Shengding High-Tech Materials: TPU Interlayer Deepens Military, Aerospace, and Marine Sectors with Tangible Results

Recently, Shengding New Material Co., Ltd.'s independently developed and produced TPU (Thermoplastic Polyurethane Elastomer) interlayer film products have been successfully applied on a large scale in strategic fields such as high-end military, shipbuilding, and aviation due to their excellent comprehensive performance and stable quality. This breakthrough has ended the long-term technological blockade and market monopoly of foreign companies in this type of high-end material field, providing crucial material support for the independent control of China's high-end equipment manufacturing industry.

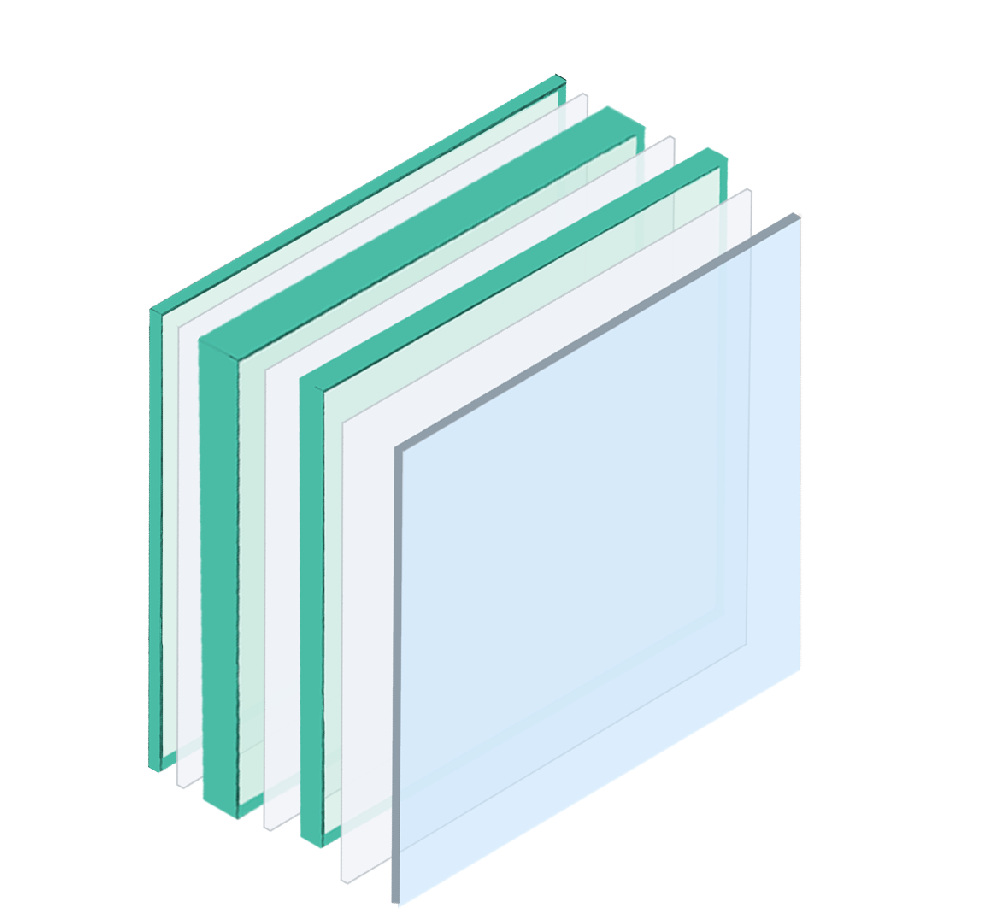

As a high-performance polymer material positioned between rubber and plastic, TPU interlayer combines excellent mechanical strength, low-temperature flexibility, optical transparency, and resistance to extreme environments, making it an indispensable key material in the manufacturing of core components for high-end equipment. For a long time, high-end TPU interlayer technology has been controlled by a few foreign enterprises, leaving China's relevant sectors facing a "bottleneck" dilemma in material supply.

