Over 40% Penetration Rate by 2025! Why Has Yonghua's YU Series Injection Molding Machine Become the Top Choice for New Energy Vehicle Manufacturers?

According to the CPCA data, the cumulative retail sales of new energy vehicles from January to February 2025 were 1.835 million units, a year-on-year increase of 52%, with the penetration rate soaring to 40.3%. This trend not only marks the gradual mainstreaming of new energy vehicles in the market but also brings huge development opportunities to the related industrial chain.

According to the "Technology Roadmap for Energy-saving and New Energy Vehicles," by 2030, the vehicle weight reduction rate in our country will reach 35%. Due to its low density and high strength characteristics, plastic material has become a key material for achieving vehicle lightweighting. As the core equipment for the production of plastic components, the demand for injection molding machines continues to grow.

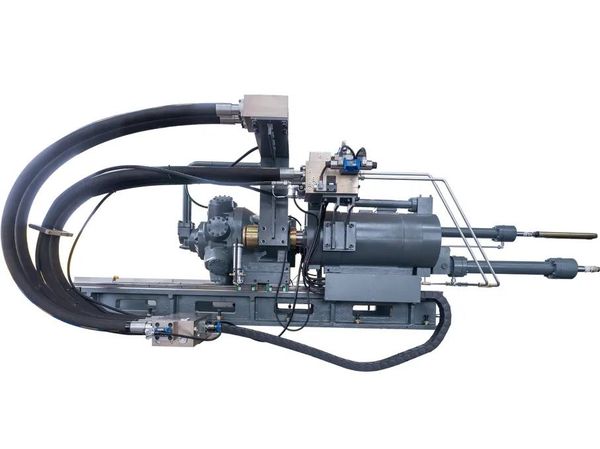

The rapid development of new energy vehicles has placed higher demands on the precision, stability, and overall weight of components. Yonghua Plastic Machinery, targeting the key factor of vehicle weight that restricts the development of new energy vehicles, has launched the YU series of injection molding machines. This series of models, through their excellent injection molding capabilities, empower product lightweighting, creating plastic products that are both lightweight, smooth and flat, complex in shape, strong in impact resistance, and precise in size, reducing component weight in multiple aspects.

At the same time, the YU series of injection molding machines, with features such as small footprint, large mold capacity, fast production cycle, and excellent molding effects, provide lightweight solutions for vehicle and component manufacturers through superior product performance, helping to reduce burden and increase speed in productivity, fully meeting the high-efficiency production demands of the new energy vehicle industry.

YU series

1

high-precision closed-loop control

Adopting high-response ratio directional valves and high-precision electronic rulers, full closed-loop control on the mold closing side is achieved, ensuring fast response, stable operation, and high precision, meeting the stringent requirements of automotive parts for accurate dimensions and stable weight.

2

twin-cylinder parallel injection + linear guide rail

The injection side adopts a dual-cylinder parallel structure and linear guide rail design, making operation more stable, with a comprehensive improvement in injection accuracy and response speed, easily meeting the production requirements for complex shapes and impact-resistant plastic products.

3

rapid mold change + synchronous braking

Diagonal balanced force distribution of the rapid moving mold cylinder significantly shortens the mold opening and closing cycle; the synchronous braking mechanism, in conjunction with the short-stroke high-pressure cylinder, rapidly establishes clamping force, greatly improving production efficiency.

4

high-performance KEBA computer

Equipped with intelligent KEBA computer, flexibly adjust production parameters, helping manufacturers achieve maximum productivity.

5

high rigidity box-type template design

The structure is simple and compact, saving about 20% of space, with a more worry-free operation process, more convenient maintenance, lower energy consumption, and overall cost savings for customers.

As the new energy vehicle market continues to grow, Yonghua Plastics Machinery will continue to focus on technological innovation, promoting the digitalization and intelligent upgrade of the YU series injection molding machines.

In the future, Yonghua Plastics Machinery will be dedicated to providing more competitive solutions for global new energy automotive industry customers, contributing to the sustainable development of the industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track