Nike technology innovation and material application

Nike was founded in 1964, initially called Blue Ribbon Sports, by Bill Bowerman and Phil Knight. In 1971, it was officially renamed Nike. The brand's core values are innovation, speed, and the sport spirit, aiming to enhance athletes' performance through high-performance products, and then expanding into fashion and lifestyle.

Representative Innovation and Material Application

Air technology (Nike Air)

The Nike Air cushioning system was invented by aerospace engineer Frank Rudy in the 1970s and first applied to the Nike Tailwind running shoe in 1978. It provides a lightweight and cushioned effect by embedding Air Sole units filled with compressed gas in the sole, enhancing comfort and rebound during running and athletic activities. TPU is the primary material for Nike Air cushions, characterized by high elasticity, wear resistance, and durability.

Key Development Stage: 1. **Prototyping**:在产品的概念和设计上进行实用性测试和验证。 2. **Testing**:通过各种测试来确保产品的性能、安全性和可靠性。 3. **Production**:生产和交付产品。 4. **Launch**:在市场上推出产品。 5. **Maintenance**:根据市场反应进行产品的改进和维护。 6. **End-of-Life**:在产品的使用期末交付和处理。

1987: Introduced Visible Air, first used in the Air Max 1, allowing consumers to directly see the air cushioning structure.

1990s: Nike continuously improved the air cushion structure, introducing full-length air cushions (such as Air Max 97) and Tuned Air (such as Air Max Plus), further optimizing cushioning and support performance.

2006: Introduced Air Zoom technology, providing a thinner and closer-to-the-ground cushioning experience compared to traditional Nike Air.

Since 2008: Nike Air cushioning has used at least 25% recycled manufacturing waste, and all Nike Air manufacturing facilities have used 100% renewable wind energy.

In 2024, the Air Max 1000 will be launched, featuring a 3D-printed Air Sole unit that further reduces material waste and enhances sustainability.

Air Max 1000, a completely new 3D printed shoe model developed in collaboration with Zellerfeld, reimagines the iconic Air Max 1 and marks a new expression of Nike's signature Air technology. Source: about.nike

FLYKNIT

Flyknit technology is an innovative upper manufacturing process, first introduced in 2012, designed to provide a lighter, more breathable, and environmentally friendly solution for athletic footwear. Flyknit is approximately 19% lighter than traditional upper materials, enhancing athletic performance. Compared to traditional upper manufacturing, the Flyknit production process reduces material waste by approximately 60%. It reduces stitching and seams, improving durability and comfort.

Development History:

2012: Flyknit first applied to the Flyknit Racer, setting a new standard for woven shoe upper technology.

2014: Launched Flyknit Lunar, combining lightweight foam for enhanced cushioning.

In 2016, Flyknit entered the professional sports shoe market, such as in football shoes and basketball shoes, like the Mercurial Superfly and Kobe 11.

2020: Introduced the Space Hippie line, with Flyknit using a higher percentage of recycled materials, further reducing the carbon footprint. Currently, approximately 50%-100% of Flyknit material comes from recycled plastic bottles, with each pair of shoes using an average of 6-7 recycled plastic bottles.

2023 Nike Air VaporMax Flyknit 3D combines full-length foam cushioning and Flyknit, enhancing comfort and sustainability.

NikeSkin

NikeSkin is a high-performance upper material technology developed by Nike, first applied in the 2013 Hypervenom soccer shoes. This technology aims to provide better fit, flexibility, and durability while enhancing the touch performance of the footwear. NikeSkin combines a super-thin polyurethane (PU) film with highly elastic mesh, allowing the upper to snugly conform to the foot while offering strong protection and durability. NikeSkin uppers are lighter and thinner than traditional synthetic materials, and they are more abrasion-resistant compared to conventional mesh materials, making them suitable for high-intensity sports. Some versions feature an ACC (All Conditions Control) coating, which maintains stable touch and ball control performance in wet conditions.

Development History:

2013: First application on Hypervenom Phantom football boots, offering superior feel and flexibility.

2014: Nike Skins were updated in the Magista and Mercurial series to improve breathability and ball control.

2016: Combined with Flyknit, applied to Hypervenom Phantom 3, enhancing fit and comfort.

2020: Developed a thinner and lighter NikeSkin for the Mercurial Vapor 14, enhancing the performance of speed-oriented players.

In 2023, NikeSkin is widely used in the Tiempo Legend 9, Phantom GX football boots, enhancing ball control accuracy, and further optimizing durability and waterproof capabilities.

Foaming and shock-absorbing materials

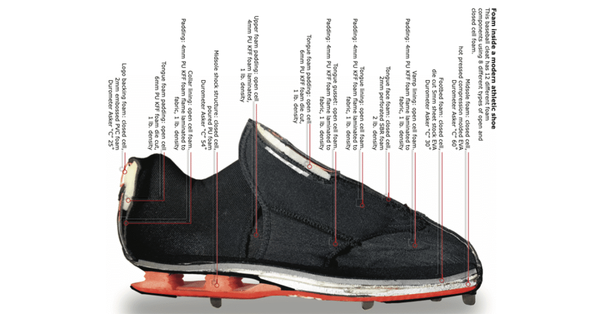

In sneakers, there are usually Several types of foam insoles, including the pores of open-cell foam and closed-cell foam.

