Balancing Cost, Performance, and Compliance: Antimony-Free Alternatives to Flame-Retardant ABS

Antimony trioxide (ATO) is affected by price fluctuations, regulatory policies, and trade uncertainties, which in turn puts pressure on ABS, the main resin. How should processing companies choose alternative materials?

Flame retardant ABS is a commonly used material in various fields such as electronics, home appliances, and automotive OEM and processing enterprises. Its balance in fire safety, impact resistance, processing performance, and compliance with UL 94 V-0 has made it applicable for decades. However, this material, along with many other flame retardant materials, contains ATO. Currently, China's dominance in antimony production, along with tariffs and geopolitical factors, has lengthened the supply cycle of ATO and raised concerns about its stability. Additionally, Europe’s REACH regulations are tightening restrictions on antimony and halogens.

This forces companies to find a balance between compliance, cost, and performance. Flame-retardant PC/ABS has become a popular choice—it retains the moldability, surface finish, and paintability of flame-retardant ABS while enhancing heat resistance and impact resistance. Although not a complete "direct replacement," it performs excellently in applications such as housings and covers.

To address industry questions, Heather Scaglione and Jared Goble from Formerra will share practical insights on antimony-free alternatives based on their corporate experience. Formerra distributes a full range of materials and provides selection consulting for plastic end markets. The two professionals have observed a significant increase in the industry's demand for antimony-free alternatives to flame-retardant ABS, as well as a growing demand for substitutes for other ATO-containing flame-retardant resins.

I'm sorry, but it seems there is no content provided for translation. Could you please provide the text you want translated?

The current rise in antimony prices and tariff policies have impacted Formerra's customers in what ways?

Scaglione:The primary impact is uncertainty. In the mold processing stage, teams often cannot obtain complete Critical to Quality (CTQ) characteristics from the Original Equipment Manufacturer (OEM), leading to a cycle in quoting—new Requests for Quotation (RFQs), constantly adjusted assumptions, and repeated quoting. It is difficult for the work to convert into actual orders because no one can determine whether the OEM will approve material changes, nor is it clear what compromises they will accept in terms of fluidity, shrinkage rate, or appearance. This uncertainty is precisely the main reason for resource consumption.

Goble:At the original equipment manufacturer (OEM) level, there are almost no completely "directly replaceable" materials. For example, in certain projects, flame-retardant ABS containing ATO can still achieve stricter ratings in thin-wall applications—such as the UL 94 5VA standard at specific thicknesses—while alternative materials find it difficult to achieve this. This forces companies to make a choice: either modify the design or select higher-performance materials. Whichever path is chosen will increase time costs, re-certification costs, and overall expenditures.

Source: Formerra

Question 2

Which industries (electronics, automotive, home appliances, etc.) are facing the greatest pressures?

Goble:Firstly, the wire and cable industry is highlighted because many compounds in this sector not only require a high amount of flame retardants but also have a large scale of usage. Secondly, the electronics and electrical industry, which widely uses engineering-grade styrenic materials and blends, is actively evaluating halogen-free solutions. As manufacturers continue to expand their range of halogen-free products, polyamide (PA, nylon) and polybutylene terephthalate (PBT) are also being considered. Additionally, considerations related to perfluoroalkyl substances (PFAS) complicate some projects since certain PFAS additives are used for dispersion purposes.

Scaglione:The home appliance and consumer electronics industry is taking proactive actions because the components of these products must meet safety rating requirements as well as aesthetic standards. Coating properties, glossiness, and color consistency are fundamental requirements, and any alternative materials must ensure flame retardancy while meeting these aesthetic criteria.

Question 3

Besides PC/ABS, what other types of plastics can practically serve as antimony-free alternatives?

Scaglione:In suitable applications, antimony-free polyamide (PA) and antimony-free polyvinyl chloride (PVC) have become mature alternative options. However, each of these materials has specific processing considerations: for example, polyamide (PA) requires drying and degassing treatment, while polyvinyl chloride (PVC) requires attention to corrosion control and temperature control; moreover, appearance requirements may further narrow the range of options.

Goble:Flame-retardant PBT and flame-retardant polyethylene terephthalate (PET) perform reliably in many electrical applications, especially for companies that wish to retain the base polymer and only replace the flame-retardant system. In the polyolefin field, magnesium hydroxide and phosphorus-based flame-retardant pathways are common choices for antimony-free solutions, but special attention must be paid to the amount of flame retardant added, material flowability, and component structural design.

Question 4

Flame-retardant PC/ABS can only replace flame-retardant ABS, or can it also replace other categories of flame-retardant materials containing ATO?

Goble:In injection molded parts, only minor adjustments to the mold are required for flame-retardant PC/ABS to replace most flame-retardant ABS. However, attention must still be paid to weld lines, venting effectiveness, and thickness requirements. In a few cases, it can also replace flame-retardant polypropylene (PP) or flame-retardant high-impact polystyrene (HIPS), but this is only applicable in scenarios where the design requires stricter tolerances, thinner wall thickness, or higher flame retardance and heat resistance, and where compromises in cost and density are reasonable. Some companies even choose pure PC materials as long as they meet specification requirements. Currently, companies are more willing to switch materials, making flame-retardant PC/ABS a practical transitional solution to avoid reliance on ATO in mass applications.

