In the second quarter, concentrated maintenance of polypropylene facilities alleviates supply-side pressure.

lead-inShort-term supply-side reduction trend, mainly due to the concentrated maintenance of units such as Jinneng Chemical's second line and Maoming Petrochemical's second line, leading to a future supply-side reduction situation. In the second quarter, with the concentrated maintenance of units, the supply-side pressure may ease.

I. Polypropylene loss data trend stability analysis

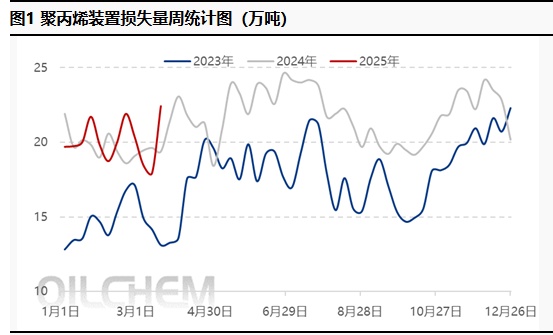

3.1 Conventional Data Analysis of Polypropylene Loss Quantity

As of March 20, 2025, the loss of polypropylene (PP) plant capacity in China was 224,270 tons, an increase of 25.10% from the previous week; among which, the loss due to maintenance was 159,840 tons, an increase of 60.43% from the previous week; the loss due to reduced load was 64,430 tons, a decrease of 19.24% from the previous week. Due to unexpected shutdowns of some large plants such as Zhongjing Petrochemical, and planned maintenance of plants like Pucheng Clean Energy, the domestic maintenance loss exceeded expectations. Affected by the widespread shutdowns, some plants with low operating loads have transitioned to a shutdown state, resulting in a slight increase in the loss due to reduced load for domestic polypropylene plants.

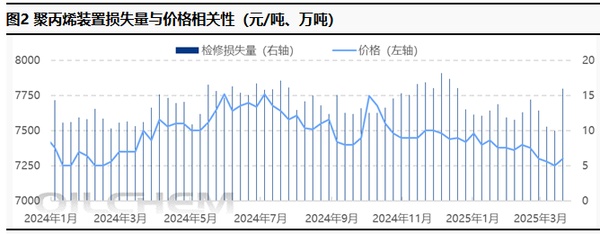

3.2 Loss Quantity Data Price Correlation Analysis

The weekly maintenance loss of polypropylene facilities in China increased by 60.43% week-over-week and 42.35% year-over-year. The maintenance volume of polypropylene facilities in China has hit a new high for the year, 60.43% higher than the lowest point of the year. The surge in maintenance losses of domestic polypropylene facilities has strengthened market support, leading to a significant rebound in market prices.

II. Seasonal Variation Analysis of Domestic Plant Losses

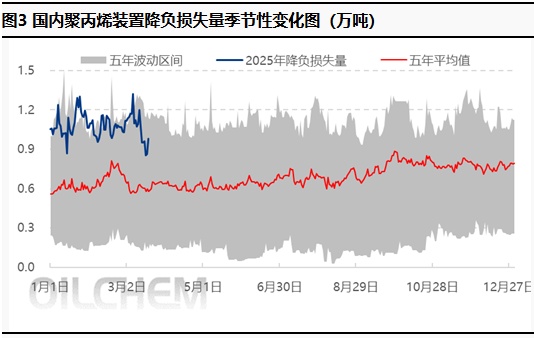

2.1 Seasonal Changes in Load Reduction Vectors

From the perspective of load reduction loss, as more polypropylene units are shut down and some units with low load enter a shutdown state, the load reduction loss of domestic production enterprises has rapidly declined and then experienced a slight rebound. In the future, as maintenance plans for the units gradually increase, the weekly load reduction loss may still have the possibility of fluctuating and declining.

