E. coli first produces strong and flexible "nylon"

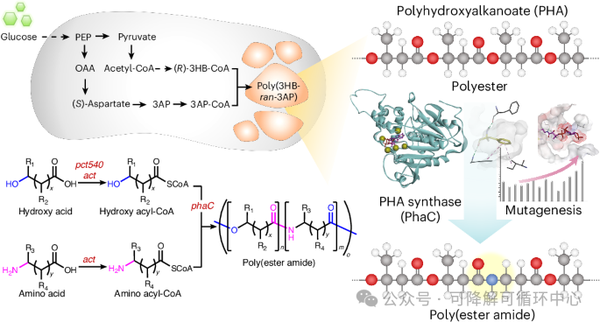

Polyester amide (PEA) is a promising class of polymers containing ester and amide bonds, combining the excellent properties of both polyesters and polyamides: the superior thermal and mechanical properties of polyamides, and the biocompatibility and biodegradability of polyesters. PEA can be used in various industrial applications, such as biodegradable plastics, as well as biomedical applications, including drug delivery systems and tissue engineering. Currently, the synthesis of PEA is limited to chemical methods.

Recently, a team led by Academician Sang Yup Lee from the Korea Advanced Institute of Science and Technology produced a nylon-like tough plastic for the first time through genetic engineering of microorganisms. The related results were published in Nature Chemical Biology on March 17.

Globally, about 400 million tons of non-degradable petroleum-based plastic waste and microplastics are produced annually, threatening the survival of wildlife, as well as human health and the Earth's environment. "This work highlights the role of biology in addressing this crisis," said Colin Scott, the enzyme engineering director at Australia's Uluu company.

The corresponding author of the paper, biomolecular engineer Sang Yup Lee from the Korea Advanced Institute of Science and Technology, said: "Bacteria naturally produce polymers to store nutrients when resources are scarce, but it is challenging to use bacteria to make nylon-like plastics because there are no enzymes in nature that can produce such polymers."

To solve this problem, researchers modified enzyme-encoding genes in a series of bacterial species and inserted them as plasmids (a type of circular DNA) into E. coli, which is commonly used for proof-of-concept work. Then, these genes encoded several new natural enzymes capable of linking molecular chains to produce polymers. The final product is a bioplastic called poly(ester amide) (PEA), which is primarily composed of polyester with a small amount of nylon-like amide bonds.

"Nylon is a 100% polymer containing amide bonds, so there is still a long way to go for bacteria to correctly mimic this plastic," said Li Xiangye.

The tests show that the physical, thermal, and mechanical properties of this PEA are comparable to those of polyethylene, one of the most widely used commercial plastics.

However, Shinichi Taguchi, a bioproduction engineer at Kobe University in Japan, said that due to the low frequency of amino acids binding to polymers, this plastic is unlikely to be as strong as polyethylene. "Adding an amino acid to a polymer typically leads to chain termination, resulting in low molecular weight, underdeveloped polymers."

The research team used large bioreactors to achieve a PEA yield of about 54 grams per liter, indicating that production can be scaled up. However, there are still many obstacles to overcome before this laboratory research can be translated into an industrial process.

Due to their large volume, these PEA aggregates cannot pass through the cell wall, so it is necessary to crush E. coli to release them. In addition, before processing the product into films or particles, a purification process is required.

"Currently, our microbial route is more expensive than oil-based plastics." Li Xiangye said, with further optimization, "it is expected that the production cost will gradually decrease."

Related paper information: https://doi.org/10.1038/s41589-025-01842-2

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track