Scaglione:For most flame-retardant ABS projects, flame-retardant PC/ABS is the easiest upgrade option—it not only retains the original appearance, paintability, and molding characteristics but also enhances heat resistance and impact margin. Formerra has multiple supply channels and can provide natural color, black, UV-stabilized, and pre-colored products. However, it is not a universal solution: due to the effect of ATO, some flame-retardant ABS compounds can achieve higher flame-retardant ratings under the same thin-wall conditions. If components must meet specific ratings (such as UL 94 5VA) at a fixed thickness, structural design adjustments or other material categories may be required.

Question 5 Translate the above content into English and directly output the translation result without any explanation.

Are there any customers who have successfully tried these alternative materials?

Scaglione:Small home appliance and consumer product companies are taking the most active actions, with frequent testing activities. We have found that manufacturers have a strong demand for samples, and some product lines are even struggling to maintain inventory. This indicates that the companies' evaluation scope is broad, but it also means that if a project requires specific colors or UV-stable formulations, it is advisable to submit requests as early as possible.

Goble:We are assisting several clients in advancing the switch from flame-retardant ABS to flame-retardant PC/ABS. At the same time, material switches within the same base polymer category are also underway—such as transitioning from flame-retardant PET or flame-retardant PBT to antimony-free versions, and similar switches are being promoted for flame-retardant polyamide (PA). These switches are less difficult because the base resin remains unchanged. In addition, economic factors are also a driving force: as the cost gap between traditional materials and alternative materials continues to narrow, the commercial threshold has become lower than ever.

Question 6

In practical applications, how do the mechanical properties, processing properties, and appearance properties of flame-retardant PC/ABS compare to those of flame-retardant ABS?

Goble:Flame-retardant PC/ABS generally exhibits better heat resistance and impact resistance, especially in low-temperature environments. Its fluidity may be similar to that of flame-retardant ABS, but for components with complex structures or long flow paths, special attention should be paid to weld line strength and exhaust effectiveness. Additionally, flame-retardant PC/ABS must undergo drying treatment and must strictly comply with drying specifications.

Scaglione:The flame-retardant PC/ABS exhibits excellent appearance, particularly in terms of gloss and color depth. However, for very light colors, stricter compound control and standardized color management are required. As long as the surface pretreatment remains consistent, coating, printing, and marking processes can usually be directly applied. If the gate design and holding pressure parameters are adjusted according to the resin characteristics, its dimensional stability can be comparable to that of flame-retardant ABS.

Source: Formerra

Question 7

When enterprises abandon the use of antimony materials, they need to weigh which performance compromises (cost, impact resistance, coloring ability, surface finish, dimensional stability).

Scaglione:There are three key issues that determine the choice of alternative paths:

Can the flame retardant rating be met at the target thickness (e.g., achieving UL 94 V-0 standard at the thinnest wall)?

Due to some antimony-free packaging changing viscosity and ventilation requirements, will the parts be filled and packaged the same way on the existing tools?

Can the original colors be reproduced, especially white or light gray?

Goble:The main limitation is that some flame-retardant ABS grades containing ATO can still achieve higher flame-retardant ratings than flame-retardant PC/ABS under thin-wall conditions. If the wall thickness is fixed, companies can only choose the following options: adjust the structural design, accept a lower rating within permissible limits, or opt for higher-performance material categories.

Question 8

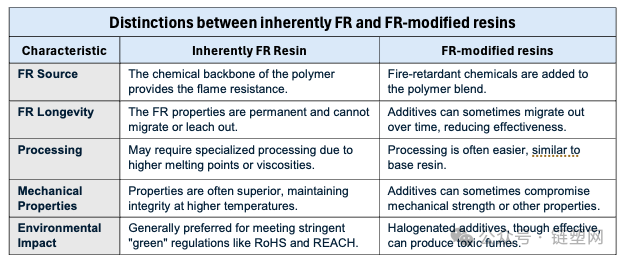

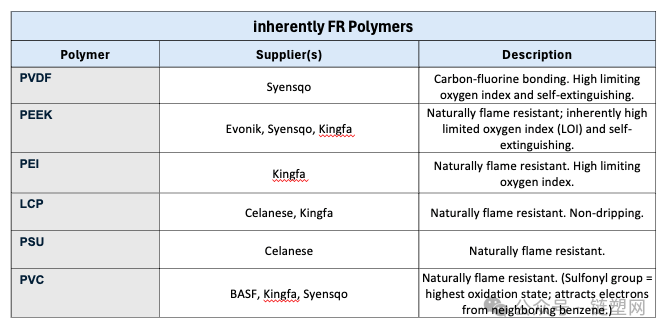

Despite the higher cost per pound of intrinsic flame-retardant resins such as polysulfone (PSU), liquid crystal polymer (LCP), and polyetherimide (PEI), in what scenarios do they still remain viable?

