Medical material polylactic acid (PLA) has been updated to the third generation!

First, let's directly present the first conclusion, which is different from what everyone imagines. Also due to the naming rules, polymer materials can have countless possible structures because of their molecular design. Different structures exhibit different material properties; from a physical perspective, there is a vast research space for their crystal hardness, viscoelasticity, and other physical properties; from a biological perspective, it is also necessary to study the antimicrobial properties of polymer materials and their compatibility with organisms. Therefore, although they may share the same polymer name, materials under the same name can have vastly different clinical performances or safety levels; this mainly concerns the scientific research and technological levels in two aspects: raw materials and end products; that is, both in terms of raw material quality control (polymer chemistry) and preparation technology (polymer physics), one must achieve a leading position, and this is not easy!

Polylactic acid, as a representative of polymer materials, is relatively common in our daily lives. It includes, for example, commonly used environmentally friendly and biodegradable straws, cups, etc., which use civilian-grade raw materials; it also includes high-strength biodegradable human implant materials such as bone nails and bone plates, which use medical-grade raw materials, while injectable PLA requires medical-grade raw materials.

Polylactic acid PLA, as a facial filler in the medical aesthetics industry, has undergone about 20 years of development through three eras, which can generally be divided into 1.0, 2.0, and 3.0; that is, 1.0 crystalline flake; 2.0 generally rough-surfaced porous microspheres or solid microspheres; 3.0 uniform particle size, smooth-surfaced solid microspheres.

The representative work of the 1.0 era, of course, is the well-known DermaVeil (not launched in the Chinese market) and another imported youth needle S under the G brand that has just been approved in mainland China, which always cannot avoid two issues:

1. Unable to completely escape the dilemma of being difficult to dissolve, it is easy to produce nodules;

2. Baby-face injections S, including the entire regenerative category, have never occupied a large share in the overseas medical aesthetics market.

2.0 Era Masterpiece - Microspherical PLA

The times are progressing, and people have found that the form of materials determines their clinical performance. The crystalline sheet PLA in the European and American markets has been criticized for various reasons, so in the Asia-Pacific region, some upstream material suppliers have made improvements based on 1.0, thereby evolving PLA from a crystalline sheet to a spherical form. The representative work of the 2.0 era is PDLLA microspheres (which also include some PLLA microsphere products where raw material quality control and preparation processes have not yet been fully refined). Under a microscope, the 2.0 era PDLLA microspheres appear as rough-surfaced porous microspheres.

What's good about the 2.0 era?

First, relevant literature shows: the 2.0 era spheres indeed made the resuspension by doctors more convenient, also meaning that the probability of nodule formation is lower compared to 1.0 era products represented by S.

material composition

Why not directly make a PLA poly-L-lactic acid microsphere, but instead introduce the less desirable substance PDLA poly-D-lactic acid, evolving into PDLLA poly-DL-lactic acid microspheres? It is well known that there are no enzymes in the human body to metabolize poly-D-lactic acid. The D-lactic acid produced by the degradation of poly-D-lactic acid (PDLA) can accumulate and lead to acidosis, causing neurotoxic effects. Therefore, D-lactic acid is prohibited in infant and young child food, and the daily intake of D-lactic acid for adults is limited to below 100mg/kg body weight.

And for the medical aesthetics industry, since the customer base is inherently healthy, upstream material suppliers should adhere to the "non-rescue principle" in developing products that are extremely safe, do not compromise the health of the beauty seekers under the premise of doctors' standardized operations.

Not making pure PLLA microspheres, there is a possibility that the optical purity in the production process cannot be controlled, meaning that due to production process limitations, it was not possible to make purely left-handed lactic acid microspheres in the 2.0 era. Another possibility is that the hardness of the PDLLA porous spheres themselves is problematic, and to address the fragility of the spherical structure, it was necessary to add PDLA to the PLLA to enhance its hardness.

material form

Secondly, due to its structural form being rough-surfaced porous microspheres, this leads to a potentially uncontrollable degradation process, which can result in two undesirable situations:

1- During the degradation process, the sphere is impacted by external forces and suddenly collapses. After collapsing, it may form flake-like crystals similar to those of the 1.0 era again, leading to adverse reactions such as nodules.

2-Due to being "rough-surfaced" porous microspheres, they generate static electricity after friction, making them extremely prone to aggregation. After aggregation, they can still be further enveloped by macrophages, forming inflammatory tissues or causing nodules.

The above is just an inference made based on the form of the material.

Professionals indicate that the preparation and mass production of medical-grade polylactic acid raw materials have very high process barriers. Taking the preparation of poly-L-lactic acid as an example, this material is highly sensitive to moisture, has unstable properties, and is prone to decomposition, making it difficult to produce at high purity and high yield. Therefore, in the selection of medical-grade polylactic acid raw materials, key parameters such as purity, monomer (lactic acid) residue, and solvent residue need to be closely monitored, and meeting these standards at a high level is not easy. Thus, obtaining a relatively perfect PLA product is no simple task.

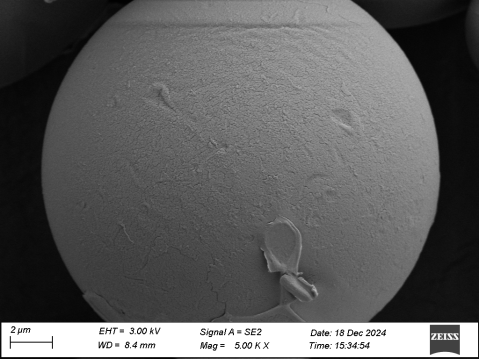

So, what does the pure PLLA microsphere of the 3.0 era look like?

In terms of morphology, they are smooth-surfaced solid microspheres. Not only do they not require a long re-dissolution time like traditional PLLA from the 1.0 and 2.0 eras, which can increase the risk of infection (a long re-dissolution time also means poor solubility, making it more likely to form nodules after injection), but they can also avoid the formation of "annoying bubbles." These "annoying bubbles" may contain aggregates of particles, which not only could clog the needle but also increase the risk of nodule formation.

In the 3.0 era, a very important part of the process is controlling the degradation rate of microspheres. The microsphere preparation process in the 3.0 era controls the microspheres to degrade uniformly over 2 years (106 weeks). This means that within these 2 years, the degradation rate of the microspheres remains constant and uniform, which implies stable clinical effects: it will not happen that some people have particularly long-lasting effects while others have particularly short ones. This is somewhat similar to a "sustained-release" effect, continuously releasing lactic acid, exerting a stable regenerative function, achieving self-stable collagen growth and lower inflammatory reactions, reaching a gradual, natural outcome.

PLA, as a currently popular medical material, has seen advancements in material and improvements in safety from version 1.0 to 2.0 to 3.0 due to the refinement of preparation techniques. We have also found that only by iterating the process at both the raw material and end product stages can we promote the improvement of products. From raw materials to final products, coordinating quality control from the source is the way to produce high-quality products from the "root."

With the development of science and technology, the advancement of marketization and informatization in China, and the significant improvement in consumer awareness, as an upstream manufacturer, it is necessary to continuously focus on product strength, be guided by consumer interests and demands, and persistently strive for excellence in research and development as well as in product upgrades and iterations.

A decade ago, the era of entering the Chinese market with just a marketing gimmick or with products that were difficult to sustain overseas to make high profits is long gone.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track