From Steel to Plastic: Japanese Manufacturers Target Producing Propylene from Steel Byproduct Gas

The project involves the production of propylene using methanol (a byproduct gas from the steel manufacturing process). Hans-Peter Merten/Getty Images

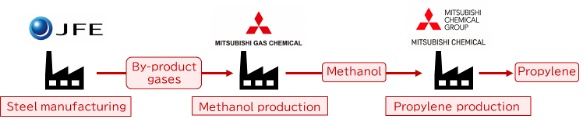

Japanese JFE Steel, Mitsubishi Gas Chemical, and Mitsubishi Chemical recently signed a memorandum of understanding to launch an innovative demonstration project in the Mizushima Industrial Zone of Kurashiki City, Japan, in the fiscal year 2026 (starting from April 2026). The project aims to utilize CO₂-containing byproduct gases generated during the steel manufacturing process to produce methanol, which will further be converted into propylene, the core raw material for polypropylene (PP) plastics, promoting the application of sustainable materials in the automotive, home appliance, and packaging sectors.

2026 Year initiated

The demonstration project is scheduled to commence in fiscal year 2026, starting in April. JFE Steel will supply by-product gases generated during the steel manufacturing process to Mitsubishi Gas Chemical, which will use these gases as raw materials for methanol production in a new demonstration plant to be constructed.

The role of three companies and material flow in a demonstration project. Image provided by Mitsubishi Chemical.

In addition, Mitsubishi Chemical will use methanol to test the compatibility with DTP propylene production technology at its existing pilot facility. The DTP (propylene production leading technology) was jointly developed by Mitsubishi Chemical and JGC Corporation, utilizing highly selective catalysts for low-energy and high-yield propylene production.

CO2Utilize

This demonstration project represents a new initiative within the Mizushima Complex, aimed at fostering collaboration among hard-to-abate industries—those where greenhouse gas (GHG) emissions are difficult to reduce. The project utilizes CO₂ contained in by-product gases from steel manufacturing to produce valuable chemicals, providing a model for the synergistic use of CO₂.

Looking ahead, this initiative aims to develop a conceptual framework for carbon recycling through collaboration between the steel and chemical industries. Compared to traditional fossil resource-based chemical production methods, this approach is expected to reduce greenhouse gas emissions.

The Mizushima Complex, where these three companies operate, is a high-density industrial area with a concentration of various industries. It is a promising region for cross-industry collaboration on CO₂ utilization. Therefore, these three companies will explore broader collaboration opportunities with other businesses within the Mizushima Complex.

Translated by: Lily

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track