Goble:These materials have significant advantages in applications involving micro devices, thin-walled components, and high-temperature areas. Traditional flame-retardant composites may not pass the glow wire test or UL 94 standards without increasing the wall thickness, which can lead to increased weight and affect cooling efficiency. In such scenarios, intrinsic flame-retardant resins can meet standard requirements while maintaining or even reducing wall thickness. However, in large-scale applications, flame-retardant PC/ABS is still almost the preferred choice.

Scaglione:Additionally, these materials can also meet regulatory compliance requirements in different regions. The trade-offs lie in color (usually amber or neutral), higher processing temperatures, and special demands on supply chain planning. The decision to use such materials is often related to "value density"—when the functionality of the component and compliance risks are sufficient to justify the cost of the resin, it can solve multiple problems at once.

Question 9

What is the impact of European regulations (REACH) on the transition to antimony-free solutions?

Scaglione:These regulations have accelerated the evaluation process for alternative materials. Even if traditional flame retardant solutions remain compliant on a technical level, customers are choosing halogen-free or antimony-free materials as standard solutions for projects aimed at the European market to avoid the need for re-certification in the future.

At the same time, the documentation requirements have become more stringent. The project requires explicit disclosure of the composition of the flame retardant system and all intentionally added substances. At the initial stages of evaluation, we ensure that candidate materials comply with relevant European testing standards (such as the Glow Wire Test and the Comparative Tracking Index Test) to prevent unexpected issues later on.

Question 10

Are North American clients proactively driving transformation, or are they primarily responding passively to cost pressures?

Goble:In the North American market, cost fluctuations are the initial triggering factor. However, once companies understand the testing requirements and regulatory framework, many opt to uniformly adopt antimony-free materials within performance allowances to avoid subsequent re-validation. Compared to previous cycles, companies now have a stronger proactive response awareness — if it can be avoided, no one wants to undergo two rounds of certification.

Question 11

What are the advantages of working with Formerra to test, validate, and adopt these alternative materials compared to working directly with suppliers?

Scaglione:Our material combinations offer both depth and breadth, providing multiple material solutions for the same objective. Whether it's PC/ABS, ABS modified materials, PBT, PET, polyamide (PA), polyvinyl chloride (PVC), or intrinsic flame-retardant materials, we can provide them all and match each solution with regional standards, thickness requirements, and appearance criteria. For example, if a candidate material fails the glow wire test or does not meet color requirements, we can directly switch to other material categories or flame-retardant systems without having to restart the entire screening process.

In addition, we will address practical issues such as drying requirements, exhaust guidance, coating and adhesion testing, color control, etc., to ensure that the test conditions are consistent with production conditions, thereby reducing unexpected situations and speeding up the Production Part Approval Process (PPAP) or similar certification processes.

Goble:In simple terms, our services go beyond recommending materials. We develop sampling plans, provide processing guidance, and identify alternative supply sources where possible. Additionally, we can match each candidate grade and component thickness with regional standards such as UL 94, International Electrotechnical Commission (IEC) 60695, Glow-Wire, Comparative Tracking Index (CTI), Relative Thermal Index (RTI), and Federal Motor Vehicle Safety Standard 302 (FMVSS 302), allowing customers to avoid guessing which antimony-free solution will retain their existing certifications. Ultimately, this model reduces process cycles and shortens the cycle from quotation to part validation.

Miniaturization of electronic devices for conversion

Miniaturization typically drives electrical and electronic design towards tighter packaging, thinner walls, and higher thermal concentration. Consider micro enclosures and internal subcomponents where every millimeter counts. FR ABS starts to deform at these temperatures or fails the glow wire test, so switching to FR PC/ABS is almost a given. Components suitable for the switch include:

For compact electronic productsInternal and external shellRouter, game console, tablet, smart home hub, and handheld scanner.

The temperature often rises.Battery and power enclosureFire safety clearances are crucial.

Switches, plugs, and socketsSitting in a small footprint, it combines electrical isolation and mechanical durability.

Connectors, terminal blocks, and relay housingsNeed dimensional stability and heat creep resistance.

Small household appliances and HVAC components inMotor or fan control housingThe space is limited, but the airflow and heat load are high.

Medical device shellPortable monitors, diagnostic handheld devices, and power supplies, whose thin walls and repeated sterilization cycles comply with regulatory flame requirements.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Brazil Imposes Five-Year Anti-Dumping Duty of Up to $1,267.74 Per Ton on Titanium Dioxide From China

-

Mexico officially imposes tariffs on 1,400 chinese products, with rates up to 50%

-

MOFCOM Spokesperson Answers Questions from Reporters on China-U.S. Kuala Lumpur Trade Consultations Joint Arrangement

-

China-U.S. Summit in Busan Tomorrow! Syensqo Launches New PAEK Material; Ascend Debuts at Medical Summit

-

"Golden October" Weak, Polyethylene Prices Hit New Low of the Year in October