The expo concludes, dupont empowers china's intelligent manufacturing new ecosystem through innovation

From November 5 to 10, 2025, the 8th China International Import Expo successfully concluded in Shanghai. DuPont participated with the theme "Linking the Future, Co-creating Innovation," focusing on three dimensions: strategic upgrading, collaborative innovation, and local integration. With a new phase positioning of "Focus, Flexibility, High Performance," DuPont comprehensively showcased its deep accumulation and forward-looking layout in the field of material science.

During the exhibition, DuPont Industrial Solutions==Healthcare, Electric Mobility, and Sustainable DevelopmentThree major areas of key innovative products and advanced technologies have made a grand debut, deeply integrating with local needs, further deepening the innovative partnership with Chinese customers and attracting significant attention.

Full-link: Empowering Health Protection

Building a Strong Protective Barrier for Life and Health

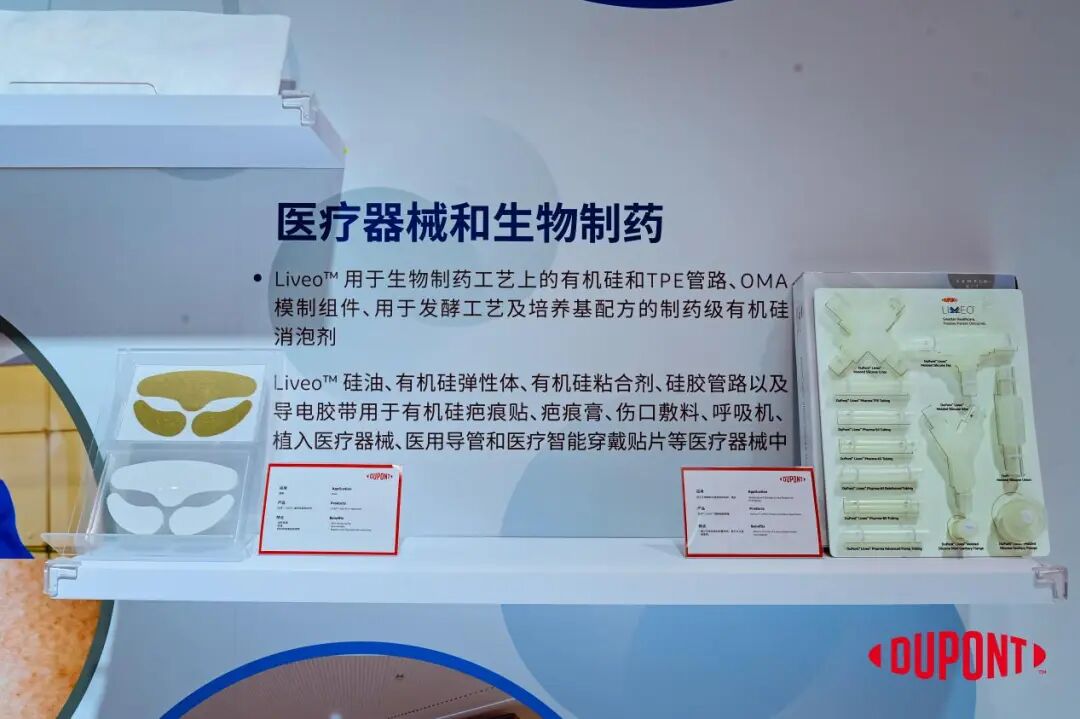

DuPont™ Liveo™ Healthcare Solutions is highly regarded in the healthcare industry.Comprehensively cover the three dimensions of pharmaceuticals, devices, and biopharmaceutical processes.In the pharmaceutical sector, this exhibition will focus on launching.Liveo™ customized topical formulations precisely focus on scar care and dermatitis treatment.In the field of medical devices, multiple high-performance new products have been showcased, breaking the precision limits of devices with breakthroughs in precision manufacturing materials, revolutionizing the experience of wearable devices with flexible bonding technology, and achieving full-scene coverage from therapeutic to consumer medical applications with eco-friendly solvents and medical aesthetics. Meanwhile, the localization process of biopharmaceutical processes continues to deepen: DuPont™ Liveo™ Pharma tubing domestic silicone tubes are continuously enriching the product matrix, and simultaneously showcased.Liveo™ Pharma TPE ultra-low temperature tubing further breaks through extreme conditions of -86℃.It provides stable and reliable fluid delivery assurance in extreme environments for cutting-edge fields such as cell therapy.

In the field of medical device manufacturing, Spectrum showcased a full range of products covering fluid management, interventional therapy and surgical techniques, specialty molding, and specialty and medical flexible materials, further demonstrating DuPont's systematic capabilities in the field of medical device manufacturing.