Nike's foam materials have evolved from EVA to Phylon to Cushlon to Lunarlon to React to ZoomX, with each generation of foam improving in weight, durability, energy return, and environmental friendliness. Additionally, Nike is also actively exploring eco-friendly foams, such as Crater Foam and LanzaTech carbon-captured EVA.

This Nike shoe features six different types of foam inside. Source: shoemakersacademy

Representative Foaming Technology and Materials

Phylon

EVA, after being heated and compressed into shape, has a low cost and provides basic cushioning.

Nike's former patent technology, Phylon, involves twice heating and foaming plastic particles, which are then injected into a mold under pressure and cooled. During the foaming process, the material's density can be controlled by adjusting the temperature.

Cushlon

Rubber EVA is softer than cotton canvas, has better shock absorption.

Lunarlite

Lunarlite is a lightweight foam cushioning material that is compared to EVA, which is 30% lighter than traditional EVA.

Lunarlite was first applied to Hyperdunk 2008, a basketball shoe that broke performance boundaries not only on the field but also due to its historical significance and technological value. Hyperdunk 2008 was designed by Nike's renowned designer Eric Avar. The shoe was paired with Zoom Air and Flywire technology.

Nike and Kobe Bryant launched the Nike Hyperdunk, Source: dexigner

Unarlite is the predecessor of Lunarlon foam, and they share certain similarities in structure and performance. However, Unarlite offers higher energy return and lighter weight. Unarlite is often combined with Phylon or other firmer foams to create a dual-density cushioning system, providing better stability. Compared to the later React and ZoomX, Unarlite tends to lose its elasticity more easily when compressed and has relatively lower durability, which is why it was gradually replaced by Lunarlon.

Lunarlon

Lightweight ethylene-vinyl acetate (EVA) and elastic nitrile rubber (NBR) are combined to create a material with elasticity similar to that of a bouncy ball. In 2005, the Nike team used the Lunarlon cushioning prototype for the soles of their running shoes. The soft yet stable Lunarlon was injected into a firmer, more supportive Phylon foam outer shell.

Nike Lunar Cross features the all-new full-palm Lunarlon cushioning system. Source: Nike Inc.

React (用于日常训练、跑鞋)

High durability, good cushioning and energy return, lighter than traditional foams with more持久性和更好的回弹。较传统泡棉更轻、弹性更持久。 请允许我重新翻译这段内容以确保其准确性和通顺: High durability, excellent cushioning and energy return, lighter than traditional foams with more durable elasticity.

Compared to Cushion foam, React is 11% lighter and provides 13% more energy return.

Nike React technology was first applied to basketball products in June 2017. The surface features a complex texture with varying depths; the deeper areas provide greater cushioning, while the shallower areas offer more support. Source: nikeinc

ZoomX

The lightest and most energy-returning foam to date. Based on Pebax® material (polyether block amide), it features extremely high energy return and lightweight characteristics.

This foam was first introduced in the Nike Zoom VaporFly 4%, which was worn by 2016 Olympic gold medalist Eliud Kipchoge when he won the Breaking2 marathon with a record time of 2 hours and 25 seconds.

Crater (Eco Foam)

Made from Nike Grind recycled materials (production waste), reducing carbon emissions, with a texture similar to React but slightly firmer.

Crater Impact is created based on Nike's regeneration concept.

LanzaTech is an American company that specializes in the production and recycling of polyethylene terephthalate (PET) and other carbon products.

Convert CO2 extracted from industrial waste gas into EVA foam, reducing carbon footprint, used in Nike Air Zoom Alphafly NEXT% 2 (some versions)

Nike Grind

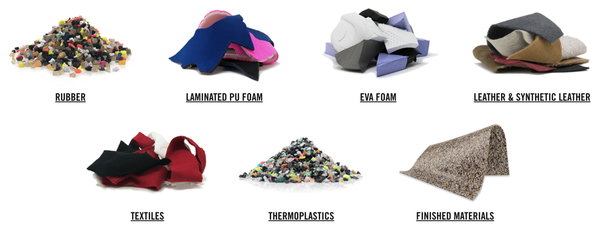

Nike's recycled materials collection is made up of pre-consumer manufacturing waste, post-consumer shoes from the Reuse-A-Shoe program, and unsold shoes. The purpose of Nike Grind is to eliminate waste according to the principles of sustainable fashion practices and to complete the closed loop of Nike's product lifecycle. The recycled materials include rubber, foam, fibers, leather, and textile blends, which are separated and ground into particles.

Nike Grind materials are used in a range of Nike products, including footwear, apparel, and the yarns that make them. These materials are also used in running tracks, turf fields, sports court surfaces, courts, weight room floors, and carpet padding.

Fitness equipment

Sound absorbing materials

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track