemical industry; fermentation, pickling, and storage in the vegetable processing industry; mixing and preparation in pharmaceuticals, food, and chemical industries. The design is aesthetically pleasing, non-toxic, odorless, acid-resistant, alkali-resistant, cold-resistant, not easily aged, easy to install and transport, and is widely used in construction water supply, water treatment, chemical storage and transportation, pharmaceuticals, food, electronics, chemicals, environmental protection, pharmaceuticals, dyeing, dye chemicals, papermaking, power plants, water supply, textile dyeing, and many other industries. Performance: smooth and hygienic inside and outside, molded in one piece, wear-resistant, impact-resistant, with a longer lifespan compared to injection-molded products.

2. Common colors: white, blue, black; Application range: storage, transit, and pickling in hardware, electronics, tools, and parts industries; bleaching, washing, and dyeing in garment, hat, textile, and dyeing industries; fermentation, pickling, and storage in brewing and vegetable processing industries; storage, freezing, and refrigeration in pharmaceuticals, food, and vegetable industries.

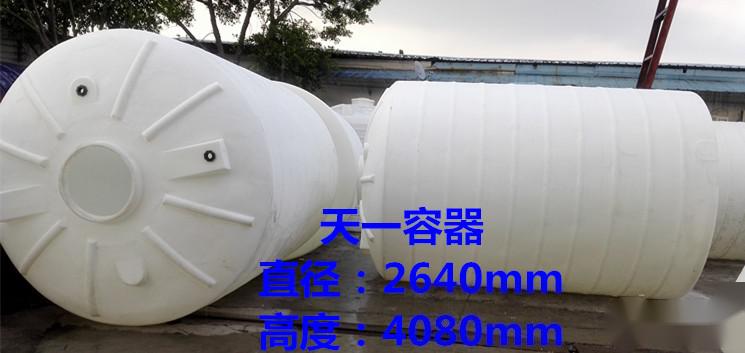

3. Our company focuses on the research and production of plastic products, winning widespread praise in the market with high-quality, cost-effective products and a marketing model based on integrity. All our products are based on technology, using imported PE plastic raw materials, and strictly adhering to quality standards during production. The products have a beautiful appearance, smooth inside and outside, molded in one piece, no welding or seams, non-toxic and odorless, acid-resistant, alkali-resistant, impact-resistant, high temperature (up to 70 degrees), cold-resistant (down to -40 degrees), leak-proof, not easily aged, safe and convenient for installation and transportation, making them ideal plastic containers. Special designs should be communicated in advance. 0.1 tons to 20 tons PE water tanks are widely used in secondary water supply for high-rise buildings, water storage, water treatment, electronics, chemicals, textile dyeing, petroleum chemistry, pickling and electroplating, pharmaceuticals, food, brewing and sugar production, vegetable pickling, aquaculture, freezing, and refrigeration. Our products are distributed across mainland China (all provinces and regions except Tibet), and the lifespan of our water tank products can reach up to 15 years, with advantages such as resistance to scaling, which can replace various products such as steel-lined rubber, plate welding, fiberglass, stainless steel, and clay jars. In the future, our company will adhere to the principle of “survival by quality, development by reputation,” and will repay friends' support and kindness with better corporate service. We sincerely welcome your patronage! We look forward to working hand in hand with you to create more, better, and more special products!

4. Raw materials: LLDPE low-density polyethylene (abbreviated as PE)

Characteristic 1: Acid-resistant and alkali-resistant; please refer to the polyethylene chemical resistance table for details:

(1) If this container is filled with liquids with a specific gravity of 1 or below (weak acids, weak alkalis, and water), the general service life is over 5 years. If placed in a location avoiding sunlight and rain, the service life can be greatly extended.

(2) If filled with acidic or alkaline liquids with a specific gravity between 1-1.2, the aging period is 4-5 years.

(3) If filled with acidic or alkaline liquids with a specific gravity between 1.2-1.4, the aging period is 3 years.

(4) If filled with acidic or alkaline liquids with a specific gravity above 1.4, the aging period is 2 years.

Characteristic 2: The temperature resistance does not exceed 70-80 degrees Celsius, and the cold resistance should not be lower than -30 degrees Celsius.

Characteristic 3: This product is designed for normal pressure and should not be subjected to positive or negative pressure exceeding normal atmospheric pressure (1 atmosphere); if stirring or if the acid or base concentration is above 1.2, it is advisable to install reinforcement sleeves and increase the thickness of the barrel wall. This characteristic is especially important for containers with a capacity exceeding 10000L. (For nitric acid concentrations exceeding 28%, special-grade products must be used and reinforcement sleeves installed.)

Characteristic 4: This container is a one-piece rotationally molded product, featuring advantages of being seamless, non-toxic, odorless, easy to clean, and flexible in handling.

5. Notes: Instructions for interfaces, piping, and reinforcement sleeves

(1) The interfaces or flanges installed before the container leaves the factory may loosen or even be damaged during transportation. It is essential to check for integrity before receiving and installing.

(2) For connections between containers or external pipelines, flexible or U-shaped connections should be used, supported by brackets. No stress should be applied to the pipes and interfaces to prevent damage to the interfaces and the container body due to pressure and weight when the container is filled with liquid.

(3) After the installation of interfaces and pipelines, it is necessary to perform a water test to check for leaks in the container body and the connections.

(4) The interfaces and piping should be checked monthly, and any abnormal situation should be repaired promptly.

(5) Our reinforcement sleeves are made of 250mm, 1.0mm cold-rolled steel plates; installation should be done when the container is not filled with liquid, with tightness adjusted so that it does not fall off the container body. The paint surface of the reinforcement sleeve may be damaged during long-distance transport and handling; therefore, it must be repainted after installation to extend its service life, and grease should be applied to the tightening screws and nuts to prevent rust and maintain strength.

6. Main products: Nanning Tianyi’s main products include: PE storage tanks, plastic storage tanks, chemical storage tanks, anti-corrosion storage tanks, plastic water towers, cone-bottom barrels, plastic round barrels, plastic square boxes, dosing boxes, floating tanks, crash barrels, water barriers, pickling tank processing, steel-lined plastic products, plastic containers, plastic special-shaped parts welding, transport tank welding, fiberglass waste gas treatment equipment, and large fiberglass containers, and we also undertake processing of various special-shaped parts.