Qi New Materials: Driving the Electric Future

Solving the Problem of Upgrading New Energy Vehicles

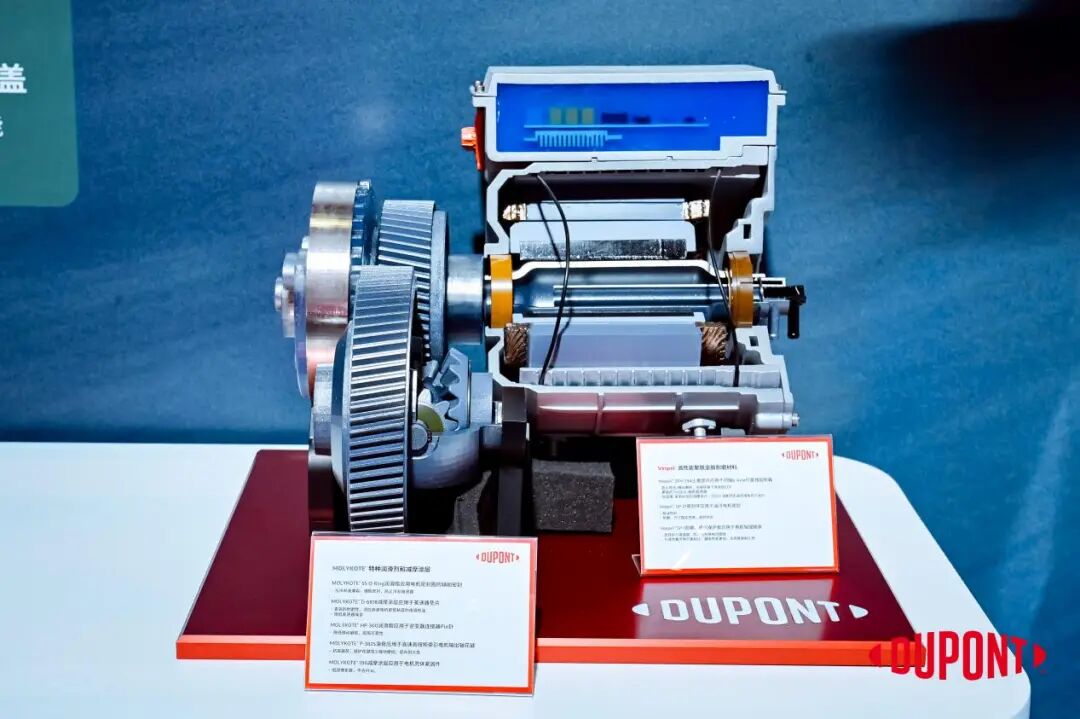

To support the high-quality development of the new energy vehicle industry, DuPont™ MOLYKOTE®Special Lubrication and Vespel®High-performance polyimide materials have demonstrated multi-dimensional friction and wear solutions in electric drive systems.MOLYKOTE®D-6818 Anti-friction CoatingRelying on a unique high-wear-resistant formula, it provides reliable anti-wear protection under oil film deficiency conditions for key components such as new energy vehicle differentials, reducing noise issues.MOLYKOTE®P-3825 Special GreaseDesigned with a special formula to enhance wear resistance, achieving long-term suppression of fretting wear on motor spline shafts.MOLYKOTE®55 O-Ring GreaseThe application of the motor cooling water jacket seal ring is compatible with the coolant, provides auxiliary sealing function, and prevents coolant leakage.

Vespel®SPV-294 Thrust WasherBy using newly developed resin, which has a higher PV (pressure-velocity) limit and high self-lubricating properties, it provides a low friction coefficient at high rotational speeds. This ensures the efficient and stable operation of the planetary gear set in the electric drive system gearbox under conditions of minimal or even no oil lubrication, preventing galling/fretting wear.

Sustainability Together: New Green Value

Driving Sustainable Development Transformation

In the field of sustainable industryDuPont drives green upgrade with cutting-edge materials. MOLYKOTE®The special lubrication series not only helps extend the service life of machinery and equipment, reduce downtime, extend maintenance intervals, and lower energy consumption, but also protects the health of construction personnel by introducing environmentally friendly solutions.MOLYKOTE®G-5133M wide temperature range grease achieves coverage of extreme temperature range from -73 to 220˚C.It does not contain intentionally added PFAS and provides full-cycle protection for wind power, aviation, and other fields.MOLYKOTE®P-1042 Adhesive Lubricating GreaseWith its excellent anti-emulsification performance, it effectively extends the service life of high-end CNC machine tool three-jaw chucks, enhances maintenance efficiency, and simultaneously promotes the harmless upgrade of accessories.

In terms of enabling industrial upgrading with advanced materials,Vespel®Precision PartsWith high wear resistance, high-temperature resistance, insulation, thermal insulation, and plasma resistance, it can effectively reduce defects in the wafer manufacturing process, improve product yield, and extend the service life of semiconductor equipment components.

