Wang Lei from Westlake University: One-Step Complete Depolymerization of C-Lignin and G/S-Type Lignin in the Seed Shells of Euphorbiaceae

Given climate change and the depletion of oil resources, researchers urgently need to explore sustainable alternatives to replace non-renewable fossil refining products. For this purpose, inedible plant biomass and other green carbon resources are considered the most promising and abundant renewable resources, which are expected to support economically viable biorefinery processes without having a negative impact on the environment. Lignin, as the main component of lignocellulosic biomass, is the most abundant renewable aromatic biopolymer on Earth. During the depolymerization of lignin, ether bonds such as β-O-4, α-O-4, 4-O-5 are broken, producing lignin-derived monomers that can serve as precursors for direct substitute fuels and high-quality phenolic chemicals. However, the structure of conventional lignin (typically composed of G/S/H-type lignin) is complex and diverse, often intertwined, leading to multiple product streams after depolymerization.

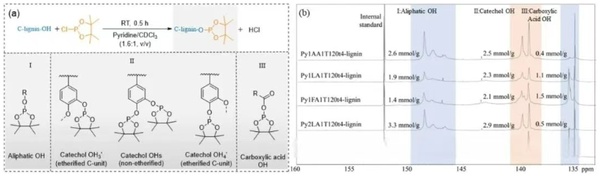

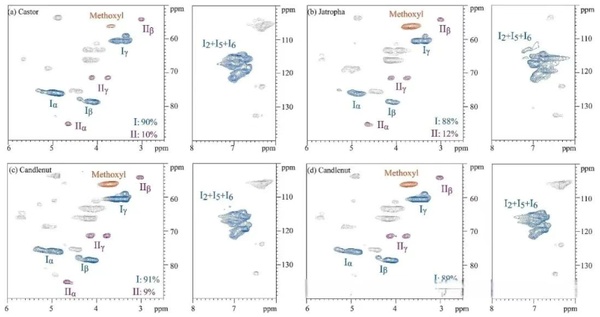

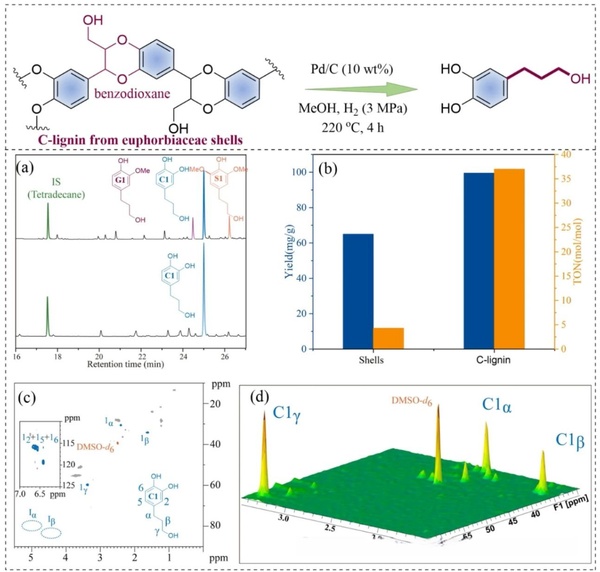

Methoxyl-free catechol-type lignin (C-lignin) is a linear aromatic macromolecule composed solely of catechol alcohol units. Some researchers have pointed out that C-lignin is an acid-resistant and structurally uniform polymer, formed through the oxidative radical polymerization of catechol alcohols in the fruit shells of vanilla, some cactus species, and Euphorbiaceae plants. Therefore, it is considered an ideal prototype for the value-added utilization of lignin. Due to its unique characteristics, C-lignin is regarded as a preferred raw material for producing high-quality catechol or manufacturing advanced materials. For example, some researchers have indicated that by using metal catalysts such as Ru/C, Pd/C, Pt/C, Cu-PMO, Ni/C, and Ru/ZnO/C, the depolymerization of C-lignin isolated from vanilla and Euphorbiaceae fruit shells can be catalyzed to produce catechol derivatives with terminal structures; there are also studies that use extracted C-lignin to prepare carbon fibers through electrospinning technology.

