Lianhong Xinke: PLA has produced qualified products, and the 50,000-ton PPC project will be put into production in 2025.

On March 28, Lianhong Xinke (003022) disclosed its 2024 annual report. In 2024, the company achieved a total operating revenue of 6.268 billion yuan, a year-on-year decrease of 7.52%; the net profit attributable to shareholders was 234 million yuan, a year-on-year decrease of 47.45%; the net profit excluding non-recurring gains and losses was 185 million yuan, a year-on-year increase of 2.00%; the net cash flow generated from operating activities was 594 million yuan, a year-on-year decrease of 32.18%; during the reporting period, Lianhong Xinke's basic earnings per share were 0.18 yuan, and the weighted average return on net assets was 3.27%. The company's distribution plan for 2024 is to propose a cash dividend of 0.6 yuan (including tax) for every 10 shares held by all shareholders.

Lianhong Xinke is a supplier of new material products and solutions, mainly engaged in the research, development, production, and sales of advanced polymer materials and specialty fine materials. Its business segments include new energy materials, biodegradable and bio-based materials, electronic materials, and other specialty materials.

The biodegradable materials that Lianhong Xinke has invested in include PLA and PPC, which are produced by its subsidiaries Jiangxi Institute of Biological New Materials Co., Ltd. and Lianhong Gerun (Shandong) New Materials Co., Ltd.

The PLA project adopts an independently developed "starch - high-purity lactic acid - high-purity polylactic acid - polylactic acid" complete industry chain technology. The 100,000 tons/year lactic acid facility and 40,000 tons/year PLA facility have been completed and put into operation in 2024, producing qualified PLA, which has begun to be marketed and is developing new application scenarios such as 3D printing.

The 50,000 tons/year PPC project under construction is planned to be completed and put into production in 2025. The main raw materials, PO and carbon dioxide, are all produced in-house, which not only shows a significant advantage in the industrial chain but also helps reduce carbon dioxide emissions. The project employs the latest generation of catalyst technology developed in collaboration with relevant institutes of the Chinese Academy of Sciences, which can be completely degraded under natural conditions and possesses advantages such as good toughness and rigidity balance, excellent barrier properties, and high transparency.

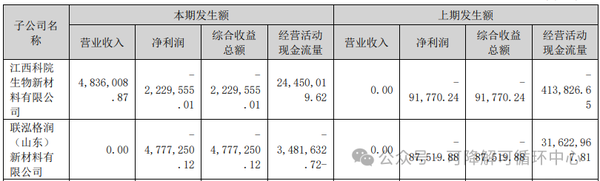

Financial information of subsidiaries related to biodegradable materials

Lianhong Xinke stated that in the future, it will continue to increase its business layout in the field of biomaterials, intensify investment in biodegradable and bio-based materials, and actively promote the development and industrialization of new bio-based sweeteners and other new biomaterial technologies.

About PLA

PLA is a type of artificially synthesized polymer material and is one of the important biodegradable materials, characterized by its bio-based and degradable properties. PLA has high heat resistance and mechanical strength, and it can be compatible with traditional plastic processing techniques. It can be processed through methods such as extrusion, injection molding, blow molding, spinning, and foaming. Its applications are increasingly widespread in 3D printing, food and pharmaceutical packaging, and fiber textiles. According to statistics, the domestic demand for PLA is expected to reach approximately 120,000 tons in 2024, with a year-on-year growth of 48.1%. Among these, 3D printing is currently the largest application field for PLA, accounting for about 35% in 2024. 3D printing materials based on PLA are widely used in fields such as cultural and creative products, complex structural components required by smart devices, and lightweight components due to their environmental friendliness, ease of use, good mechanical properties, safety, and cost advantages. In the future, with the rapid development of downstream industries and the promotion of national carbon neutrality policies, PLA, as a high-performance material, aligns with the concepts of green manufacturing and sustainable development. It is expected to achieve rapid growth in high-end manufacturing, intelligent equipment, toys, education, healthcare, green packaging, and eco-friendly clothing sectors.

PLA Material Application Scenarios

About PPC

PPC is a new generation of high-performance "environmentally friendly" biodegradable materials, made from carbon dioxide and PO, which can effectively utilize carbon dioxide, help address "white pollution," and reduce carbon emissions. Compared to other biodegradable materials, PPC has excellent toughness and rigidity balance, good barrier properties, high transparency, outstanding water retention and moisture preservation, and is biodegradable. It is an ideal disposable film material that can replace traditional non-biodegradable materials, especially showing great market development potential in replacing traditional film materials.

PPC material application scenarios

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track