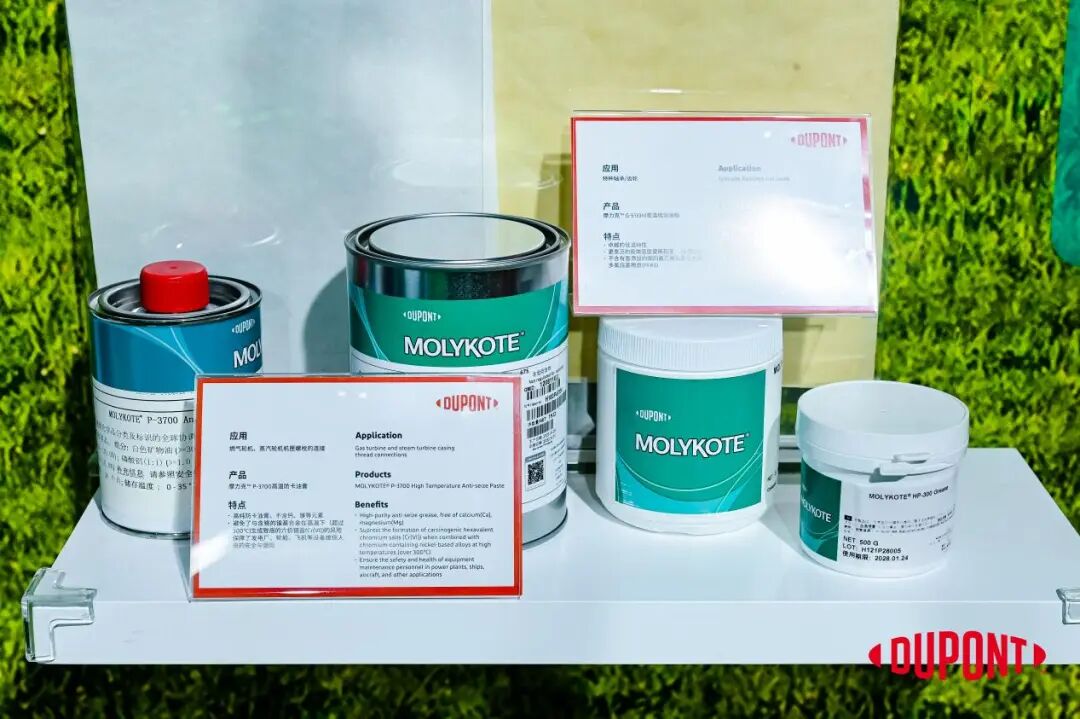

Sustainable Energy OrientedDuPont focuses on hydrogen energy, energy storage, and renewable energy innovation.Vespel®Precision componentsBy overcoming the safety bottleneck in storage and transportation with ultra-low hydrogen permeability characteristics, its unique compression modulus design further breaks through the extreme sealing barriers of liquid hydrogen. Synchronously iterative.MOLYKOTE®HP-300 Special Lubricating GreaseCertified by ISO 14687 for hydrogen purity, it ensures the integrity of the threaded connection system at 700 bar high pressure, providing reliable assurance for the entire hydrogen energy chain.

At the same time, key breakthroughs have been achieved in gas turbine maintenance technology.MOLYKOTE®P-3700 High-Temperature Anti-Seize GreaseThe use of a calcium- and magnesium-free formula eliminates the risk of hexavalent chromium salt formation, ensuring the safety of maintenance personnel while providing a human-centered operation and maintenance solution for fields such as electricity and aviation. From routine inspections to major overhauls, it safeguards equipment stability throughout the entire process. This innovative technology actively responds to the advanced reliability demands driven by the expansion of clean energy.

In the field of sustainable livingDuPont drives green transformation through innovations in printing technology.DuPont™ Cyrel®FAST Flexo Technology Celebrates 25th Anniversary MilestoneOver 1,500 installations worldwide attest to its environmental strength, reducing plate-making time by 60%-75% compared to traditional processes and lowering VOC emissions.DuPont™ Cyrel®Flat-top Dot Flexo EASYRSupport the carbon reduction transition of flexible packaging.

DuPont™ Artistri®Digital InkSynchronously developing dual-track applications: commercial inks revolutionize book and publication printing with exceptional saturation, while textile inks achieve a color revolution in garment printing through post-treatment-free technology.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Mexico officially imposes tariffs on 1,400 chinese products, with rates up to 50%

-

Progress on plastic reduction in packaging released by 16 fast-moving consumer goods brands including nestlé, pepsi, unilever, coca-cola, and mars

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories

-

By 2030, Norway's New Sorting Facilities Will Process About 80% Of The Country's Plastic Packaging Waste

-

Brazil Imposes Five-Year Anti-Dumping Duty of Up to $1,267.74 Per Ton on Titanium Dioxide From China