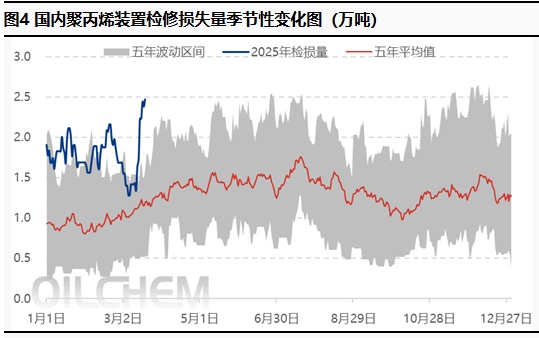

2.2 Seasonal Changes in Maintenance Loss Quantity

In late March, the peak consumption did not unfold as expected, and some production enterprises faced significant inventory pressure, leading to an increased willingness for maintenance. Additionally, unexpected shutdowns of some large facilities resulted in a greater-than-expected increase in maintenance losses. By March 20th, domestic maintenance losses had risen significantly, with the maintenance peak season slightly ahead of previous years.

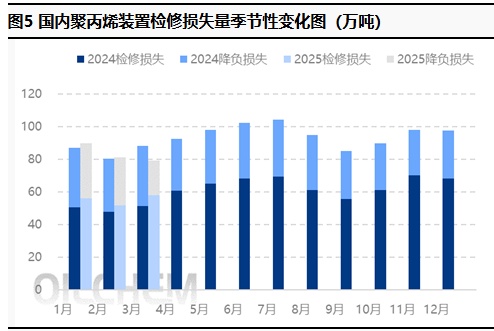

2.3 Seasonal Changes in Monthly Losses of Domestic Polypropylene Plants

As of March 20th, based on the maintenance data currently available, it is estimated that the loss of domestic polypropylene facilities in March will be around 850,000 tons, with maintenance losses at 578,550 tons, an increase of 12.28% month-over-month and a 12.77% increase year-over-year.

III. Details of Domestic Polypropylene Plant Maintenance

3.1 Domestic Polypropylene Maintenance Details for the Month

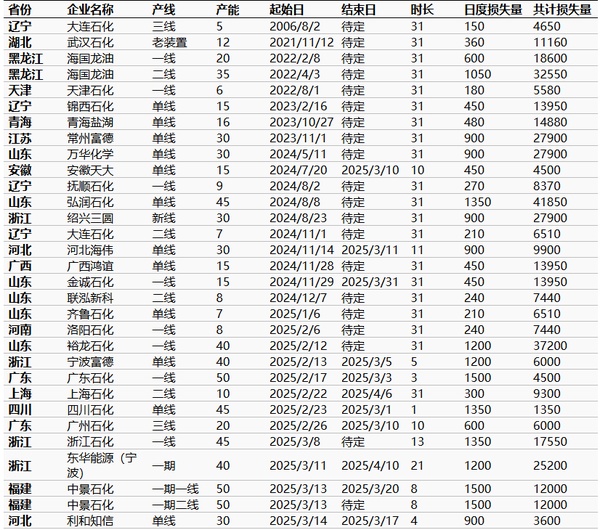

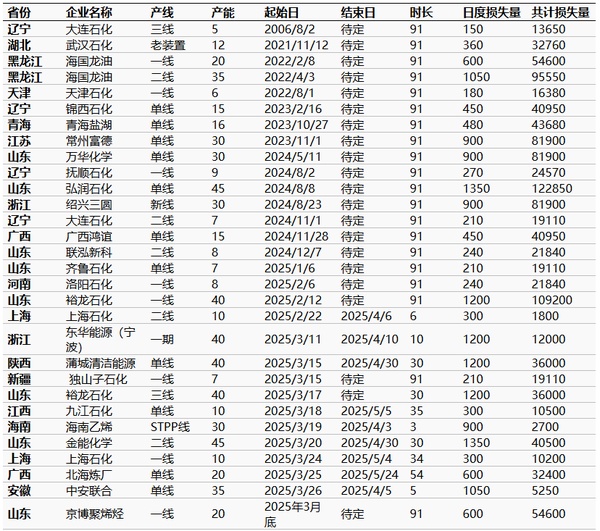

Table 1 March Domestic Polypropylene Plant Maintenance Statistics Table

unit: ten thousand tons/year, day, ton

In March, newly added parking facilities include Zhongjing Petrochemical, Yulong Petrochemical, Jinneng Chemical, and Pucheng Clean Energy. Restarted facilities include Lihe Zhixin, Ningbo福德化工和广州石化三线等。新增检修装置较多,装置检修集中在3月下旬。 翻译如下: In March, newly added parking facilities include Zhongjing Petrochemical, Yulong Petrochemical, Jinneng Chemical, and Pucheng Clean Energy. Restarted facilities include Lihe Zhixin, Ningbo Fude, and Guangzhou Petrochemical Line 3. There were many newly added maintenance facilities, with the maintenance concentrated in late March. 请注意,“宁波富德”在英文中被直接音译为“Ningbo Fude”。如果有官方的英文名称,请替换使用。