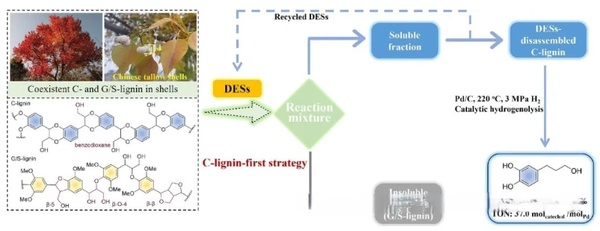

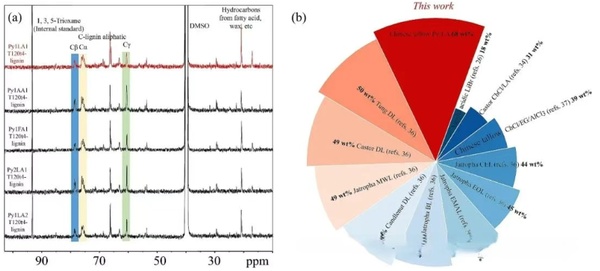

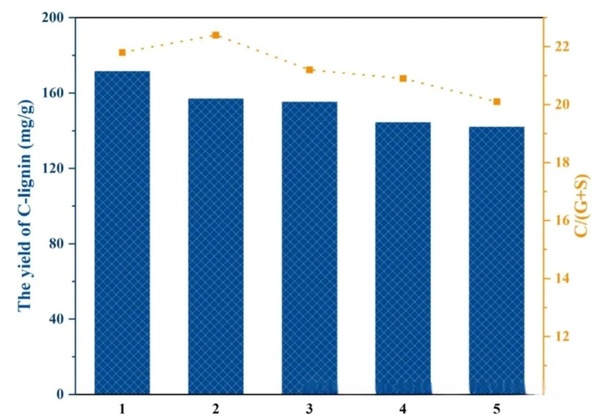

Recently, the characteristic that lignin in vanilla seeds is entirely composed of catechol alcohols has attracted widespread attention and been extensively studied for the value-added utilization of C-lignin. Although vanilla has the potential as a raw material for C-lignin, its low annual production (about 8,000 tons) and high cost (350-500 USD per kilogram) limit its wide application on an industrial scale. Some researchers have pointed out that C-lignin also exists in the fruit shells of Euphorbiaceae materials (such as Chinese tallow tree, castor, Java creeper, wax gourd, and tung oil tree). These Euphorbiaceae fruit shells, as abundant by-products in biodiesel waste, are inexpensive and show great potential for producing catechol chemicals. However, in these seed shells, G/S-type lignin coexists with C-lignin and is produced through independent biosynthetic pathways, which means that multiple product streams will be generated during the catalytic conversion process. Therefore, how to effectively separate the coexisting C-lignin from G/S-type lignin in Euphorbiaceae fruit shells becomes a key step in achieving high yield and high selectivity in the production of catechol.

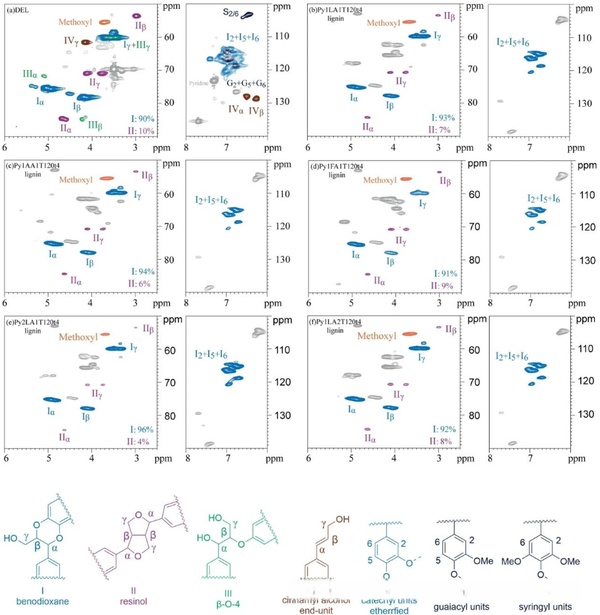

Currently, several "C-lignin first" strategies have been developed, including the use of organic solvents and choline chloride-based deep eutectic solvents, to depolymerize C-lignin before extracting G/S-type lignin. However, researchers have pointed out that these technologies have not yet fully overcome the aforementioned issues. For example, some researchers used a dilute acid/organic solvent approach to depolymerize coexisting C-lignin and G/S-type lignin in Euphorbiaceae fruit shells, and although the yield of C units could reach about 50 wt%, the use of carcinogenic 1,4-dioxane solvent became a major drawback. To replace this toxic solvent, other scholars have explored choline chloride-based deep eutectic solvent extraction methods, such as using a choline chloride/lactic acid deep eutectic solvent for extraction from castor fruit shells, where the C-lignin yield was only about 31 wt%. However, these depolymerization methods usually require complex and expensive separation and purification steps. Recent studies have also shown that N-heterocyclic-based deep eutectic solvents can simultaneously achieve the separation of cellulose, hemicellulose, and lignin, and improve the yield and purity of the obtained G/S/H-type lignin. Due to the electron-donating or -splitting effect of N-heterocycles and their unique interactions with lignin (which has higher electron density than cellulose and hemicellulose), combined with stronger hydrogen bonding with catechol in C-lignin, some researchers speculate that N-heterocyclic-based deep eutectic solvents may more effectively dissolve C-lignin.

Therefore, based on the aforementioned issues, the research team led by Lei Wang from Westlake University designed an N-heterocycle-based deep eutectic solvent scheme by combining the characteristics of hydrogen bond acceptors (such as pyrazole) and hydrogen bond donors (such as lactic acid, formic acid, and acetic acid). After screening various extraction conditions, this method achieved one-step complete depolymerization of coexisting C-lignin and G/S-type lignin in the seed shells of Euphorbiaceae. The results showed that not only was C-lignin extracted with high yield and high purity, but it also produced a single product stream of propyl catechol after Pd/C catalytic conversion. This study aims to utilize N-heterocycle-based deep eutectic solvents for the selective depolymerization of coexisting C-lignin and G/S-type lignin in the seed shells of Euphorbiaceae, especially for the efficient, pure, and green preparation of C-lignin, providing a viable solvent strategy for converting the seed shells of Euphorbiaceae (such as Chinese tallow tree, castor, Java creeper, wax gourd, and tung oil tree) from biodiesel waste into high-value-added products.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track