Researchers achieve green synthesis of polyamide 12 using biomass sugars

Artificially synthesized polyamides, as an important class of industrial materials, are widely used in industries such as automobile manufacturing, oil pipelines, electronics, sports equipment, and medical devices, with a global market size exceeding 100 billion RMB. As the world's largest consumer market for polyamide materials, China has an annual demand of several million tons. However, the core chemical monomers for synthesizing polyamide 12 have long been monopolized by a few companies, posing significant supply risks to businesses. In addition, the synthesis of polyamide 12 relies on petroleum extraction, and the production process is highly polluting to the environment. Therefore, developing more green and sustainable technologies for the synthesis of polyamide 12 is particularly necessary.

Recently, the Howard H. Chou group from the Synthetic Biochemistry Research Center of the Institute of Synthetic Biology at the Shenzhen Institutes of Advanced Technology, Chinese Academy of Sciences, published an important research result titled "Biosynthesis of 12-aminododecanoic acid from biomass sugars" in the journal Metabolic Engineering.

The biosynthesis of 12-aminododecanoic acid (ADDA), a chemical monomer for polyamide 12, faces two major technical bottlenecks: first, the intermediate dodecanoic acid (DDA) is toxic to chassis cells; second, the accumulation of the peroxidation byproduct dodecanedioic acid (DDDA) reduces yield and increases production costs. Based on synthetic biology principles, this study elucidated the mechanisms behind these two technical bottlenecks and developed high-yield strains. This research not only deepened the understanding of the biosynthetic mechanisms of DDA, ADDA, and DDDA but also provided new insights into the green production of various polyamides.

Current research on the biosynthesis of ADDA mainly uses plant oils as raw materials, which face challenges such as high raw material prices, resource competition with food production, and associated greenhouse gas emissions and biodiversity destruction. Additionally, the biosynthesis of ADDA accumulates large amounts of DDDA, and its synthesis mechanism remains unclear (Schrewe et al., 2013; Ladkau et al., 2016; Ahsan et al., 2018). Although previous studies have achieved the synthesis of 471.5 mg/L of ADDA using glucose, the cytotoxicity of DDA still limits the improvement of yield and productivity (Ge et al., 2025).

Although the biosynthesis of ADDA provides a new paradigm for the sustainable production of polyamide 12, achieving green synthesis still requires addressing issues such as raw material selection, DDDA accumulation, and DDA cytotoxicity.

Addressing the Cytotoxicity of DDA

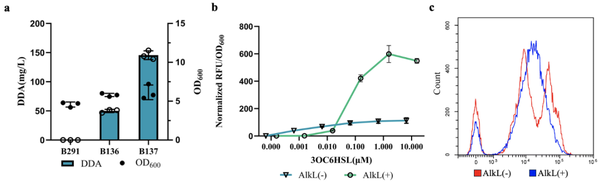

Experiments involving DDA addition and thioesterase (UcfatB) expression indicated that DDA is toxic to growing cells and suggested that excessive UcfatB expression can lead to a state unfavorable for DDA synthesis. The study hypothesized that the use of a quorum sensing expression (QSE) system might help regulate UcfatB expression, thereby promoting DDA synthesis. At low cell densities, the QSE system can maintain UcfatB expression at a low level during the early, more sensitive growth phase, avoiding cytotoxicity while allowing DDA accumulation. As cell density increases, after the sensitive phase, increasing UcfatB expression can maximize DDA production. Compared to constitutive expression systems, the use of the QSE system increased DDA production without inducing cytotoxicity. By combining the alkane transporter (AlkL) with the QSE system, the dynamic performance of the system was further optimized, enhancing expression intensity and uniformity while reducing background expression levels.

Figure 1. Optimizing the QSE system for fine control of DDA synthesis. (a) OD600 and DDA yield with UcfatB expressed by a constitutive promoter or a QSE-based system. (b) Expression strength of the QSE-based system under different inducer concentrations. (c) Flow cytometry analysis of cells expressing mCherry based on the QSE system.

Addressing DDDA Accumulation

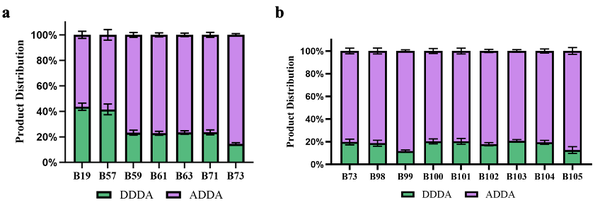

During the conversion of DDA to ADDA, the intermediate 12-oxododecanoic acid may be irreversibly oxidized to DDDA. Previous studies have shown that knocking out enzymes with aldehyde reduction or oxidation activity in E. coli can increase the accumulation of aromatic aldehydes (Kunjapur et al., 2014; Butler et al., 2023). This study successfully reduced DDDA accumulation by knocking out 16 aldehyde dehydrogenases and reductases.

Figure 2. Elucidating the mechanism of DDDA synthesis. (a) Sequential knockout of 7 aldehyde dehydrogenases, and (b) individual knockout of 9 aldehyde oxidases or reductases, and their effects on DDDA accumulation.

Synthesis of ADDA from Glucose and Cellobiose

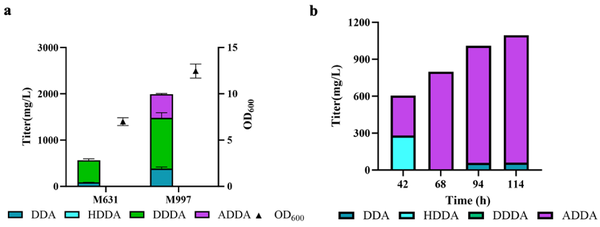

Based on a deeper understanding of DDA cytotoxicity and the mechanism of DDDA synthesis, the researchers engineered E. coli to convert glucose and cellobiose into ADDA, while reducing DDDA accumulation and the negative impact of DDA on cell growth. Under conditions where cellobiose was the primary carbon source, strain M997 achieved an ADDA yield of 509 mg/L. Strain M1001 reached 1035 mg/L in a 15-liter fermenter, with a sugar-to-ADDA conversion rate of 5%, and no detectable DDDA accumulation.

Figure 3. High-efficiency strains for ADDA synthesis from sugars. (a) M631 expressing β-glucosidase fused with OsmY (M997) with cellobiose as the primary carbon source. (b) Fermentation results of M1001.

To achieve a one-step fermentation process for the synthesis of ADDA from glucose and cellobiose, this study elucidated the bottleneck mechanisms in the biosynthesis of ADDA, finding that growing cells are more sensitive to the rate of DDA accumulation than the final DDA concentration. It also identified key genes responsible for DDDA accumulation. By improving the performance of the QSE system and more strictly regulating enzyme transcription, the study significantly enhanced the efficiency of DDA and ADDA synthesis. Finally, the developed one-step process for ADDA production achieved the highest yield and productivity to date from sugar, providing new ideas for more sustainable production of ADDA, polyamide 12, and other polyamide products in the future.

Gao Haixin, a master's graduate, and Fang Qiang, a research assistant, both from the Shenzhen Institutes of Advanced Technology, Chinese Academy of Sciences, are the co-first authors of the paper. Senior Engineer Howard H. Chou is the corresponding author. This research was supported by the National Key R&D Program, the National Natural Science Foundation of China, the Shenzhen Institute of Synthetic Biology Innovation, and the Shenzhen Major Scientific and Technological Infrastructure for Synthetic Biology Research.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track