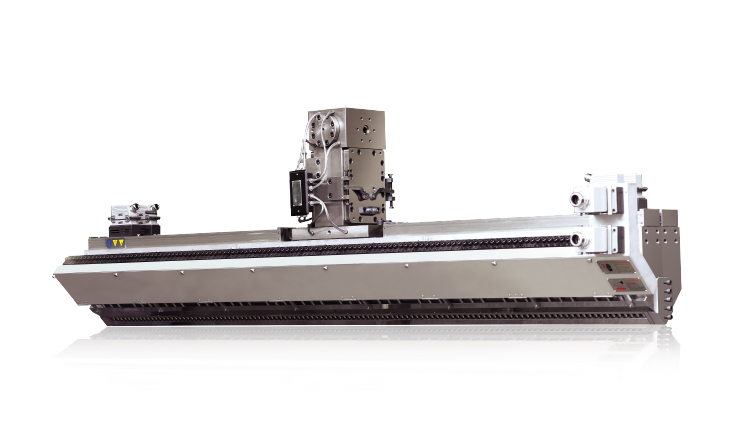

XPE foam material has an independent closed-cell structure, providing excellent thermal insulation and heat retention properties. Additionally, it offers noise reduction and waterproofing features. Its inherent characteristics include heat resistance, aging resistance, chemical resistance, and compliance with international environmental standards. The material is flexible in the form of sheets and can be easily bonded, making cross-linked polyethylene foam sheets widely used in: central air conditioning projects, pipeline engineering, large containers, high-end composite roofing (thermal insulation and soundproofing) systems; luggage lining, anti-static packaging for electronic components such as circuit boards; midsoles for high-end sports shoes; automotive thermal insulation and decorative materials; floating materials for water activities; single or double-coated tape products, etc. Radiation cross-linked foam sheet (IXPE) has a smoother, finer surface with smaller and more uniform cells compared to XPE. It excels in various physical properties and is widely applied in construction, chemical pipelines, thermal engineering, vehicle and ship manufacturing, packaging industry, agriculture, fisheries, sports, and entertainment industries. Currently, this product is still in the growth phase in mainland China, with significant development potential. Jinwei Company's IXPE production line mainly includes three parts: extrusion granulation, extrusion sheet forming, and foaming production.

| Extruder | JWS90 | JWS120 | JWS150 | JWS180 |

|---|---|---|---|---|

| Screw dia.(mm) | 90 | 120 | 150 | 180 |

| L/D Ratio | 25:1 | 25:1 | 25:1 | 25:1 |

| Screw speed R/min | 10~38 | 10~38 | 10~38 | 10~38 |

| Foaming times | 5~35 | 5~35 | 5~35 | 5~35 |

| Cooling method | Water cooling | |||

| Capacity (Max.) Kg/h | 80 | 120 | 180 | 220 |

| Products width(mm) | 1100 | 1100~1300 | 1100~1400 | 1100~1600 |

| Products thickness(mm) | 2.0~6.0 | 2.0~6.0 | 3.0~12.0 | 3.0~12.0 |

| Total power(Kw) | 200 | 315 | 400 | 450 |

| Note: Informations listed above are for reference only, the production line can be designed by customer’s requirements. | ||||

Finished Product Manufacturers

Finished Product Manufacturers

Finished Product Distributors

Finished Product Manufacturers

Finished Product Manufacturers