Upstream And Downstream Inventory Cycle Divergence Again, Polyolefins' Future Is Uncertain

Introduction:

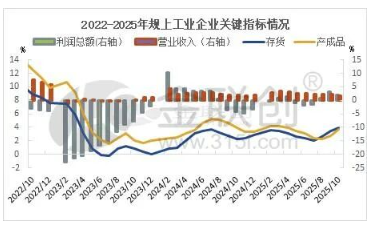

The inventory cycle of upstream and downstream polyolefins has diverged again, with upstream and downstream failing to coordinate efforts. Intermediate industrial products such as rubber and plastic products are actively de-stocking. Upstream polyolefin raw materials are undergoing passive replenishment. This stage is in "stagflation," corresponding to a generally weak fundamental phase, with prices declining.

According to the industrial enterprise profit data released by the National Bureau of Statistics in October, regarding the inventory cycle of industrial enterprises, the inventory fluctuations have led to passive restocking. In specific sub-sectors, there is a divergence in the inventory cycle of the upstream and downstream of polyolefins. Intermediate industrial products, such as rubber and plastic products, remain in an active destocking cycle, while the inventory cycle of raw materials in the chemical raw materials and chemical products manufacturing industry is fluctuating, leading to passive restocking again. The fundamentals of polyolefins remain weak; since 2025, the spot and futures prices of polyolefins have been declining, hitting a new annual low in November. From the perspective of the inventory cycle, the cycle of polyolefin raw materials corresponds to "stagflation," oscillating between "stagflation" and "recession" before falling back to "stagflation" again. Polyolefin prices continued to probe new lows from September to November, and it is expected that in December, they will experience weak fluctuations, with the possibility of further exploring new lows.

Industrial inventory is passive replenishment, and domestic demand remains sluggish.

Data source: National Bureau of Statistics, Jinlianchuang

From January to October 2025, the finished goods inventory of large-scale industrial enterprises nationwide increased by 3.7% year-on-year, with the growth rate improving by 0.9 percentage points compared to the period from January to September; operating revenue grew by 1.8% year-on-year, with the growth rate declining by 0.6 percentage points compared to the previous period, maintaining a continuous shrinking trend since March of this year; total profit increased by 1.9% year-on-year, with the growth rate dropping by 1.3 percentage points compared to January to September. The overall revenue growth of industrial enterprises continues to show a marginal decline, while the improvement in total profit remains unstable. From the perspective of the inventory cycle, there is a repeated interplay between active destocking and passive restocking. Unlike the active destocking before September, the increase in inventory in October can be attributed more to passive restocking driven by insufficient demand, combined with the decline in revenue growth.

In terms of industry categories, out of 40 major industrial sectors, 19 sectors saw year-on-year profit growth, accounting for 47.5% of the sectors. From January to October, the computer, communication and other electronic equipment manufacturing industry increased by 12.8% year-on-year, the textile industry decreased by 6.1%, the electrical machinery and equipment manufacturing industry increased by 7.0% year-on-year, the petroleum and natural gas extraction industry decreased by 12.5%, the automobile manufacturing industry increased by 4.4%, the chemical raw materials and chemical products manufacturing industry decreased by 5.4%, and the rubber and plastic products manufacturing industry decreased by 5.0%.

The upstream and downstream cycles of polyolefins have once again diverged.

Data source: National Bureau of Statistics, JLC Network Technology

From January to October 2025, the total profit of the rubber and plastic products industry fell by 5.0% year-on-year, with the rate of decline expanding by 3.8 percentage points compared to January to September. Operating income increased by 0.7% year-on-year, which is a decrease of 1.5 percentage points compared to January to September. Finished product inventory increased by 3.1% year-on-year, which is 0.1 percentage point lower than January to September; total inventory grew by 1.9% year-on-year, a decrease of 0.5 percentage points compared to January to September. The data indicates an active inventory reduction phase, with market demand continuously contracting, and product prices remaining weak amid a stalemate. Active inventory reduction is being implemented in response to demand contraction, through lowering capacity utilization and reducing production to absorb excess inventory.

Data Source: National Bureau of Statistics, Jin Lian Chuang

From January to October 2025, the total profit of the chemical raw materials and chemical products manufacturing industry decreased by 5.4% year-on-year, with the decline narrowing by 1 percentage point compared to January to September. Operating income grew by 0.2% year-on-year, with the growth rate falling by 0.8 percentage points compared to January to September. Finished product inventory increased by 8.3% year-on-year, with the growth rate rising by 2.2 percentage points compared to January to September. Inventory increased by 3.4% year-on-year, rising by 0.6 percentage points compared to January to September. The industry is currently in a passive restocking phase, primarily driven by insufficient market demand or a decline in industry prosperity, prompting enterprises to passively adjust inventory strategies to address supply-demand imbalances.

The polyolefin market continues to struggle under cyclical influences.

The inventory cycles of upstream and downstream polyolefins have once again diverged, with upstream and downstream failing to coordinate efforts. Intermediate industrial products, such as rubber and plastic products, are actively destocking. This stage is positioned in the "recession" phase of the Merrill Lynch clock, characterized by declining demand and inventory, resulting in decreased revenue for enterprises. The upstream polyolefin raw materials are in a passive restocking phase, situated in "stagflation," where the fundamentals are also weak, leading to price declines.

Since 2025, the spot and futures prices of polyolefins have been fluctuating downward. In July, both experienced a synchronized active destocking phase, leading to continuous bottoming out in August, and the polyolefin market remains in a difficult situation. In September, October, and November, prices continued to weaken, with November setting a new annual low. It is expected that December will continue to experience weak fluctuations, with a high probability of further declines to new lows. The PP2601 contract is expected to operate in the range of 6100-6500 yuan/ton, while L2601 is anticipated to be in the range of 6500-6900 yuan/ton.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

[Today's Plastics Market] General Materials Weakly Fluctuate, Engineering Materials Steadily Rise

-

U.S. Appeals Court Officially Rules: Trump Tariff Unlawful and Void!

-

Daily Review: Polyethylene Prices Under Weak Consolidation, Sellers Face Significant Pressure to Move Inventory