After years of dedicated technical research, Shengding High-Tech Materials Co., Ltd. has assembled a professional R&D team to delve into formula optimization and production process innovation. They have successfully overcome key technical bottlenecks in raw material preparation and precision molding, building a comprehensive TPU interlayer product system covering national standards Class I, II, and III. All performance indicators have reached international advanced levels, with some key parameters exceeding industry standards.

In the high-end military industry, Shen Ding High-Tech Materials Co., Ltd. TPU interlayer films have been widely applied to core components such as armored vehicle bulletproof glass, military explosion-proof vehicle windows, bulletproof masks, and military command post protective glass. The product, with its excellent flexibility maintained even at ultra-low temperatures of -68°C and an impact absorption capability 5 times that of ordinary materials, can effectively disperse bullet impact force and prevent fragment splash, providing comprehensive safety protection for combat personnel. Tested by authoritative institutions, the product's puncture resistance level fully meets military standards, and its adhesion strength far exceeds national standards, with glass + metal peel strength ≥ 50N/cm². It demonstrates exceptional reliability and durability in complex battlefield environments.

In the marine field, facing the special working conditions of high salt spray, strong corrosion, and intense ultraviolet radiation in the marine environment, Shengding High-tech Materials Co., Ltd.'s TPU interlayer film has been successfully applied to key parts such as ship bridge glass, hull protective layers, and life-saving equipment. The product boasts excellent seawater corrosion resistance and anti-UV aging performance, with a transmittance decay of <2% after 3000 hours of UV irradiation and stable performance retention for 50 years, effectively extending the service life of ship equipment and reducing the total life cycle maintenance costs. At the same time, its lightweight characteristics help reduce ship weight and increase efficiency, enhancing navigation performance while aligning with the green ship development trend.

In the aviation sector, Shengding Advanced Materials Co., Ltd.'s national standard Class I TPU interlayer film has passed rigorous airworthiness performance verification and is used in laminated structures of transparent components such as windshields and portholes of domestically produced helicopters, civil airliners, and military transport aircraft. The product strictly adheres to the "General Technical Specification for Thermoplastic Polyurethane Elastomer Interlayer Films for Aerospace" (GB/T43128-2023) standard and has excellent optical performance and extreme environment adaptability. It can maintain stable performance within a wide temperature range of -55℃ to +85℃, resist high vacuum, atomic oxygen, and the erosion of chemical media such as aviation hydraulic oil and de-icing fluid, ensuring clear cockpit visibility and structural safety. Furthermore, in unmanned aerial vehicle fuel storage systems, Shengding Advanced Materials Co., Ltd.'s customized TPU fuel bladder material, with its lightweight and high barrier properties, helps improve aircraft endurance. It has been successfully integrated into a certain type of military reconnaissance UAV, achieving a significant extension of loitering time.

As one of the core enterprises involved in the formulation of national standards for TPU interlayer films, Shengding High-tech Materials Co., Ltd. has consistently driven industrial upgrading through technological innovation. The company has established a comprehensive quality control system encompassing raw material research and development, manufacturing, and testing and acceptance. Shengding can provide customized solutions with thicknesses ranging from 0.38-1.25mm, and adjustable parameters such as light transmittance and viscosity, to meet the diverse needs of different industries. Samples can be provided within 48 hours, offering customers efficient technical support. Currently, the company's products have gained recognition from European defense suppliers and domestic aerospace manufacturing enterprises, and are being supplied in bulk for high-end equipment manufacturing projects.

In the future, Shengding High-New Materials Co., Ltd. will continue to increase R&D investment, focusing on the material needs of strategic fields such as aerospace and high-end military industries. The company will deepen collaborative innovation with research institutions, promote the iterative upgrading of TPU interlayer technology, and expand more high-end application scenarios. By safeguarding the security of national strategic equipment with molecular-level toughness, Shengding will contribute greater strength to the independent and international development of China's high-end materials industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories

-

New 3D Printing Extrusion System Arrives, May Replace Traditional Extruders, Already Producing Car Bumpers

-

Vynova's UK Chlor-Alkali Business Enters Bankruptcy Administration!