1. Product Performance

1. The PE plastic tank is formed using rotational molding technology.

2. The plastic tank produced by the company is made of imported rotational molding materials—Linear Low-Density Polyethylene (LLDPE) or Linear Medium-Density Polyethylene (LMDPE). It can hold most inorganic acids, bases, salts, and many organic substances at room temperature.

3. The softening point of the plastic used is 108°C, and the breaking point is -70°C, so it is generally suitable for holding liquids with temperatures ranging from -40°C to 70°C. If the liquid temperature exceeds 70°C, a metal reinforcement sleeve should be installed to prevent the tank from softening and deforming. If the tank is used for chemical reactions or dilutions, appropriate tests should be conducted in advance to determine the reaction or dilution temperature.

4. Accessories are configured according to the customer's provided use, including PP, PVC, and ABS joints, as well as PP, PVC, and PE flanges. When holding acidic or alkaline substances, PVC, PP, or PE accessories and acid-alkali resistant gaskets should be used. When holding organic substances (especially organic solvents), gaskets that are not easily dissolved should be configured.

5. This product is not suitable for holding strong oxidizers (such as concentrated nitric acid with a concentration of over 50% at a temperature of 60°C, and concentrated sulfuric acid over 30%) and good organic solvents (such as cyclohexanone, formaldehyde).

6. Other products include: PE food round barrels, food square barrels, biogas pond tanks, turnover boxes, and other plastic container products. The product comes with 2 joints of size 50 and below, and free installation of joints. Products can be customized according to customer requirements for openings and processing. Transportation can be arranged for provinces and cities outside the local area. The company uses imported food-grade PE plastic raw materials for production, with rich production experience in rotational molding products and stringent quality control by professional engineering technicians.

7. The company specializes in the production of large various plastic containers, with complete processes and one-time molding. Products include PE tanks, chemical water storage tanks, mixing barrels, transport tanks, round barrels, square boxes, and PE custom processing services.

8. Nanning Tianyi specializes in the production of large and complex-shaped plastic products, integrated with research, development, production, sales, and service as a private technology enterprise.

9. If you are unsure whether a certain substance can be stored, please consult our company in a timely manner or refer to the website.

2. Installation and Usage Instructions

1. The foundation for installing the tank should be level and able to withstand the corresponding pressure. If using a steel structure, the gaps should not be too large, and wooden or iron boards should be placed on top.

2. When storing chemical substances, there should be good drainage ditches and dilution devices around the site.

3. Since the tank inevitably forms a dome at the bottom during molding, the foundation should be made in a similar dome shape (it is recommended to use sand to create a corresponding dome shape on a level foundation).

4. Pay attention to safety when installing large tanks. Use a crane whenever possible. If unsure about the method, please contact us.

5. Plastic joints are tightened when leaving the factory, but they may loosen during transportation and unloading. Therefore, before use, check the sealing performance of the joints. You can fill liquids above the joint area to check for leaks. For tanks holding chemical liquids, first test for leaks with water to prevent significant losses.

6. Pipes connected to joints or flanges at the bottom of the tank should be perpendicular to the tank wall. Use flexible connections to avoid damage to the joints and leaks due to uneven expansion of the tank wall after being filled with liquid, which may lead to serious damage.

7. When the inlet is higher from the bottom of the tank, the inlet should bend toward the tank wall to allow the incoming liquid to flow down along the wall, reducing impact on the bottom.

8. For large capacity tanks (over 20 cubic meters), metal reinforcement sleeves can be used to limit the expansion deformation of the tank body at the joints, thus preventing cracking at the hole.

9. When installing heavier auxiliary equipment such as mixers on the tank, or if someone needs to work on the tank top that cannot support a person's weight, please build a separate frame or ladder, and pay attention to safety during operations.

10. In situations where the liquid level cannot be controlled, an overflow port should be installed to prevent liquid from spilling out of the manhole, causing unnecessary harm.

11. When the inflow and outflow rates are large, appropriate exhaust pipes should be installed.

12. When switching the liquid being stored, please contact our company again.

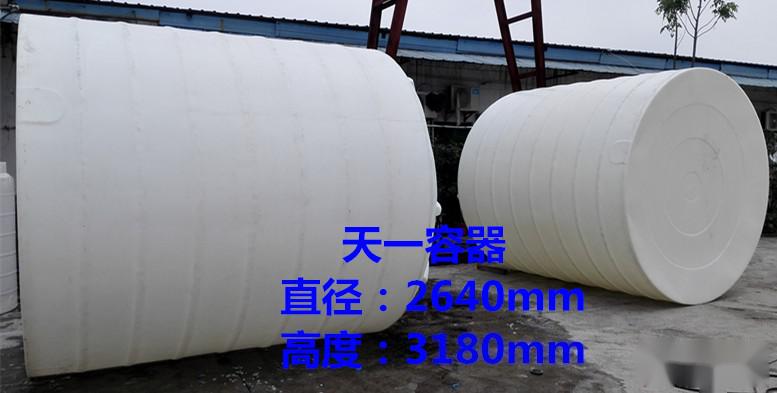

3. Main Products

Nanning Tianyi's main products include: PE tanks, plastic storage tanks, chemical storage tanks, anti-corrosion tanks, plastic water towers, conical bottom barrels, plastic round barrels, plastic square boxes, dosing boxes, floating boxes, crash barrels, acid washing tank processing, steel-lined plastic products, plastic containers, PP plate welding, transport tank welding, fiberglass waste gas treatment equipment, and large fiberglass containers, and also undertake processing of various custom parts.