Waste plastic pyrolysis company completes $50 million in financing!

Recently, the US waste plastic pyrolysis company Freepoint Eco-Systems announced that its plastic waste recycling facility in Hebron, Ohio, has completed a $50 million non-recourse project financing. The term loan was underwritten by ING Capital LLC (“ING”) and is the first of its kind for hard-to-recycle plastics in the plastic recycling sector.

Freepoint's Hebron plant project broke ground in December 2022, initially planned to start in 2024. The company said that the plant, covering 25 acres and utilizing an existing 260,000 square foot warehouse, is planned to have a capacity of processing 90,000 tons of waste plastic annually.

It is worth mentioning that in May 2024, Dow and Freepoint Eco-Systems announced a supply agreement to convert plastic waste into new circular products.

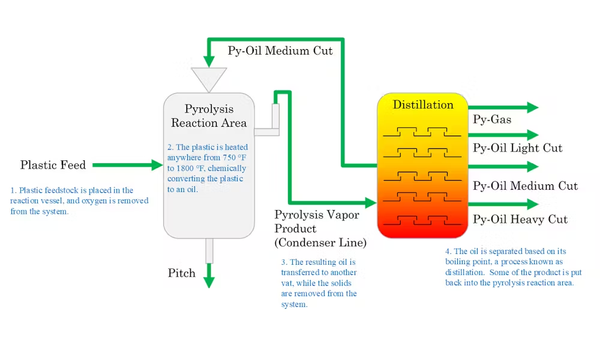

Plastic pyrolysis is a chemical process in which plastic is heated to extremely high temperatures under oxygen-free conditions, chemically decomposing the plastic into other molecules. The main types of plastics processed include post-consumer plastics such as plastic bags, bottles, milk jugs, packaging materials, wet wipes, and even discarded children's toys. Additionally, it can also process tires and electronic products.

It is worth mentioning that polyvinyl chloride (used in pipes and roofing products) and polystyrene (used in packaging) are often avoided or reduced by recyclers in pyrolysis because these plastics produce harmful by-products during the pyrolysis process, making them one of the most difficult waste plastics to chemically recycle.

Charcoal is the solid residue left at the end of the pyrolysis process. It can be used as a carbon-rich material for various purposes, including adding it to the soil to make it more suitable for cultivation, as it can increase soil moisture and pH, which is beneficial for nutrient absorption. Charcoal also has the ability to absorb harmful carbon gases from the air, which helps prevent climate change. However, the main disadvantage of charcoal is that if used in excess, it can increase soil alkalinity, thereby hindering plant growth.

pyrolysis process

Image source: the internet

Currently, about 15% to 20% of pyrolysis products are recycled into new propylene and ethylene, while the majority (about 80% to 85%) is converted into diesel, hydrogen, methane, and other chemicals.

Although plastic pyrolysis has certain prospects, it also faces challenges. The cost of establishing and operating a pyrolysis plant is very high. The profitability of the process depends on the availability of suitable plastic waste, the market demand for the produced oil and gas, as well as the energy and personnel costs required to operate the reactor.

Another issue is quality control. Most types of plastics can be pyrolyzed, but the oils produced from different plastics have different chemical compositions. After pyrolysis, it is necessary to understand the composition of these oils before determining which types of plastics to focus on and how each oil can generate new materials.

However, as more research is conducted on the efficiency of this technology and technological advancements expand the scale of pyrolysis, this technology may become part of a sustainable solution for future plastic waste management.

pyrolysis oil

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track