3.2 Domestic Polypropylene Maintenance Loss Volume Structure Analysis

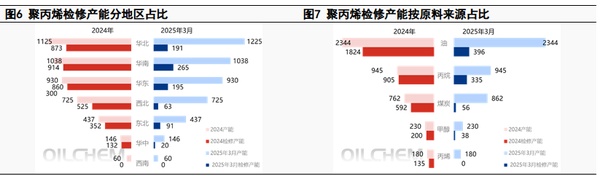

From the 2024 data analysis, the region with the largest maintenance capacity is South China, followed by East China and North China. From the perspective of raw material sources, oil-based, PDH-based polypropylene has a generally higher willingness for maintenance due to cost pressures compared to coal-based polypropylene. In March 2025, South China remains the region with the largest maintenance capacity, followed by North China, mainly because these regions have a larger capacity, and secondly, because the proportion of oil-based/PDH polypropylene in South China/North China is relatively high, leading to a higher preference for shutdown maintenance under the influence of cost pressures.

3.3 Analysis of the Impact of Profit on Polypropylene Plant Maintenance

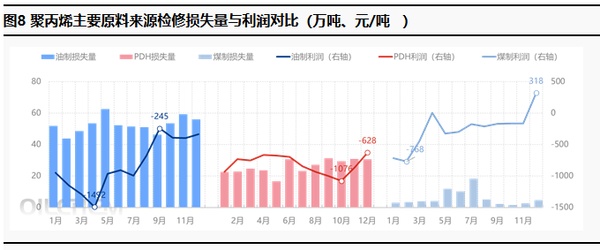

Crude oil, coal, and propane, as the three main raw materials for polypropylene, account for 82% of the total production capacity of polypropylene. Therefore, these three raw materials are used to represent the profit and maintenance loss of polypropylene for analysis.

Affected by geopolitical influences from India, international crude oil prices remain high, leading to a high theoretical cost pressure for oil-based polypropylene facilities, which are on the brink of losses. Due to high freight rates and supply-demand relationships, propane prices have been high for a long time, making the gross profit margin of PDH facilities the lowest among the three types of raw material sources, thus the willingness for facility maintenance remains high. Domestic coal-based polypropylene facilities are mostly built at the mine mouth, with lower coal costs, resulting in less cost pressure and a significant price advantage; therefore, the willingness for maintenance of domestic coal-based polypropylene facilities is low, and the overall renovation rate of the facilities is also low.

IV. Domestic polypropylene is about to enter the peak maintenance season

4.1 Domestic polypropylene future maintenance plan

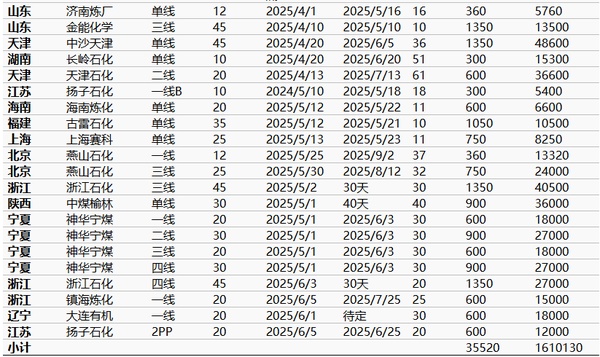

Table 2 Statistics of Domestic Polypropylene Plant Maintenance Plans for the Next Three Months

unit: ten thousand tons/year, day, ton

Regarding the future market, according to statistical data, at the end of March and beginning of April, maintenance plans for domestic polypropylene facilities remain relatively concentrated, with an increase in planned maintenance. It is expected that the overall loss of domestic polypropylene facilities will rise, and the peak maintenance period may occur at the end of May and in June. Pay attention to the impact of new capacity coming online and unexpected shutdowns.

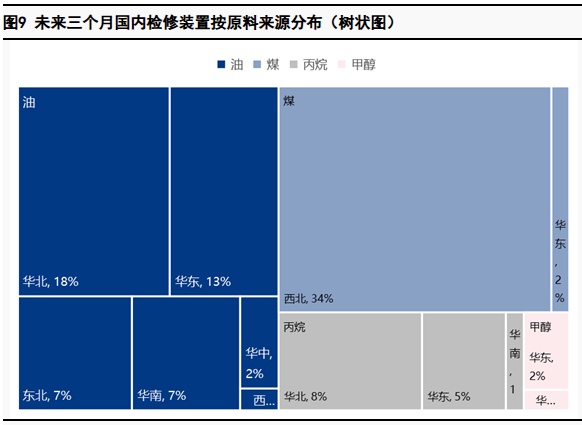

4.2 Future Domestic Polypropylene Maintenance Facility Structure Analysis

From the perspective of future facility maintenance, traditional oil-based polypropylene facilities will still undergo maintenance, and this is true for all major regions, with the highest proportion of oil-based enterprises in North China. For coal-based enterprises, their geographical location is more pronounced, concentrated in the northwest region. There are not many maintenance plans for propane dehydrogenation facilities, which are concentrated in the North China/North China region.

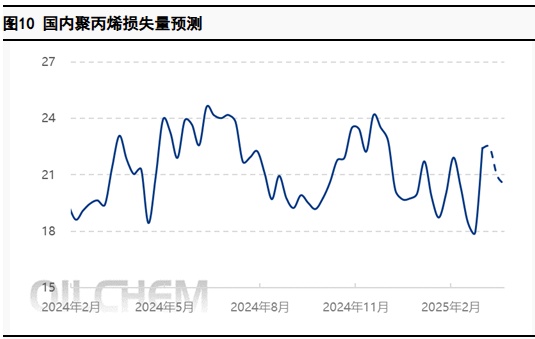

4.3 Maintenance loss prediction and price impact prediction

supply forecast:Expected supply reduction trend, mainly due to the concentrated maintenance of facilities such as Jineng Chemical's second line and Maoming Petrochemical's second line, leading to a future supply reduction situation. Recently, the enterprises under maintenance are concentrated in Pucheng Clean Energy, Anqing Baiju, Zhongjing Petrochemical Phase II Line 1/Line 2, and Yulong Petrochemical.

demand forecastingDownstream rigid demand procurement is the main focus, as the global economic downturn and overseas tariffs have affected some downstream export orders. Under the dual pressure of reduced domestic and international orders, the willingness of downstream raw material procurement to replenish inventory is low. According to plastic weaving data, the raw material inventory days for large enterprises in the plastic weaving sample increased by 2.60% compared to last week; the raw material inventory days for BOPP sample enterprises decreased by 5.39% compared to last week. The raw material inventory days for modified PP increased by 0.79% compared to last week.

cost forecast:Cost support still exists, although there is an expectation of easing in international oil prices, due to recent geopolitical benefits leading to a climb from recent lows in international oil prices; propane follows the trend of international oil prices, with recent downstream market entry supporting prices; propylene has seen limited high-end transmission recently, and is mainly stable in the short term.

In a comprehensive view:The continuous expansion and increase in the supply side contrasts sharply with the weak response from the demand side. The imposition of additional tariffs overseas has curbed downstream export orders, coupled with a slow increase in domestic demand, dragging down the mainstream market transactions. The bottom support for the market lies in the relatively stable cost side and ongoing maintenance benefits, alleviating downward pressure on the market. In the short term, the market will revolve around the confrontation and game between supply and demand and the cost side. It is expected that the market will fluctuate weakly within the range of 7250-7450 yuan/ton in the short term, with close attention to changes in additional tariffs overseas, progress in destocking of social inventory, and the status of demand-side variables. In the medium to long term, prices may see a slight rebound supported by maintenance benefits, fluctuating around 7500 yuan/ton.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track